4

soda washing soda may be substituted for the sodium

carbonate. Thoroughly scrub all surfaces of the parts.

If immersion treatment is used, continuously stir the

parts in the solution for at least 10 minutes.

After washing, thoroughly rinse the parts with clear

water. Repack the valve with valve packing approved

for oxygen service.

C. MIXER DISK

If necessary, the torch mixer disk can be removed for

cleaning as follows: Remove the two hex nuts and cap

screws used to bolt the preheat mixer body to the cut-

ting oxygen block. Using a wrench, unscrew the mixer

tube connecting nut. Remove the mixer body and in-

vert it. The mixer disk will then fall out.

To clean the mixer disk center orifice, use a No. 5 drill.

To clean the outer orifices use a No. 51 drill. Other

cleaning tools tend to enlarge or bell-mouth the ori-

fices, and should not be used.

If the mixer disk is distorted or the seating surfaces

marred or scratched, it should be replaced with a new

one. In reassembling the mixer disk and mixer tube in

the torch, make sure that the seating surfaces are

clean.

D. GAUGE

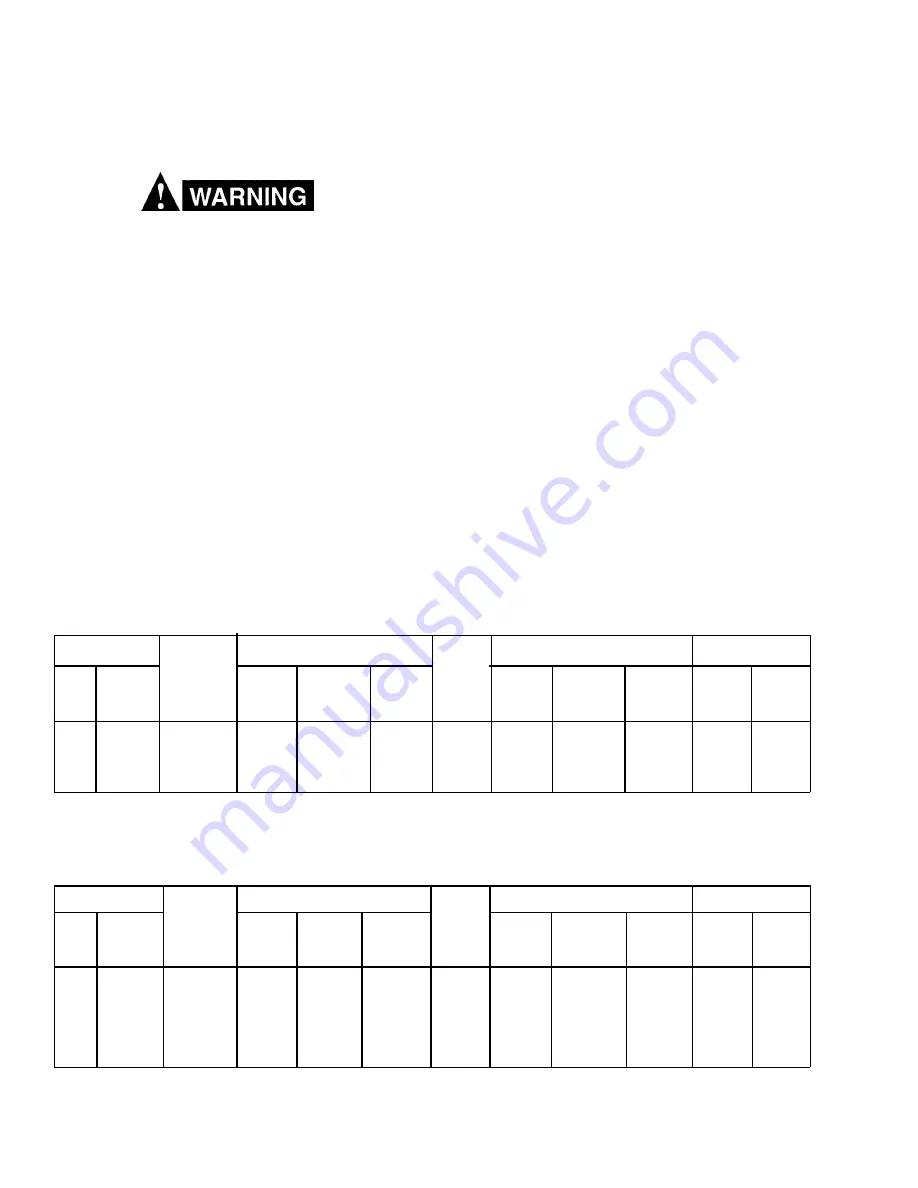

1702 Series Natural Gas Nozzles

Nozzle

Gas Pressure, psig

Gas Consumption, cfh

Cleaning Drill Size

Steel

Cutting

Cutting

Preheat

Thickness, Oxygen

Natural

Preheat

Speed,

Cutting

Natural

Oxygen

Size

Part No. in.

*

Gas

Oxygen

ipm

Oxygen

Gas

**

Cutting

Preheat

30

460064

24 - 26

22

7 - 15

11 - 25

2-3-1/2

2160

190 - 380

285-570

19/64”

5/64”

40

596578

28 - 30

18

11 - 16

18 - 25

2-3-1/2

3470

275 - 400

410-600

“X”

46

50

5470081 35 - 40

12

12 - 17

20 - 26

3

4600

380 - 450

570-675

1/2”

46

60

5470082 45 - 50

7

14 - 18

25 - 30

2-2-1/2

5450

450 - 525

675-790

19/32”

45

70

5490062 50 - 60

6

16 - 24

30 - 40

2-1-1/4

7500

525 - 650

790-975

11/16”

43

* Read from gauge mounted on torch.

**Preheat oxygen flow is given as 50% of natural gas flow for a 1.5 oxygen to 1.0 natural gas ratio. This oxygen/natural gas ratio produces a long

inner cone flame length which is used for most heavy cutting operations.

Nozzle

Gas Pressure, psig

Gas Consumption, cfh

Cleaning Drill Size

Steel

Cutting

Cutting

Preheat

Thickness, Oxygen

Preheat

Speed,

Cutting

Oxygen

Size

Part No. in.

*

Acetylene

Oxygen

ipm

Oxygen

Acetylene

**

Cutting

Preheat

30

08Z78

24 - 26

22

10

20

2-3-1/2

2160

213

170

19/64”

53

40

08Z80

28 - 30

18

10

20

2-3-1/2

3470

272

217

“X”

54

50

08Z82

35 - 40

12

10

20

2-3

4600

330

264

1/2”

3/64”

* Read from gauge mounted on torch.

**Preheat oxygen flow is given as 80% of acetylene flow. This oxygen/acetylene ratio produces an 18 in. acetylene feather which is used for

most heavy cutting operations.

1701 Series Acetylene Nozzles

line valve to the dispenser or back out the air regulator

adjusting screw. Vent the dispenser by opening the pet-

cock on the cover.

IV. MAINTENANCE

To prevent fires do not use common oil or grease

on this equipment. Only use lubricants specifically

indicated in the text and illustrations.

A. GENERAL

Equipment should be inspected at frequent intervals

by a competent operator. Use only standard parts listed

herein. For repairs or replacement other than those

mentioned in these instructions, return the equipment

to ESAB Remanufacturing Center, 411 S. Ebenezer

Road, Florence, SC 29501.

B. CLEANING COMMERCIAL SHUTOFF VALVES

TO OXYGEN STANDARDS

Disassemble the valve. Scrub or immerse the parts in

a hot solution of sodium carbonate or trisodium phos-

phate mixed in the proportions of 1 lb. to 3 gallons of

water. Note that 1 lb. of soda ash or 2-3/4 lb. of sal