© ESAB AB 2011

- 14 -

bp16ea

Torch trigger/Gas test switch - (4)

Operating modes:

Normal trigger (CENTER position) - Setting will be used for most cutting and gouging

operations. The torch switch must be held in by the operator during the entire cutting

operation and then released at the end of cut. Recommended for normal cutting,

expanded metal/grate cutting and gouging.

Trigger lock (DOWN position) - allows the torch switch to be released after triggering

and the cutting arc has been initiated. To extinguish the arc at the end of the cut,

press and release the torch switch again or pull the torch away from the work piece.

Not recommended for expanded metal/grate cutting.

Test mode:

Gas test switch (UP position) - The display will indicate flowing air pressure. The air

regulator should be adjusted to recommended pressure before cutting operations.

Allow air to flow for a few minutes. This should remove any condensation that may

have accumulated during a shutdown period. Be sure to place the switch in normal

trigger or trigger lock position before starting any cutting operations.

Pressure regulator - (5)

Regulates torch air pressure. Rotate clockwise to increase and counterclockwise to

decrease.

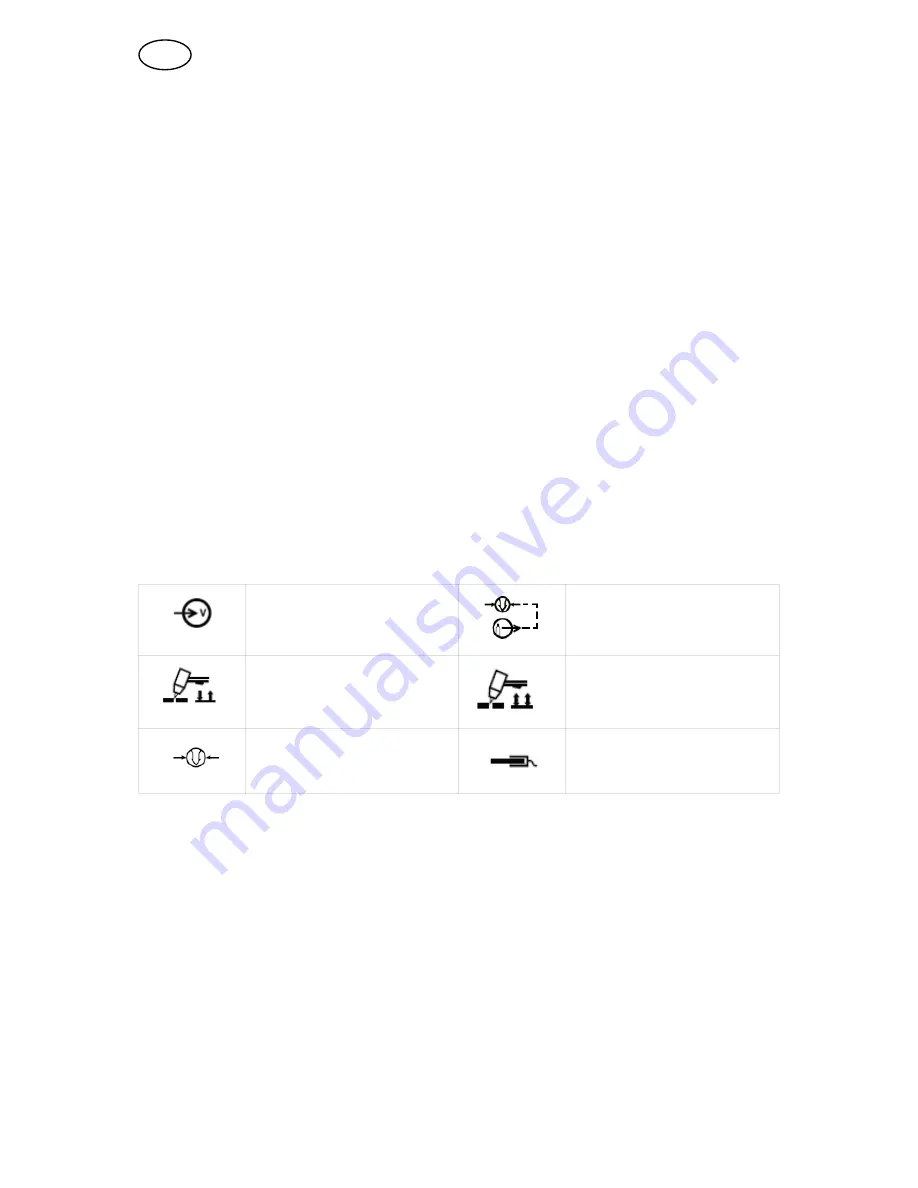

5.2.1

Symbol key

Power (1)

Gas test (4)

Normal trigger (4)

Trigger lock (4)

Air pressure (5)

Return cable

NOTE!

The unit is supplied from the factory with the regulator set to give 5.5 bar (80 psig) to the

torch from a 6.5 bar (95 psig) supply. If the supply pressure to the unit exceeds 6.5 bar (95 psig)up to

the maximum recommended 10.3 bar (150 psig), turn the pressure regulator counterclockwise to

reduce the pressure to the torch to 5.5 bar (80 psig). Follow the gas testing instructions above.

GB