5 OPERATION

0463 691 001

- 26 -

© ESAB AB 2019

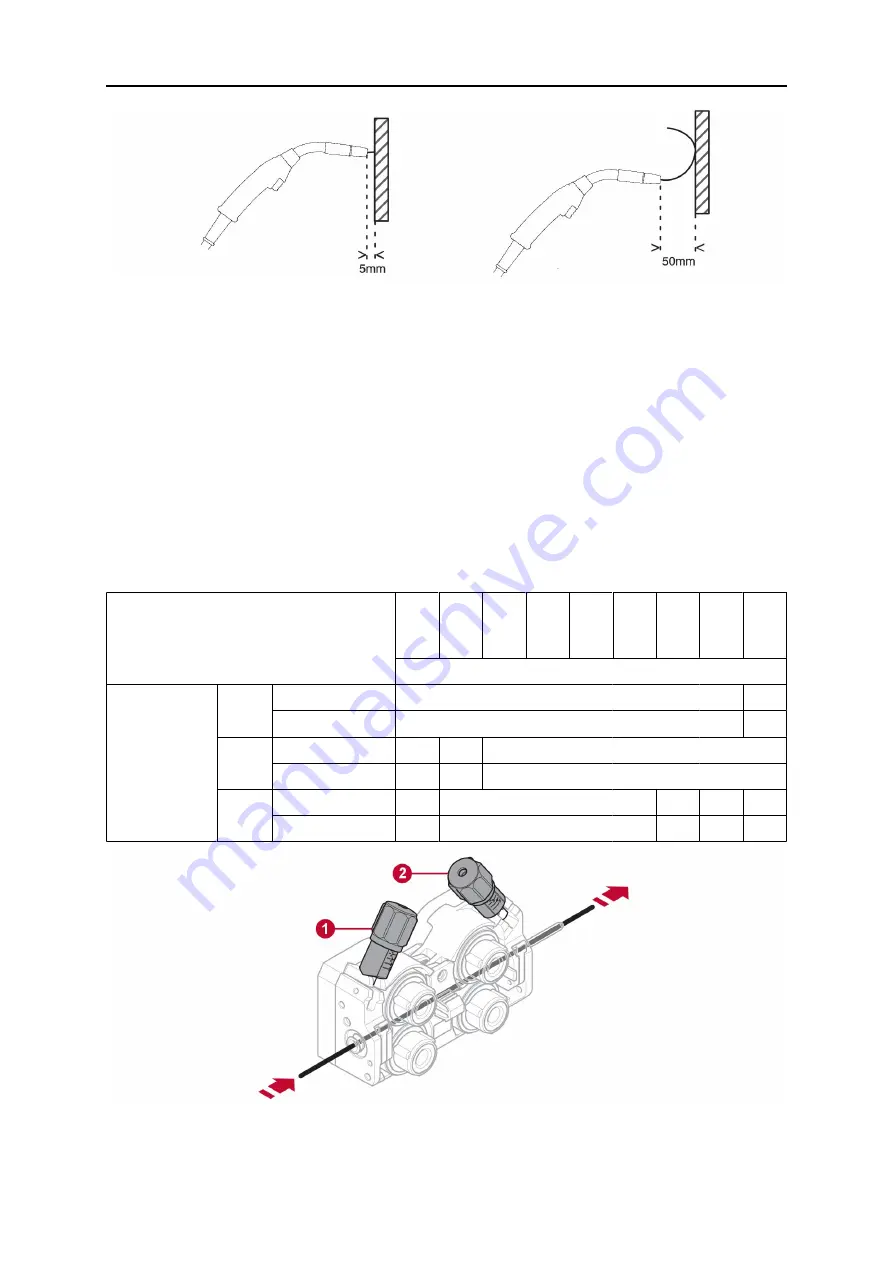

Figure A

Figure B

To check that the feed pressure is set correctly, you can feed out the wire against an

insulated object, e.g. a piece of wood.

When you hold the welding torch approx. 5 mm from the piece of wood (figure A) the feed

rollers should slip.

If you hold the welding torch approx. 50 mm from the piece of wood, the wire should be fed

out and bend (figure B).

The table below serves as a guideline showing approximate roller pressure settings for

standard conditions with correct bobbin brake force. If the torch cables are long, dirty or

worn, the pressure setting may need to be increased. Always check the roller pressure

setting on a case-by-case basis by feeding out the wire against an insulated object as

described above. A table showing approximate settings can also be found on the inside of

the left door of the wire feeder.

Wire diameter (in.)

(mm)

.023

58.3

/ 0.6

.030

58.3

/ 0.8

.040

58.3

/ 1.0

.045

58.3

/ 1.2

.052

58.3

/ 1.4

1/16

58.3

/ 1.6

.070

58.3

/ 1.8

5/64

58.3

/ 2.0

3/32

58.3

/ 2.4

Pressure setting

Wire material

Fe, Ss Tensioner unit 1

58.3 / 2.5

Tensioner unit 2

3-3.5

Cored Tensioner unit 1

2

Tensioner unit 2

2.5-3

Al

Tensioner unit 1

1

Tensioner unit 2

2-3

1.

Tensioner unit 1

2.

Tensioner unit 2