14

SECTION 3

OPERATION

3.1 OPERATION

ELECTRIC SHOCK can kill.

• Do NOT operate the unit with the cover

removed.

• Do NOT apply power to the unit while hold-

ing or carrying the unit.

• Do NOT touch any torch parts forward of the

torch handle (nozzle, heat shield, electrode,

etc.) with power switch on.

ARC RAYS can burn eyes and skin;

NOISE can damage hearing.

• Wear welding helmet with No. 6 or 7 lens

shade.

• Wear eye, ear, and body protection.

Position the PowerCut-550 at least 10 feet (3

meters) from the cutting area. Sparks and hot

slag from the cutting operation can damage

the unit.

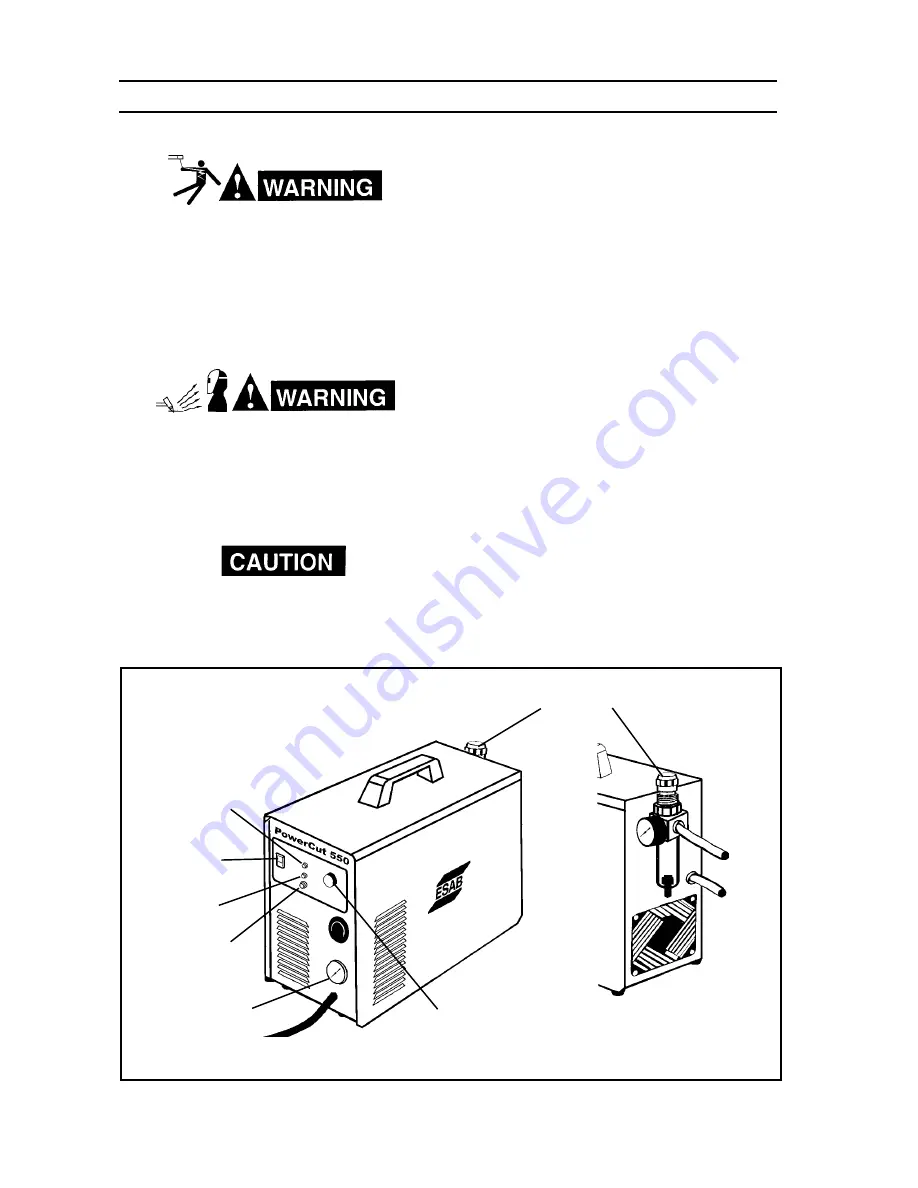

3.2 PowerCut-550 CONTROLS

(FIGURE 3-1)

A.

Power Switch (located on front panel).

When

placed in ON position, the white pilot light will

glow indicating control circuit is energized and

the cooling fan will run.

B.

Output Current Control.

Adjustable from 15

to 35 amperes to suit cutting conditions.

C.

Air Check Push Button Switch.

When ener-

gized, air filter-regulator can be adjusted to

desired pressure (55-65 psig) before cutting

operations. Allow air to flow for a few minutes.

This should remove any condensation that

may have accumulated during shutdown pe-

riod. After setting the pressure, release the

button to its normal position.

Figure 3-1. PowerCut 550 Controls

AIR REGULATOR

CONTROL KNOB

AIR PRESSURE

GAUGE

CURRENT

CONTROL

KNOB

REAR

VIEW

POWER ON-OFF

(I-O) SWITCH &

CIRCUIT BREAKER

AIR CHECK

BUTTON

FAULT LIGHT

AMBER

AIR LIGHT

GREEN