14

IV. INSTALLATION OF POWER SOURCE

AND ACCESSORIES

4.1 LOCATION

Several factors should be considered when selecting

an installation site. Adequate ventilation is necessary

to provide cooling, and the amount of dirt and dust to

which the machine is exposed should be minimized.

There should be at least 18 inches of unrestricted space

between the Power Source's side and rear panels and

the nearest obstruction to provide freedom of air move-

ment through the Power Source.

The installation site should permit easy removal of the

Power Source outer enclosure for maintenance. In-

stalling or placing any type of filtering device will re-

strict the volume of intake air, thus subjecting the Power

Source internal components to overheating. Warranty

is void if any type of filtering device is used.

Do not operate the machine without the running

gear installed.

4.2 ASSEMBLY OF REAR WHEELS

The unit's running gear is factory assembled except

for the rear wheels which are packed loose and in the

shipping carton. The rear gear consists of two wheels,

four washers, two cotter pins, and an axle. To install

the gear, do the following:

A. Insert the axle through the holes provided at

the rear of the gear.

B. Place a washer onto each end of the axle. Slip

on the wheels and add another washer to the

outside of each wheel. Secure the whole

assembly by inserting a pin into each end of the

axle.

C. Remove the existing shipping supports by un-

screwing from chassis.

4.3 ELECTRICAL INPUT CONNECTIONS

In order to provide a safe and convenient means to

completely remove all electrical power from the Power

Source, it is highly recommended that a line discon-

nect switch be installed in the input circuit to the Power

Source.

BEFORE MAKING ELECTRICAL INPUT CONNEC-

TIONS TO THE WELDING MACHINE, "MACHINERY

LOCKOUT PROCEDURES" SHOULD BE EM-

PLOYED. IF THE CONNECTIONS ARE TO BE

MADE FROM A LINE DISCONNECT SWITCH, THE

SWITCH SHOULD BE PADLOCKED IN THE OFF

POSITION. IF THE CONNECTION IS TO BE MADE

FROM A FUSEBOX, REMOVE THE FUSES AND

PADLOCK THE COVER CLOSED. IF NO LOCKING

FACILITIES ARE AVAILABLE, ATTACH A RED TAG

TO WARN OTHERS NOT TO ENERGIZE THE CIR-

CUIT.

4.3.1 INPUT ELECTRICAL REQUIRE-MENTS

The primary input voltage requirements are shown on

the Power Source nameplate. The Power Source is

designed to be operated from a 208/230 V single-phase

50/60 Hz power supply.

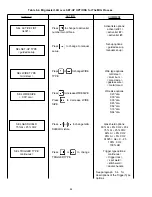

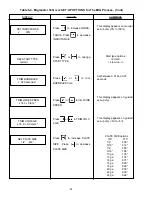

Figure 4-1. Primary Connections

4.3.2 INPUT CONDUCTOR CONNECTIONS

The input power cord is provided with an attachment

plug. The plug will mate with a 250 Volt, 50 Amp re-

ceptacle conforming to NEMA 6-50R configuration.

The receptacle should be wired to a separately fused

disconnect or circuit breaker. This disconnect or

breaker can be wired to a single-phase system or to

two conductors of a three-phase system. A third con-

ductor for grounding should also be connected between

the disconnect and the receptacle.