11

adjustment can be made after the wire feed is put into

operation. Note that a light silver-colored spring

(182W55) is installed on the accessory support for

use with soft and small diameter hard wire. For large

diameter hard wire, replace this spring with a heavy

blue- colored spring (182W54) supplied with the unit.

SECTION 2

INSTALLATION

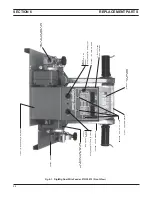

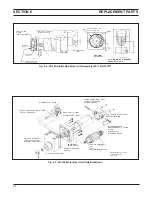

F. WATER KIT (Optional see Fig. 6-7)

Mount bulkhead adaptor (58V75) behind opening pro-

vided in rear vertical support plate, below gas connec-

tions, and secure with screws (No. 8 - 32 x 3/8-in.) and

lockwashers provided. Attach coupling and adaptor

(11N16) to the bulkhead adaptor. Mount torch cable

adaptor (45V11) on welding power stud. Connect water

drain hose to this adaptor, and water inlet hose to

adaptor 11N16.

SECTION 3

OPERATION

3.1 GENERAL

Do not allow metal-to-metal contact between the

wire feeder chassis and a metal surface connected

in any way to a welding ground. With such contact,

a poor welding ground connection may create a

difference In potential that sends part of the welding

current through the safety ground wiring in the

control cable and wire feeder, resulting in burnout of

that wiring and/or damage to wire feeder circuitry. If

the safety ground burns out, the operator may be

exposed to 115V. shock hazard.

3.2 DESCRIPTION/FUNCTION OF CONTROL FEA-

TURES

1. Power Switch.

This two-position toggle switch turns

power “on” or “off’ to the wire feeder control.

NOTE: Immediately after the control has been turned

“on” various numerical code data (e.g.; Pro-

gram I.D., Power Source and Slope) will appear

in the IPM and VOLTS display windows for 4-

seconds. After this delay, the preset weld pa-

rameters for the last torch used will be shown.

This is further described in the General Trouble-

shooting Section.

2. Run-Set Key.

This "key-operated” switch must be in

the SET position to preset, vary and weld-test the

welding parameters programmed into the control

(e.g.: Sched. I (RUN), Sched. II for each torch, Spot).

After the desired results are achieved, the program(s)

can be “locked-in” by turning the key to the RUN

position. No parameter can be altered by the opera-

tor in the RUN position.

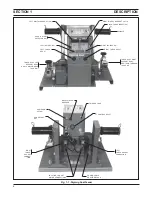

Fig. 3-1. Rear Panel Control

3. Reset Circuit Breaker.

A seven (7) ampere circuit

breaker provides protection to the 115-volt control

circuit and the wire feed motor. If an overload occurs,

the breaker will trip and suspend all operation. To

restore service, depress the breaker button to reset

the circuit.

3a.Trigger -Lock-In Switch.

This feature allows the

operator to release the torch switch (trigger lock

“on”), of the torch being used, after starting the weld

cycle. To stop the welding cycle, you simply de-

press the torch switch again, and all welding action

ceases. When this function is selected (on), it

“locks-in” both torches and their selected schedule.

It will also automatically override a Spotweld opera-

tion (if programmed). An indicator light (LED) on the

front panel lights when this feature is engaged. In

the “off” position this feature in not functional, and

the LED is off.

3A

1

3

2

Summary of Contents for Digimig Dual

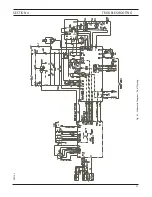

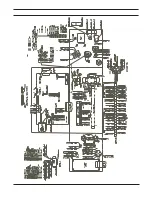

Page 21: ...21 SECTION 4 TROUBLESHOOTING Fig 4 1 Schematic Diagram Dual Digimig 30914 L ...

Page 22: ......

Page 29: ...29 NOTES ...

Page 30: ...30 NOTES ...