19

Origo™ Feed 304 PIPE

5) INSTALLATION

1) Connect the wire feeder to the power source associated through the cable of command.

2) Fix the welding cable connected to the te power source in the quick connection placed in the rear

panel.

3) Install the welding gun.

4) Install the wire.

5) Install the feed rollers (see table 5.1) and the inlet and intermediate nozzles (see table 5.2) according to

the type and wire diameter to be used.

NOTE

: The feed and pressure rollers are parts subject to wear in normal

operating system, and should be substituted whenever there are signs of wear

that can prevent the correct feeding of the welding wire feeder.

N.B.

:The total range of wire diameters that the wire feeder can hold is covered by

a roller set for diameters between 1.20 to 2.00 mm; each roller has 2 grooves,

each corresponding to a wire diameter.

The pressure rollers (top) and the feed (bottom) are geared between themselves,

being as such all impellers.

Section 9 of this manual presents the complete list of components of the wire feeder mechanism.

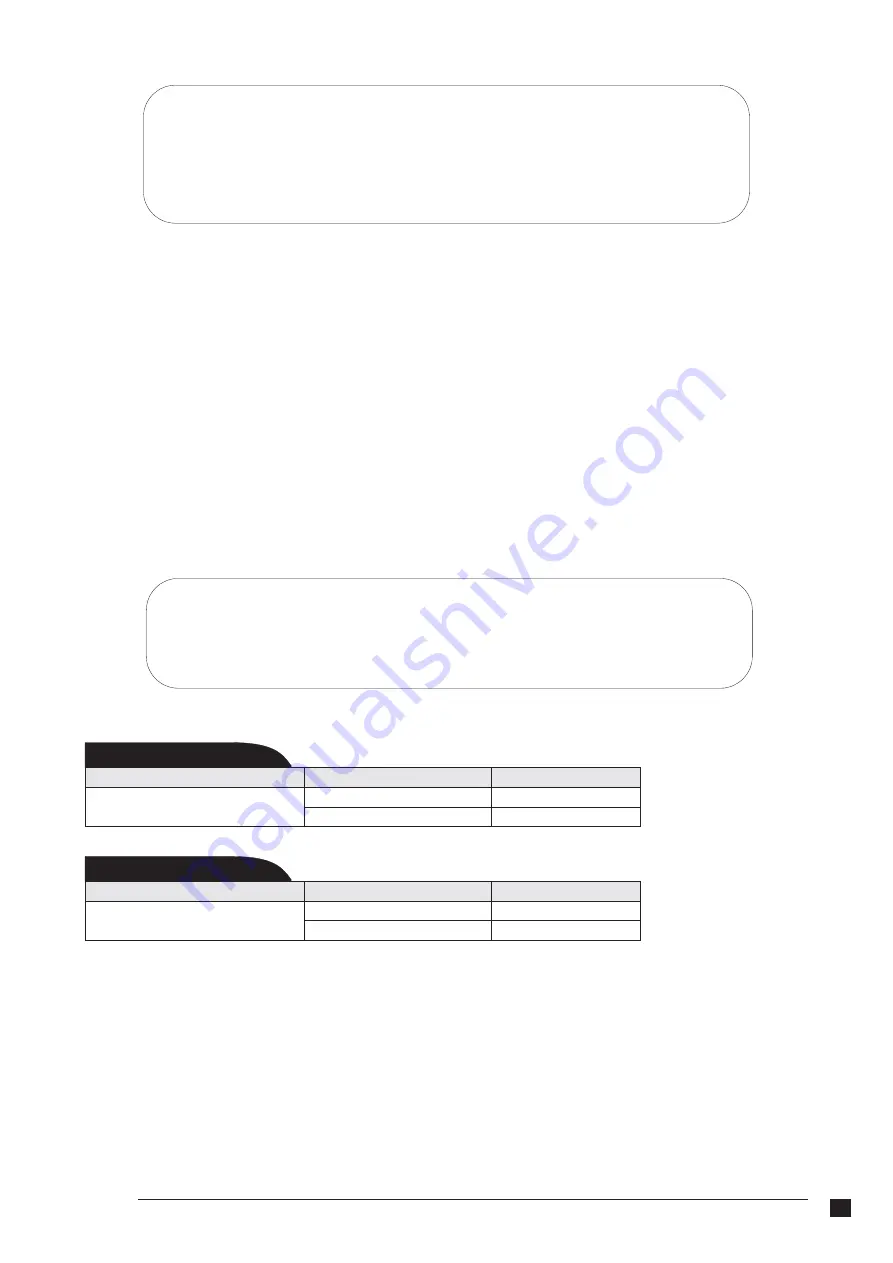

TABLE 5.1

Cover

1.20 - 1.60

1.60 - 2.00

0900121

0901204

Wire type

Diameter (mm)

Reference

TABLE 5.2

Intermediate Nozzle

1.20 - 1.60

1.60 - 2.00

0900368

0900896

Description

Wire diameter (mm)

Reference

Summary of Contents for Origo Feed 304 PIPE

Page 5: ...Origo Feed 304 PIPE 5 3 2 4 5 7 6 1 8 9 11 10 ...

Page 12: ... página em branco 12 Origo Feed 304 PIPE ...

Page 17: ...Origo Feed 304 PIPE 17 3 6 1 2 4 5 7 8 9 11 10 ...

Page 24: ...24 Origo Feed 304 PIPE blank page ...

Page 29: ...Origo Feed 304 PIPE 29 3 6 1 2 4 5 7 8 9 11 10 ...