Edition 040830

-- 26 --

ch25ie1

OPERATION

General safety regulations for the handling of the equipment can be found on

page 24. Read through before you start using the equipment!

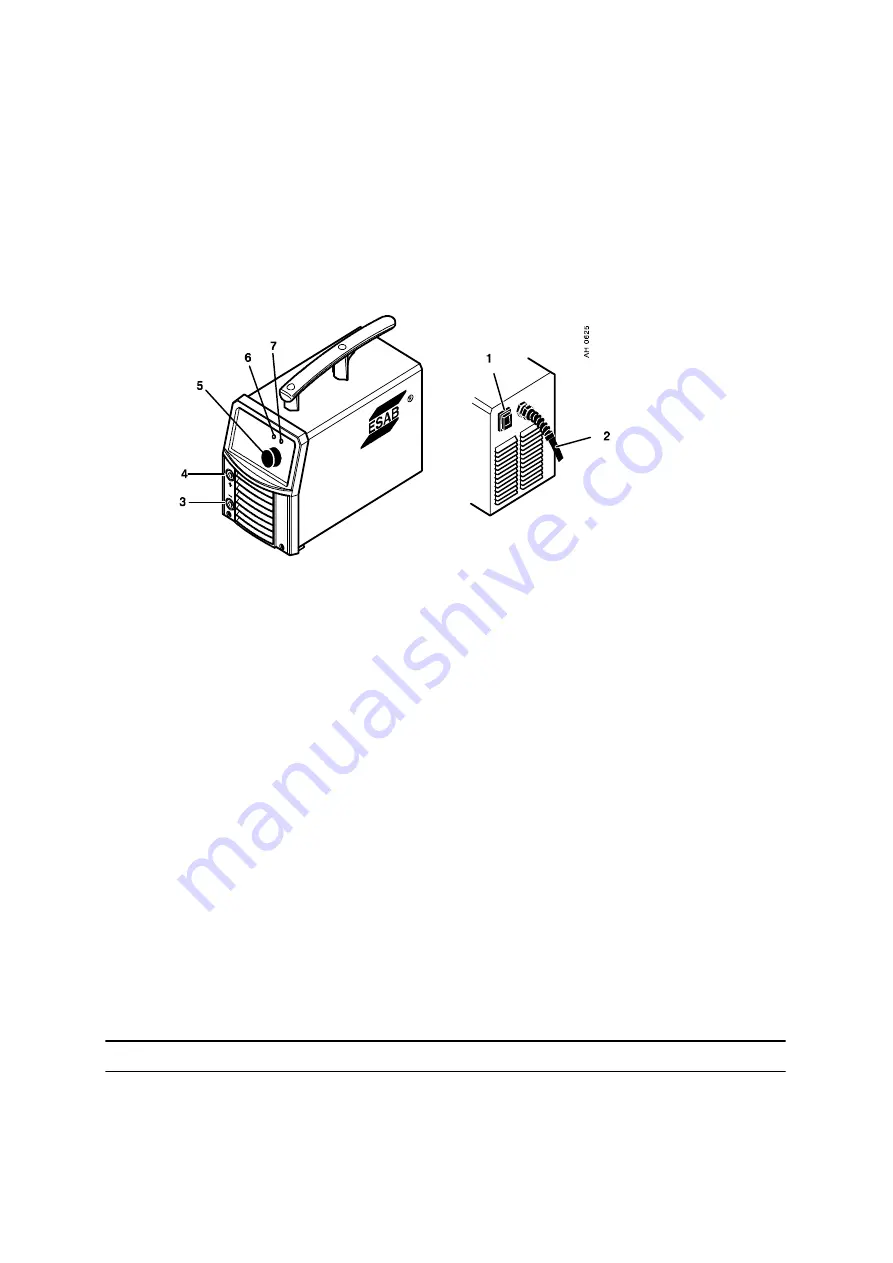

Connections and control devices

1

Mains switch

5

Knob for current setting

2

Mains cable

6

Mains voltage indicator (green)

3

Return cable connection(--)

7

Thermal overload indicator (yellow)

4

Welding cable connection (+)

Welding

The OrigoArc 150 gives direct current, and you can weld most metals to alloy and non--alloy

steel, stainless steel and cast iron. The OrigoArc 150 allows you to weld most coated

electrodes from

∅

1.6 to

∅

3.25 mm.

Overheating protection

The welding power source has a thermal overload trip which operates if the temperature

becomes too high, interrupting the welding current and lighting a yellow indicating lamp on

the front of the power source. The thermal overload trip resets automatically when the

temperature has fallen.

MAINTENANCE

Regular maintenance is important for safe, reliable operation.

Note!

All guarantee undertakings from the supplier cease to apply if the customer himself

attempts any work in the product during the guarantee period in order to rectify any faults.

The OrigoArc 150 requires little maintenance. In normal cases, it is sufficient to blow it clean

using dry compressed air once a year, but this should be done more often if it is set up in a

dusty, dirty area.

SPARE PARTS

The spare parts list for the OrigoArc 150 is published in a separate document with filename

/ ordering no. 0459 261 990.

Summary of Contents for OrigoArc 150

Page 6: ...Edition 040830 6 ch25d1 OrigoArc 150 ...

Page 7: ...Edition 040830 7 ch25d1 ...

Page 27: ... 27 notes NOTES ...