20

SECTION 3

OPERATION

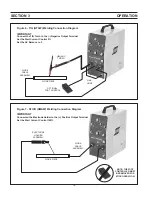

3.2.2 MMA Welding

1. Keeping the electrode/holder away from the work or

exposed metal surfaces connect the unit to the main

supply and switch the power on/off switch to “ON”.

Open circuit voltage is now present at the electrode

holder.

2. Position the electrode close to the point where weld-

ing is to start without touching the work.

3. Cover your eyes by lowering your welding hood or

handshield, warn bystanders to protect their eyes.

4. Scratch the electrode on the work surface near the

start point (as though striking a match). The arc

should strike.

5. When the arc as stabilized, feed the electrode into

the hot pool of molten metal keeping the electrode

at approximately 65-80° to the workpiece.

If the electrode “freezes”, ie. sticks to the workpiece,

gently twist the electrode and pull it free. If this is not

possible, release the electrode from the holder,

switch off the supply and cut the electrode free.

Freezing will occur if heavy contact is made with the

workpiece at too low a current setting.

6. Once the arc is successfully struck and stable, ad-

just the arc length to about the size of the electrode

diameter.

7. Weld bead size is dependent on the oscillation tech-

nique of th electrode. Typically a small ‘whipping” or

“circular” motion works best.

This combination of backward and downwards move-

ment requires skill which will be acquired after a few prac-

tice welds.

Switch off the main supply when welding is completed or

while changing electrodes.

Summary of Contents for Heliarc 161

Page 4: ...4 TABLE OF CONTENTS ...

Page 22: ...22 SECTION 4 MAINTENANCE ...

Page 26: ...26 SECTION 6 REPLACEMENT PARTS 12 9 3 4 15 5 17 18 16 8 14 13 6 7 11 10 19 20 ...

Page 28: ...28 SECTION 6 REPLACEMENT PARTS ...

Page 29: ...29 Notes ...

Page 30: ...30 Notes ...