12

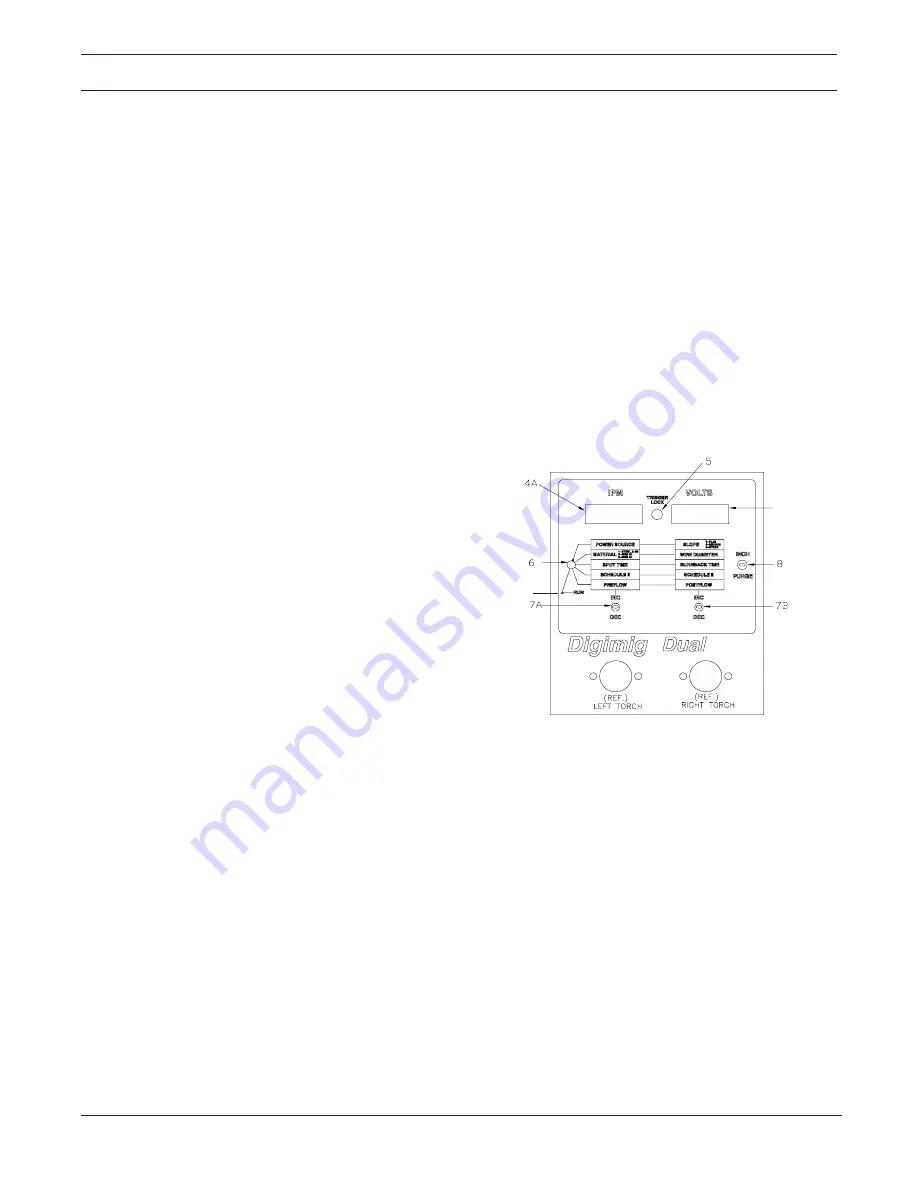

4. Digital Readout Windows.

Two individual three-

digit windows are provided to display preset or actual

welding parameters as follows:

a. IPM Digital Readout.

This window is primarily

used to display wire feed speed in IPM from 20 to

999 inch per minute in one inch increments. How-

ever, with the appropriate Rotary function actu-

ated, this window can also display the following:

— Power Source selection designated by the nu-

merals “300”, “450” or “650” (see Rotary Switch

Item 6)

— a code number that indicates the MATERIAL

selection programmed for various welding wire

applications; #1, #2, or #3 (see Rotary Switch

Item 6)

— shielding gas PREFLOW from .1 to 99.9 sec-

onds in one tenth of a second increments.

— SPOT welding time for each Torch, from .1 to

99.9 seconds in one tenth of a second incre-

ments.

— cold wire INCH speed in IPM from 40 to 999

inches per minute in one inch increments. Please

note the initial starting speed jumps to 100 ipm

for 2-seconds and then goes to preset value.

NOTE: When power is first turned “on” (but not welding)

the display windows will initially show the Pro-

gram I.D. numbers for 1 second and then flash

the Power Source and Slope selections for 3-

seconds (to make sure that the correct power

source and slope are being used). Then, the

IPM window will “continuously” read Preset wire

speed if the Rotary switch is in the RUN or SCH.

II mode. When the arc is struck, the IPM window

will then continuously read Actual welding wire

speed.

b. Volts Digital Readout.

This window is primarily

used to display arc voltage in VOLTS from 12 to 50

vdc in one tenth volt increments. However, with the

appropriate Rotary function actuated, this window

can also display the following:

— indicates power source SLOPE selected and

designated by the numeral 1, 3 or 6 (see Rotary

Switch Item 6)

— a pair of numbers represent WIRE DIAMETER

sizes which are programmed for selection as

follows: #30, #35, #45, #52 or #63 (see Rotary

Switch Item 6).

— shielding gas POSTFLOW from .1 to 99.9 sec-

onds in one tenth of a second increments.

— manual BURNBACK time. Manually adjustable

burnback time period which when preset will

override the automatic adaptive anti-stick fea-

SECTION 3

OPERATION

ture. This time period will be set In one-cycle (60

cycle = 1 sec.) Increments. When set to “zero”,

the Automatic Anti-stick feature will be opera-

tional.

NOTE: When power is first turned “on” (but not welding)

the display windows will initially show the Pro-

gram I.D. numbers for 1 second and then flash

the Power Source and Slope selections for 3-

seconds (to make sure that the correct power

source and slope are being used). Then, the

VOLTS window will “continuously” read Preset

voltage if the Rotary Switch is in the RUN or

SCH. II mode. When the arc is struck, the

VOLTS window will then continuously read Ac-

tual welding voltage.

5. LED Light.

This LED lights to indicate that Trigger-

Lock-In is engaged.

IMPORTANT

To setup the torches for programming, simply oper-

ate and release the torch switch lever for one torch

and preset the desired parameters. Then, repeat

this procedure with the remaining torch to preset its

welding parameters. Under normal operation, the

control’s memory will always “default” to the torch/

parameters last used during the preceding welding

operation. When the unit is initially turned “on” or

“reset”, the “right” torch is the dominant or “de-

fault” torch.

6. Rotary Switch.

This six (6) position switch allows

you to select a “pair” of welding parameters per

position as follows:

a. Position 1, Power Source/Slope (Must be set).

This position must match the

Power Source

used,

and its Slope setting. These selections will be

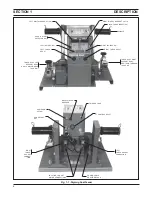

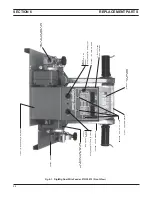

Fig. 3-2. Front Panel Controls

Pos. #6

¾

4B

Positions

#1

#2

#3

#4

#5

Summary of Contents for Digimig Dual

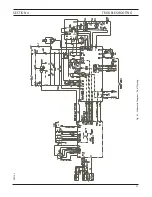

Page 21: ...21 SECTION 4 TROUBLESHOOTING Fig 4 1 Schematic Diagram Dual Digimig 30914 L ...

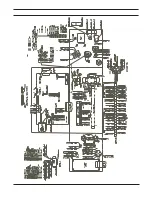

Page 22: ......

Page 29: ...29 NOTES ...

Page 30: ...30 NOTES ...