PT-19XL PLASMARC CUTTING TORCH

SECTION 3

INSTALLATION AND OPERATION

Cutting Data PT-19XL W/Air (50 AMPS)

F. When cutting operation is completed, wait a

few minutes before placing the POWER switch

to the OFF position so that the cooling fan has

time to remove the heat from the unit. Then

shut off the primary power at the main discon-

nect switch.

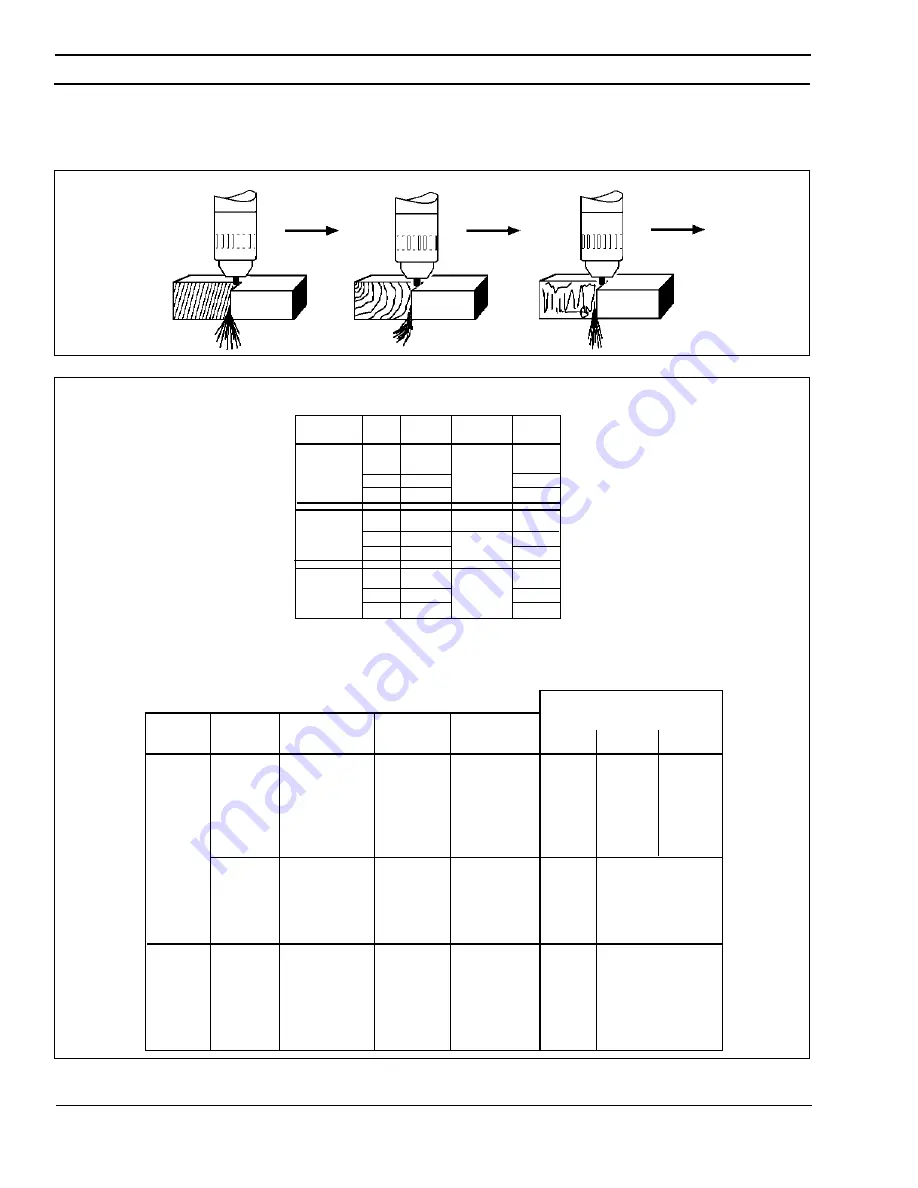

TOO SLOW

TOO FAST

Figure 3-1. Effect of Cutting Speed

CORRECT

Current

Nozzle

150A

34048

250A

34101

Gas Type

& Setting

Air

Low 4

Oxygen

Low 4

Air or

Oxygen

Low 5

Standoff

For Piercing

3/8

3/8

1/2

1/2+

1/2+

3/8

3/8

1/2

1/2+

1/2+

1/2+

1/2+

1/2+

1/2+

Piercing not

Recommended

Standoff

For Cutting

3/8

3/8

3/8

3/8

3/8

3/8

3/8

3/8

3/8

3/8

3/8

3/8

3/8

3/8

3/8

3/8

3/8

Material

Thickness

1/4

3/8

1/2

5/8

3/4

1

1/4

3/8

1/2

5/8

3/4

1/2

5/8

3/4

1

1-1/2

2

Carbon

Steel

130

90

60

50

40

20

130

100

65

55

45

120

100

80

60

30

15

Stainless

Steel

140

75

50

30

20

12

Aluminum

160

115

80

60

40

20

Speed (IPM)

Not

Recommended

No Data Developed

Oxygen Not

Recommended For

Stainless Steel &

Aluminum

Fig 3-2. PT-19XL Cutting Data (Range of Maximum Speeds)

Standoff

1/8 to 3/16

3/16

1/8 to 3/16

1/8

Metal

Low

Carbon

Steel

Stainless

Steel

Aluminum

Thick

1/4

1/8

1/16

1/4

1/8

1/16

1/4

1/8

1/16

Current

65

50

50

65

50

50

65

50

50

IPM

65

120

250

65

80

230

65

130

250

Speed

Note: Pierce at 3/16 to 1/4 inch. Standoffs at the lower end

of the recommended range generally produce less

bevel angle.

Cutting Data PT-19XL W/Air & Oxygen (150 & 250 AMPS)

6