2.0

12

SECTION 2

INTRODuCTION

2.0

INTRODuCTION

2.0 Introduction

2.1 General

The Powercut 1600 is a compact plasma cutting system. As shipped, the system is fully assembled and

ready to cut after being connected to input power and a source of compressed air (350 cfh @ 90 psi / 6.2

bar). The Powercut package uses the heavy-duty PT-38 (manual plasma) torch to deliver cutting power for

selected materials up to 1.50 inch (38.1 mm) thick and severing selected materials up to 1.75 inch (45 mm)

thick

2.2 Scope

The purpose of this manual is to provide qualified repair personnel with technical information which will as

-

sist in troubleshooting and repairing malfunctions.

2.3 Service Manual Format

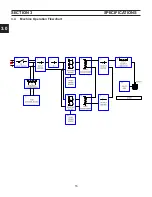

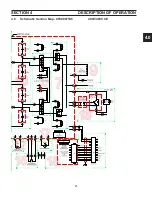

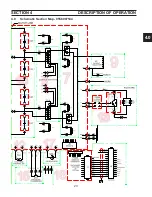

The “machine operation” flow diagram starts the breakdown of the functionally of the PC-1600. Each of the

major components is divided into sections, which are described in the pages that follow. Each section in the

flow chart has a matching section on the main schematic and is applied to the description pages.

Each section starts with the schematic view with description, if the section includes a printed circuit PC

board, it is followed by a PC board schematic, the layout of the board and then the component list for the

board. Some PC boards will also have “mini descriptions” of selected circuits. This information is for trou-

bleshooting purposes only, PC board repair is not recommended.

Summary of Contents for PowerCut 1600

Page 16: ...3 0 16 section 3 SPECIFICATIONS 3 4 Machine Operation Flowchart...

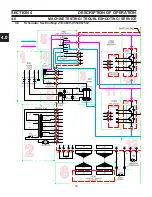

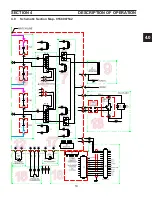

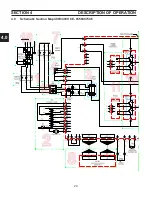

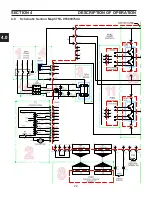

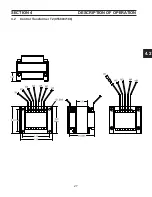

Page 27: ...4 2 27 4 2 Control Transformer T2 0558007188 SECTION 4 DESCRIPTION OF OPERATION...

Page 30: ...4 3 30 4 3 Input Bridge 0558007068 0558007077 SECTION 4 DESCRIPTION OF OPERATION...

Page 35: ...4 6 35 blank...

Page 38: ...4 8 38 4 8 PCB1 Control Board 0558038317 SECTION 4 DESCRIPTION OF OPERATION 4 10 6 8 5 3 11 7...

Page 52: ...4 8 52 4 8 14 PCB1 Layout 0558038317 SECTION 4 DESCRIPTION OF OPERATION...

Page 60: ...4 10 60 4 10 2 Power PC Board Schematic 2 0558038315 SECTION 4 DESCRIPTION OF OPERATION 3 14 8...

Page 67: ...4 10 67 4 10 7 Power Board_PCB2 Control Relays 0558038315 SECTION 4 DESCRIPTION OF OPERATION...

Page 77: ...4 10 77 4 10 16 Buss Supply IGBT SECTION 4 DESCRIPTION OF OPERATION...

Page 91: ...4 11 91 4 11 Power Driver 0558038335 SECTION 4 DESCRIPTION OF OPERATION...

Page 109: ...4 19 109 SECTION 4 DESCRIPTION OF OPERATION 4 19 PT38 Plasma Torch...

Page 110: ...4 19 110 SECTION 4 DESCRIPTION OF OPERATION 4 19 PT38 Plasma Torch...

Page 113: ...5 0 113 5 1 Wiring Diagram 230 460 Volt 0558007543 section 5 WIring diagrams...

Page 114: ...5 0 114 5 1 Wiring Diagram 230 460 Volt 0558007543 section 5 WIring diagrams...

Page 115: ...5 0 115 5 1 Wiring Diagram 230 460 Volt 0558007543 section 5 WIring diagrams...

Page 116: ...5 0 116 section 5 WIring diagrams 5 1 Wiring Diagram 230 460 Volt 0558007543...

Page 117: ...5 0 117 section 5 WIring diagrams 5 1 Wiring Diagram 230 460 Volt 0558007543...

Page 118: ...5 0 118 5 2 Wiring Diagram 400 400V CE 0558007547 section 5 WIring diagrams...

Page 119: ...5 0 119 section 5 WIring diagrams 5 2 Wiring Diagram 400 400V CE 0558007547...

Page 120: ...5 0 120 5 2 Wiring Diagram 400 400V CE 0558007547 section 5 WIring diagrams...

Page 121: ...5 0 121 section 5 WIring diagrams 5 2 Wiring Diagram 400 400V CE 0558007547...

Page 122: ...5 0 122 5 2 Wiring Diagram 400 400V CE 0558007547 section 5 WIring diagrams...

Page 123: ...5 0 123 section 5 WIring diagrams 5 2 Wiring Diagram 400 400V CE 0558007547...

Page 124: ...124 5 3 Wiring Diagram 575V 0558007545 section 5 WIring diagrams...

Page 125: ...125 section 5 WIring diagrams 5 3 Wiring Diagram 575V 0558007545...

Page 126: ...126 5 3 Wiring Diagram 575V 0558007545 section 5 WIring diagrams...

Page 127: ...127 section 5 WIring diagrams 5 3 Wiring Diagram 575V 0558007545...

Page 128: ...128 5 3 Wiring Diagram 575V 0558007545 section 5 WIring diagrams...

Page 129: ...129 section 5 WIring diagrams 5 3 Wiring Diagram 575V 0558007545...

Page 130: ...130 blank...

Page 135: ...6 0 blank 135...

Page 136: ...6 0 136 section 6 replacement parts 6 3 Front 0558007540...

Page 140: ...6 0 140 6 3 Top 0558007540 section 6 replacement parts...

Page 144: ...6 0 144 section 6 replacement parts 6 3 Left Inside2 0558007540...

Page 146: ...6 0 146 section 6 replacement parts 6 3 Rear View 0558007540...

Page 148: ...6 0 148 6 3 Front Rear Isometric Views 0558007540 section 6 replacement parts...

Page 159: ...159 section 7 mechanized conversion 20 Trim all tie wraps and replace the unit s cover...

Page 166: ...10 166 SECTION 9 General information 10 3 Ohm s and Watt s Laws...

Page 171: ...10 171 10 6 Ohm Testing SECTION 9 General information...

Page 172: ...10 172 10 7 Diode Testing SECTION 9 General information...

Page 173: ...10 173 10 8 Ripple SECTION 9 General information...

Page 174: ...10 174 10 9 Voltage Measurement SECTION 9 General information...

Page 178: ...10 178 IGBT Tester Schematic 10 10 1 IGBT Testing SECTION 8 General information...

Page 182: ...182 revision history Original release 11 2008 1...