33

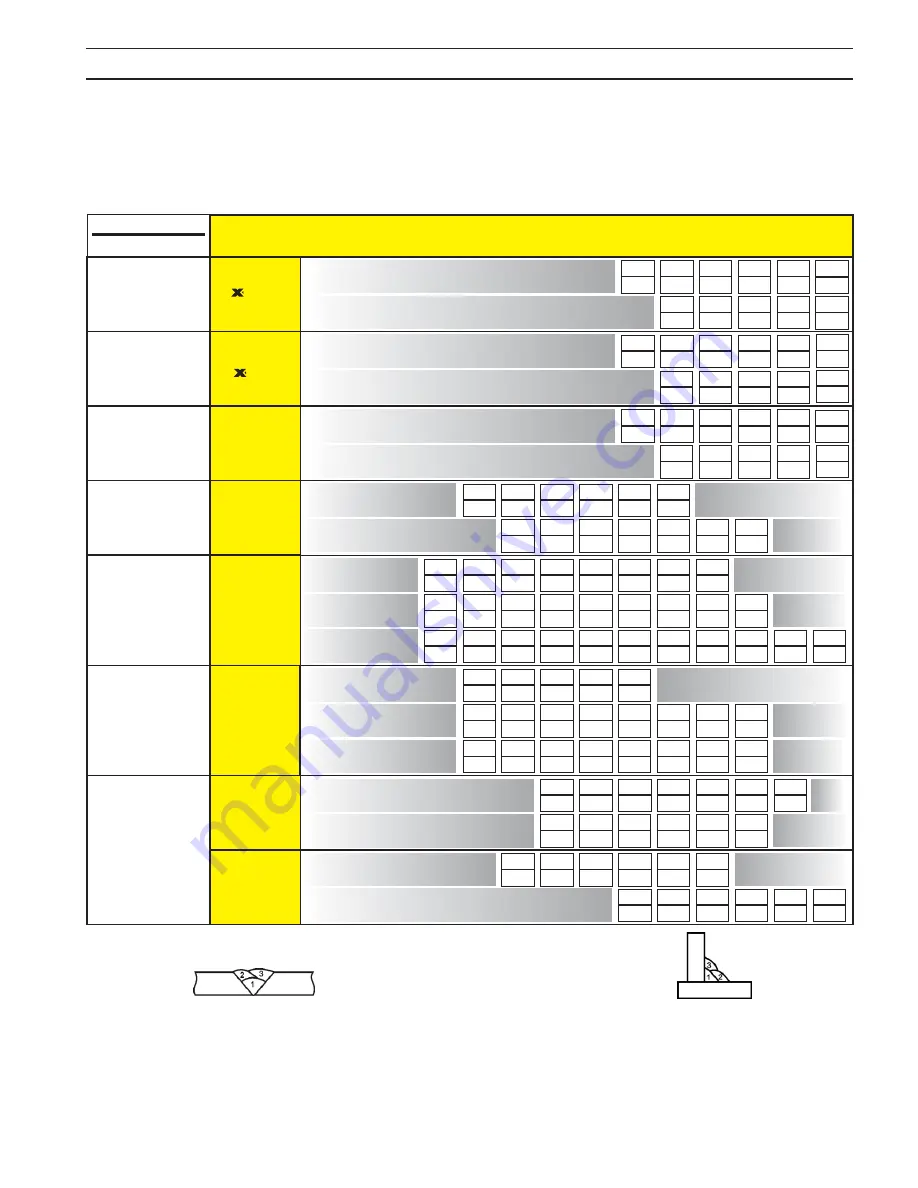

table 3 - MIg paraMeters chart

sectIon 4

operatIon

Polarity - DCEP

(Electrode Positive)

Polarity - DCEP

(Electrode Positive)

280

21

250

21

230

21

195

20

185

19.5

.030

.8mm

400

25

475

26

450

25.5

350

22

325

22

300

21

230

21

180

20

.035

.9mm

475

26

450

25.5

400

25

350

22

325

22

300

21

230

21

180

20

.045

.9mm

STAINLESS

STEEL

Arcaloy

308L, LSi, H

309L, LSi, H

316L, LSi, H

Shield Gas

Shield Gas

Shield Gas

Shield Gas

Helium TriMix

For thicknesses

above 3/16” use

98% Argon - 2% CO

2

75% Argon/25% CO

2

75% Argon/25% CO

2

100% CO

2

500

19

400

18

330

17

280

16

230

16

180

15

130

15

90

14

.030

.8mm

400

20

360

19

320

18

280

17

240

17

200

16

160

16

120

15

85

15

.035

.9mm

270

23

270

23

240

22

220

21

200

20

180

19

160

19

140

18

120

17

100

16

80

16

.045

1.2mm

CARBON

STEEL

Spoolarc 82

Spoolarc 85

Spoolarc 87

Spoolarc 86

Polarity - DCEP

(Electrode Positive)

520

26

500

26

430

25

400

24

380

24

320

23

265

22

430

28

370

27

350

26

320

26

290

26

215

24

.035

Spool Gun

.9mm

3/64”

Standard Gun

1.2mm

ALUMINUM

4000 Series

400

26

400

26

380

25

320

25

280

23

220

22

680

23

600

23

550

23

440

22

400

22

375

21

.035

Spool Gun

.9mm

3/64”

Standard Gun

1.2mm

ALUMINUM

5000 Series

100% Argon

Shield Gas

For 100% CO

2

add 2 volts

Wire Feed Speed

Volts

700

28

600

27

460

26

380

25

280

22

.035”

.9

mm

500

33

400

30

300

29

200

28

.045”

1.2

mm

CORED WIRE

Dual Shield

7100 Ultra

7100 LC

FC 717

.045”

1.2

mm

.045”

1.2

mm

.052”

1.4

mm

.052”

1.4

mm

Argon-25% CO

2

or 100% CO

2

as recommended in

product data sheet

Polarity - DCEP

(Electrode Positive)

Polarity - DCEP

(Electrode Positive)

Polarity - DCEP

(Electrode Positive)

Polarity - DCEN

(Electrode Negative)

360

17

220

17

200

24

200

23

250

25

275

24

200

25

175

23

300

26

350

25

300

26

250

24

425

29

450

26

400

28

300

25

475

30

500

27

450

29

350

26

550

30

600

29

785

29

500

30

400

27

550

33

170

17

150

16

110

16

80

15

.035”

.9

mm

Self-Shielding

CORED WIRE

No Shield Gas

Required

22ga.

.030”

.8mm

18ga.

.048”

1.2mm

16ga.

.060”

1.5mm

14ga.

.075”

1.9mm

12ga.

.105”

2.7mm

10ga.

.135”

3.5mm

11ga.

1/8”

3.2mm

3/16”

4.8mm

1/4”

6.4mm

5/16”

8.0mm

3/8”

9.6mm

1/2” Up

12mm

Gauge

Inches

Metric

Material

Thickness

Table Legend

20ga.

.036”

.9mm

Material Thickness

Type

STAINLESS STEEL

CARBON STEEL &

22ga.

.030”

.8mm

18ga.

.048”

1.2mm

16ga.

.060”

1.5mm

14ga.

.075”

1.9mm

12ga.

.105”

2.7mm

10ga.

.135”

3.5mm

11ga.

1/8”

3.2mm

3/16”

4.8mm

1/4”

6.4mm

5/16”

8.0mm

3/8”

9.6mm

Gauge

Inches

Metric

20ga.

.036”

.9mm

35

45

55

75

85

95 110 130 185 225 250

65-75

Sureweld 10P

Sureweld SW-15

Sureweld SW-15IP

Sureweld 7024

Atom Arc7018

Arcaloy 308L

Electrode

E6010

CARBON STEEL

E7018

E7024

E7014

E6013

E308L

60-90

120-135

150-210

130-170

80-110

145-190 170-230

70-100 100-150 160-200 190-270

130-180 180-240 250-270

70-100

90-160 130-220 200-270

40-70

70-100 100-145 130-190

STAINLESS STEEL

3/32

(2.4)

1/8

(3.2)

5/32

(4.0)

3/16

(4.8)

Inches

(mm)

Diameter

Type

130

18

130

18

125

18

100

17

80

16

70

16

54

15

.045”

1.2

mm

300

MultiMaster

00.0

125

2

1

4

3

300

MultiMaster

00.0

080

2

1

3

4

MIG - DCEN

Electrode

Negative

TIG - DCEN

Electrode

Negative

STICK - DCEP

Electrode

Positive

MIG - DCEP

Electrode

Positive

19.2

185

3

4

1

2

300

MultiMaster

CORED WIRE

Dual Shield

Series

710X

II 711X

CORED WIRE

Dual Shield

Series

II 712X

1. Determine initial settings from TIG Data Table based on material

thickness.

2. Place

WELD PROCESS

switch to the TIG (left) position.

3. While holding the

PRESET

button, adjust the

CURRENT

knob to set desired weld current in the upper digital display window.

4. Touch the tungsten electrode to the workpiece momentarily to

establish the arc. Adjust the welding current as needed for the

desired puddle control.

Note: The

WIRE SPEED

knob has no effect in TIG mode.

1

2

3

4

TIG SET-UP

1. Determine initial settings from Stick Electrode Data Table based

on electrode type and diameter.

2. Place the

WELD PROCESS

switch to the STICK (right) position.

3. While holding the

PRESET

button, adjust the

CURRENT

knob to set the desired weld current in the upper digital display

window.

4. Strike the electrode and start welding. Adjust the welding current as

needed for the desired puddle control.

Note: The

WIRE SPEED

knob has no effect in STICK mode.

1

2

3

4

STICK SET-UP

Welding Polarity - DCEP

(Electrode Positive)

Welding Polarity - DCEN

(Electrode Negative)

Shielding gas flow rate

15 - 25 cfh

When the WELD PROCESS switch is set to TIG or STICK position, the electrode will be electrically “

HOT

”.

When the WELD PROCESS is set to the MIG position, depressing the gun trigger will cause the wire

electrode to become electrically “

HOT

” and will start the feed motor to feed wire.

Do not allow the electrode to touch the work until you are ready to make a weld.

POLARITY CONNECTION GUIDE

1. Determine initial settings from MIG Data Table based on wire

type, diameter, material thickness and shielding gas.

2. Place

WELD PROCESS

switch to MIG (center) then press

PRESET

button.

3. Turn the

WIRE SPEED

knob to set desired speed in the

upper digital display window.

4. Turn the

VOLTAGE

knob to set desired voltage in the lower

digital display.

5. Pull gun trigger and start welding. Fine tune wire speed and

volts as needed for desired arc characteristics.

MIG/FCAW SET-UP

Note 1: MIG 3/8" and above setting data indicates multi-pass weld sequence with proper joint preparation required.

Note 2: FCAW above 1/2" setting data indicates multi-pass weld sequence with proper joint preparation required.

1

2

3

4

LABEL Part No. 0558954112 Rev OR - 9/07

(Refer to Instruction Literature 0558007770 for more detailed information regarding Safety, Installation, and Operation)

CoreShield 11

(Multi Pass)

CoreShield 15

(Single Pass)

MIG/FCAW

MIG/FCAW

MIG/FCAW

Use only recommended joint preparation and weld sequence

procedures found in AWS, ANSI, ASME, ASNT publications and codes.

Summary of Contents for Multimaster 300

Page 1: ...Multimaster300 300X MIG TIG STICK WELDING PACKAGE 0558007770 06 2010 Instruction Manual...

Page 4: ...4 table of contents...

Page 40: ...40 TABLE DES MATI RES...

Page 66: ...66 section 6 replacement parts...

Page 67: ...67 section 6 replacement parts 26...

Page 68: ...68 section 6 replacement parts...

Page 69: ...69 section 6 replacement parts...

Page 70: ...70 section 6 replacement parts...

Page 71: ...71 section 6 replacement parts...

Page 72: ...72 section 6 replacement parts...

Page 73: ...73 section 6 replacement parts...

Page 74: ...74 section 6 replacement parts...

Page 75: ...75 section 6 replacement parts...

Page 76: ...76 section 6 replacement parts Mulitmaster 300 Mulitmaster 300X...

Page 77: ...77 section 6 replacement parts Mulitmaster 300 Mulitmaster 300X...

Page 78: ...78 section 6 replacement parts Mulitmaster 300 Mulitmaster 300X...

Page 79: ...79 section 6 replacement parts Mulitmaster 300 Mulitmaster 300X...

Page 80: ...80 section 6 replacement parts Mulitmaster 300 Mulitmaster 300X...

Page 81: ...81 section 6 replacement parts Mulitmaster 300 Mulitmaster 300X...

Page 84: ...section 6 replacement parts...