4 MIG/MAG WELDING

0460 896 274

- 18 -

© ESAB AB 2013

4

MIG/MAG WELDING

Main menu → Process

MIG/MAG welding melts a continuously supplied filler wire, with the weld pool being

protected by shielding gas.

Pulsing is used to influence the transfer of the droplets from the arc so that it remains stable

and spatter-free, even with low weld data.

For wire diameters that can be used for

MIG/MAG

welding with

SHORT-/SPRAYARC

and

with

PULSING

, see the "WIRE AND GAS DIMENSIONS" appendix at the end of this manual.

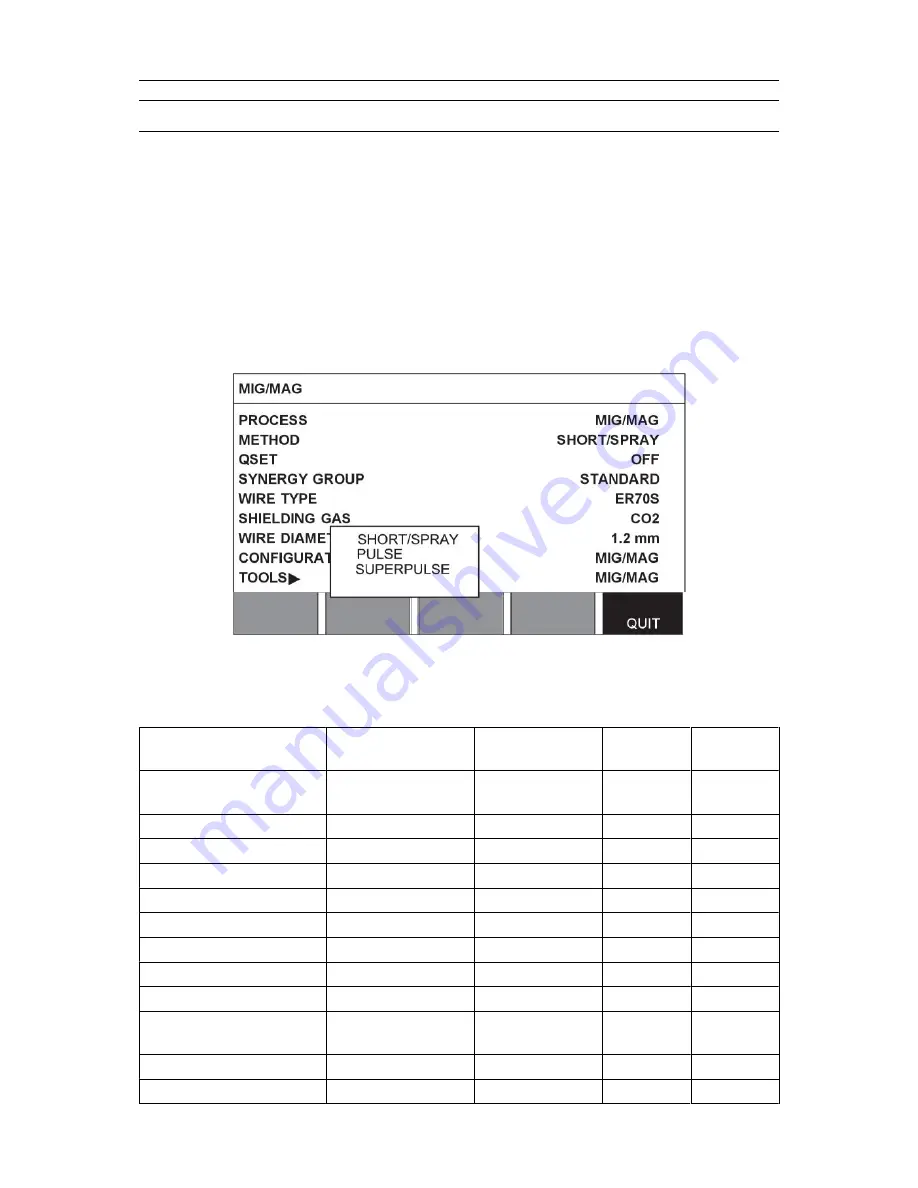

When the MIG/MAG process is selected, you can choose between four methods by selecting

Method with the left-hand knob and then pressing ENTER. Choose between short-/sprayarc,

puls or superpulse and then press ENTER again.

4.1

Settings in the weld data setting menu

4.1.1

MIG/MAG welding with short-/sprayarc

Settings

Setting range

In steps of

Synergy

dependent

Adjustable

in synergy

Voltage

8 - 60 V

0.25 V (displayed

with one decimal)

x

x

Wire feed speed**

0.8 - 30.0 m/min

0.1 m/min

x

Inductance

0 - 100%

1%

x

x

Regulator type

1 - 12

1

x

-

Synergy*

OFF or ON

-

-

-

Gas pre-flow

0.1 - 25 s

0.1 s

x

Creep start

OFF or ON

-

x

“Hot start”

OFF or ON

-

x

“Hot start” time

0 - 10 s

0.1 s

x

“Hot start” wire feed

Complete wire feed

range

0.1 m/min

x

“Touch sense”

10 - 16 A

Soft start

OFF or ON

-

x

Summary of Contents for Aristo U82

Page 1: ...Aristo Instruction manual 0460 896 274 GB 20130902 Valid from program version 1 15A U82 ...

Page 80: ...MENU STRUCTURE 0460 896 274 80 ESAB AB 2013 MENU STRUCTURE ...

Page 81: ...MENU STRUCTURE 0460 896 274 81 ESAB AB 2013 ...

Page 82: ...MENU STRUCTURE 0460 896 274 82 ESAB AB 2013 ...

Page 83: ...MENU STRUCTURE 0460 896 274 83 ESAB AB 2013 ...

Page 84: ...MENU STRUCTURE 0460 896 274 84 ESAB AB 2013 ...