-- 5 --

bu12d04a

1

INTRODUCTION

The ARISTO 2000 is one of the most useful welding systems on the market. To gain

full advantage of your welding equipment, please read this user manual.

You’ll discover many functions that will both simplify and improve your work.

All settings are made from the PUA 1 controller.

You’ll soon notice how easy it is to use. To quickly find topics of special interest in the

user manual, please see the following:

Section 1: Introduction and basics

Sections 2--5: MIG, STICK, TIG and carbon arc gouging, settings directly related to

these welding parameters.

Sections 6--8: The measurements view. memory management and quick settings.

Sections 9--10: Auxiliary functions and the appendix.

See the final page of this publication for a figure illustrating the menu structure.

1.1

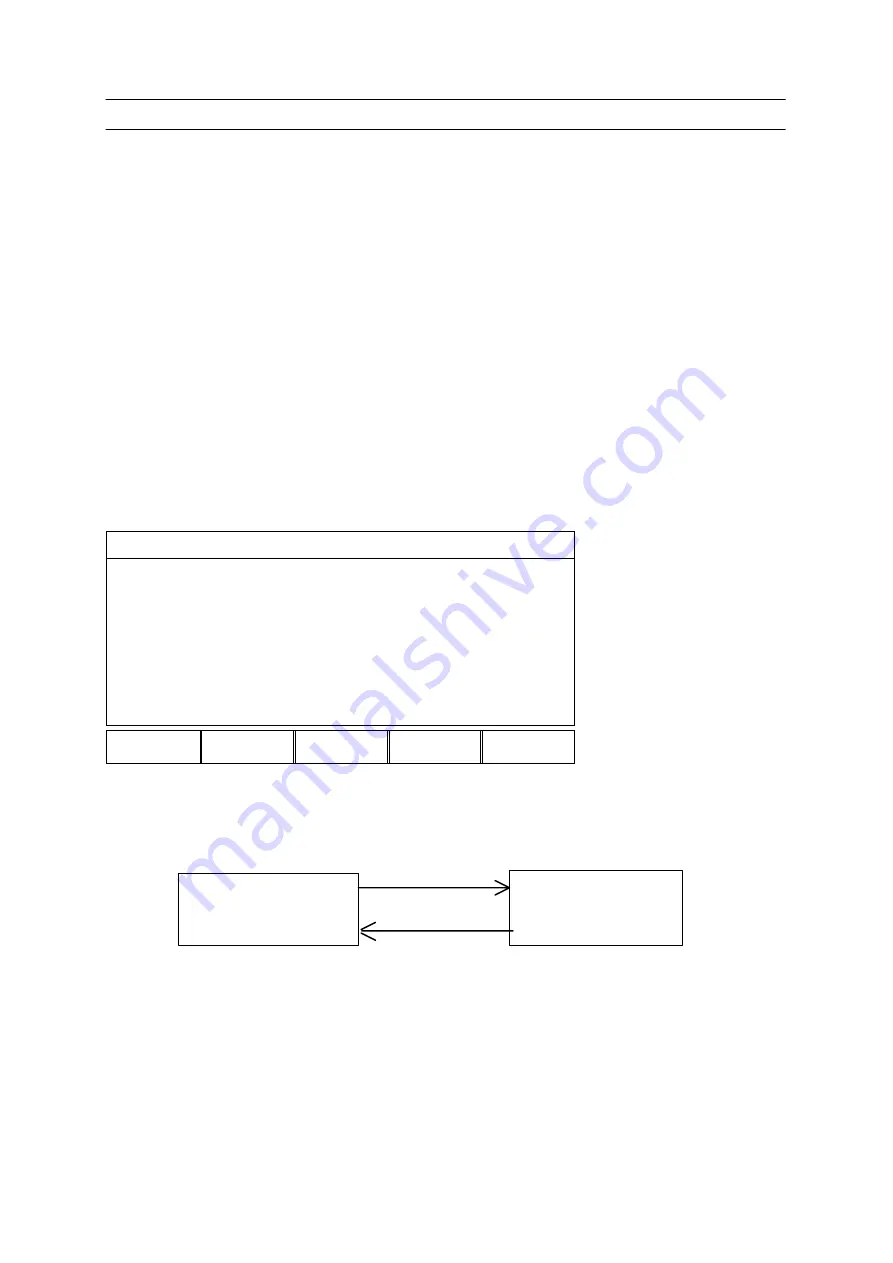

Main menu

ESAB LUD 450

PROCESS:

MIG

METHOD:

DIP/SPRAY

WIRE TYPE:

Metal cored Fe

SHIELDING GAS:

Ar+2O% CO2

WIRE DIAMETER:

0.040” (1.0mm)

AUXILIARY FUNCTIONS

SET

MEASURE

MEMORY

FAST

MODE

ENTER

1.2

Using the Controller

The controller can be said to consist of two units; the

working memory

and the

weld data memory.

WELD DATA

MEMORY

WORKING

MEMORY

DOWN LOAD

SAVED

The working memory is used to store a complete set of welding parameters, which

can then be saved in the weld data memory.

The welding process is always controlled by the contents of the working memory.

This also makes it possible to download a set of welding parameters from the weld

data memory to the working memory.

Note that the working memory always contains the last set of welding parameters

that were used, in other words the working memory is never empty or ”initialized”.