Summary of Contents for Origo Mig L305

Page 2: ......

Page 11: ...4 INSTALLATION 0349 301 124 11 ESAB AB 2017 4 4 Electrical installation ...

Page 20: ...CLEANING 0349 301 124 20 ESAB AB 2017 CLEANING ...

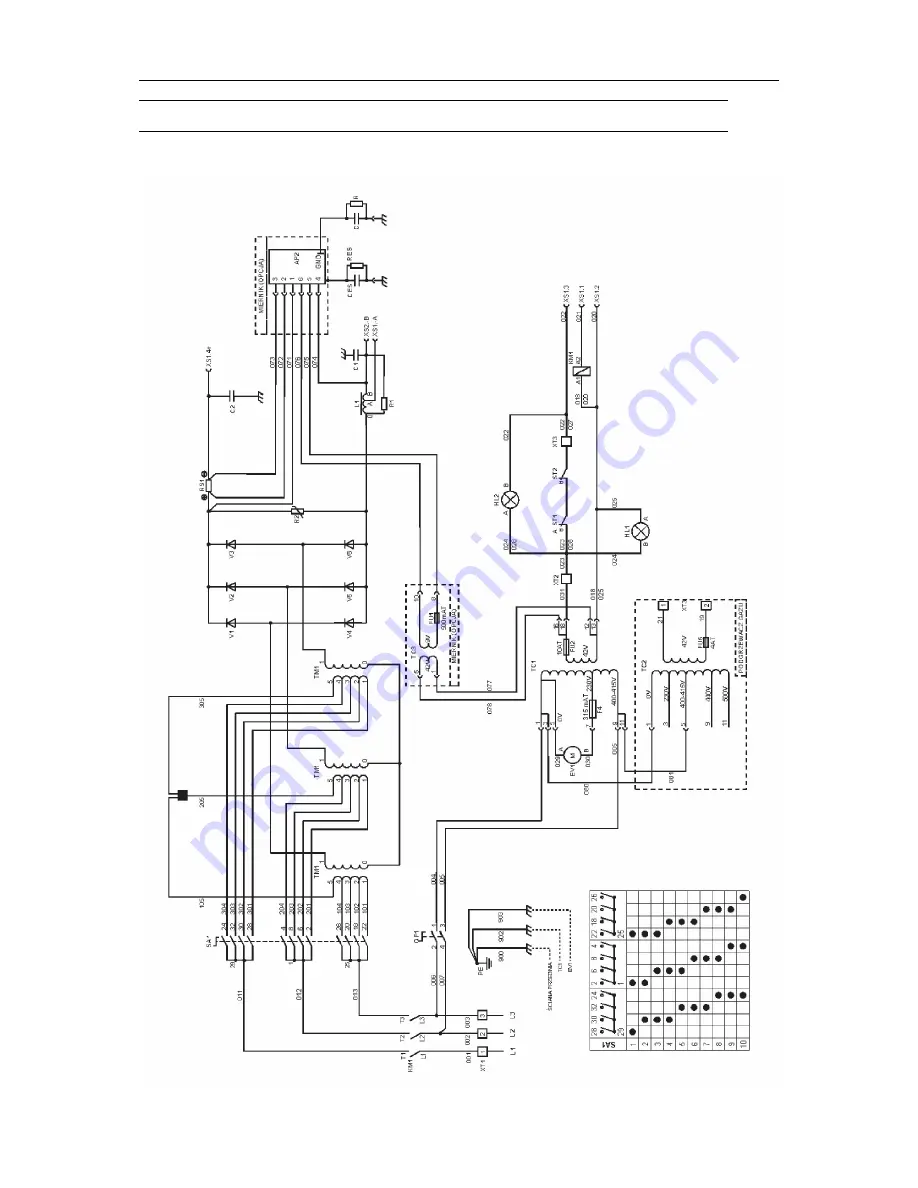

Page 21: ...DIAGRAM 0349 301 124 21 ESAB AB 2017 DIAGRAM OrigoTM Mig L305 400 415 V ...

Page 22: ...DIAGRAM 0349 301 124 22 ESAB AB 2017 OrigoTM Mig L405 400 415 V ...

Page 23: ...DIAGRAM 0349 301 124 23 ESAB AB 2017 OrigoTM Mig L405 230 500 V ...