- 10 -

bm44d1ea

6.2

Water connection

The wire feed unit with water connection is equipped with a detection system

ELP

(

E

SAB

L

ogic

P

ump) which checks that the water hoses are connected. When

connecting a water-cooled welding gun, the water pump starts.

Detection only works with power sources that are equipped with ELP.

6.3

Wire feed pressure

Start by making sure that the wire moves smoothly through the wire guide. Then

set the pressure of the wire feeder's pressure rollers. It is important that the

pressure is not too great.

Fig 1

Fig 2

To check that the feed pressure is set correctly, you can feed out the wire against

an insulated object, e.g. a piece of wood.

When you hold the gun approx. 5 mm from the piece of wood (fig. 1) the feed

rollers should slip.

If you hold the gun approx. 50 mm from the piece of wood, the wire should be

fed out and bend (fig. 2).

ÏÏ

ÏÏ

ÏÏ

ÏÏ

ÏÏ

ÏÏ

ÏÏ

ÏÏ

ÏÏ

ÏÏ

ÏÏ

ÏÏ

6.4

Replacing and inserting wire

S

Open the side panel.

S

Disconnect the pressure sensor by folding it backwards, the pressure rollers

slide up.

S

Straighten out the new wire 10-20 cm. File away burrs and sharp edges from the

end of the wire before inserting it into the wire feed unit.

S

Make sure that the wire goes properly into the feed roller's track and into the

outlet nozzle and the wire guide.

S

Secure the pressure sensor.

S

Close the side panel.

6.5

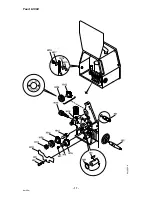

Changing feed rollers

S

Open the side panel.

S

Disconnect the pressure sensor (1) by folding it

backwards, the pressure rollers slide up.

S

Disconnect the pressure rollers (2) by turning the

axle (3) 1/4 turn clockwise and pulling out the axle.

The pressure rollers disconnect.

S

Disconnect the feed rollers (4) by unscrewing the

nuts (5) and pulling out the rollers.

GB

Summary of Contents for Aristo Series

Page 12: ...Edition 110308 Diagram 12 bm44e ...

Page 13: ...Edition 110308 13 bm44e ...

Page 15: ... 15 p ...

Page 17: ...Feed L3004 17 bm44w ...

Page 22: ... 22 notes NOTES ...

Page 23: ... 23 notes NOTES ...