4 OPERATION

0463 697 001

- 12 -

© ESAB AB 2021

4.4

Grinding

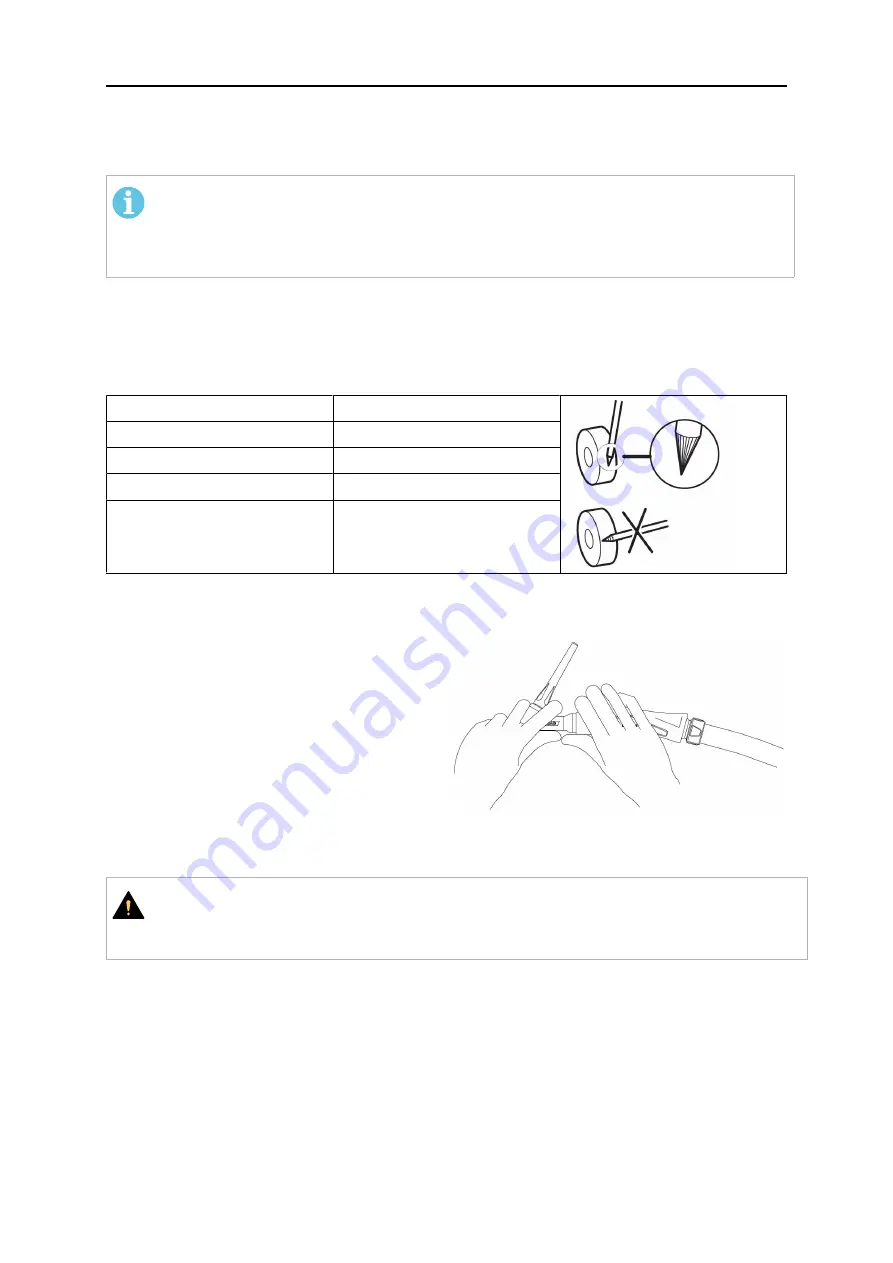

Grind tungsten electrodes according to the following table:

NOTE!

Tungsten electrodes must be grounded lengthways. If they are incorrectly grounded,

the arc may be unstable. When the welding current is increased, the angle must

also be increased.

When welding with alternating current (AC), the electrode end must be gently rounded.

Grinding the electrode is then unnecessary. Light grading of the edge is sufficient. The

electrode forms itself if it is carefully overloaded. If the tip becomes ball shaped while welding

using alternating current, this is a sign that the current is too high for the diameter of

electrode being used.

Welding current

Electrode angle

20 A

30°

20–100 A

30°–90°

100–200 A

90°–120°

over 200 A

120°

4.5

Bending of the flexible torch

The life of the flexible torch is limited. The

maximum bending angle should be

45 degrees.

The life of the torch head can be prolonged by

proper technique.

Always make sure that the torch head is

supported by the thumb when you bend. This

prevents damages at sharp bendings.

4.6

Valve torches

CAUTION!

Do not operate TIG torches with an integrated valve in the torch neck on welding

systems equipped with an ignition and stabilization device.

Summary of Contents for SR-B 17

Page 2: ......

Page 25: ...WEAR PARTS 0463 697 001 25 ESAB AB 2021 ...