7 TROUBLESHOOTING

0463 272 001

- 20 -

© ESAB AB 2017

7

TROUBLESHOOTING

Try these recommended checks and inspections before sending for an authorised service

technican.

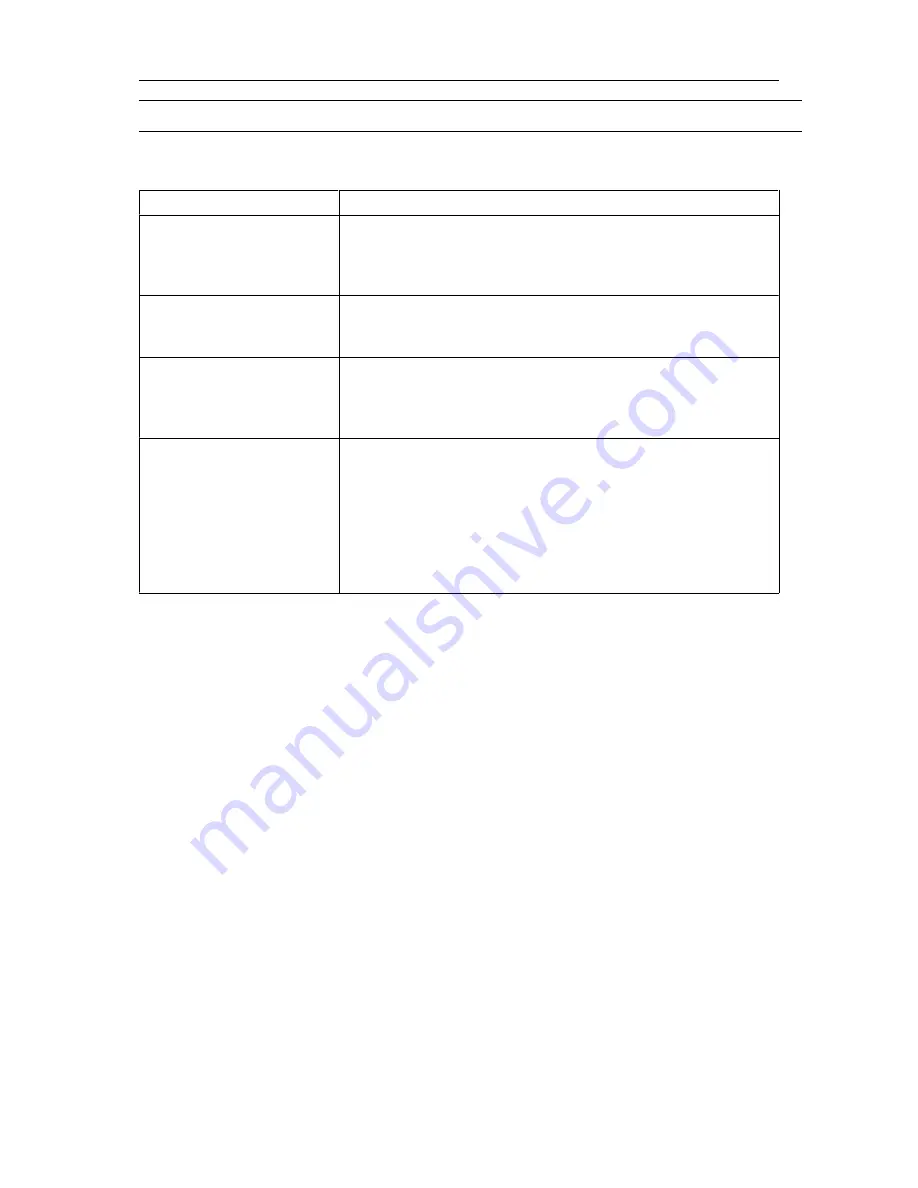

Type of fault

Actions

No arc

• Check that the mains power supply switch is turned on.

• Check that the welding current supply and return cables

are correctly connected.

• Check that correct current value is set.

Welding current is

interrupted during welding

• Check whether the thermal overload trip has operated

(indicated by the orange lamp on the front).

• Check the main power supply fuses.

Thermal overload trips

operate frequently

• Check to see whether the air filters are clogged.

• Make sure that you are not exceeding the rated data for

the power source (i.e. that the unit is not being

overloaded).

Poor welding performance

• Check that the welding current supply and return cables

are correctly connected.

• Check that the correct current value is set.

• Check that the correct welding wires are being used.

• Check the main power supply fuses.

• Check the wire feed unit - that proper rolls are applied and

properly set the pressure of the wire feeder's pressure

rollers.