Summary of Contents for ETS-LINDGREN MAPS 2112 Series

Page 1: ...Multi Axis Positioning System MAPSTM User Manual 1719784 Rev A May 2020...

Page 2: ......

Page 4: ...4...

Page 8: ...8...

Page 18: ...18...

Page 20: ...20...

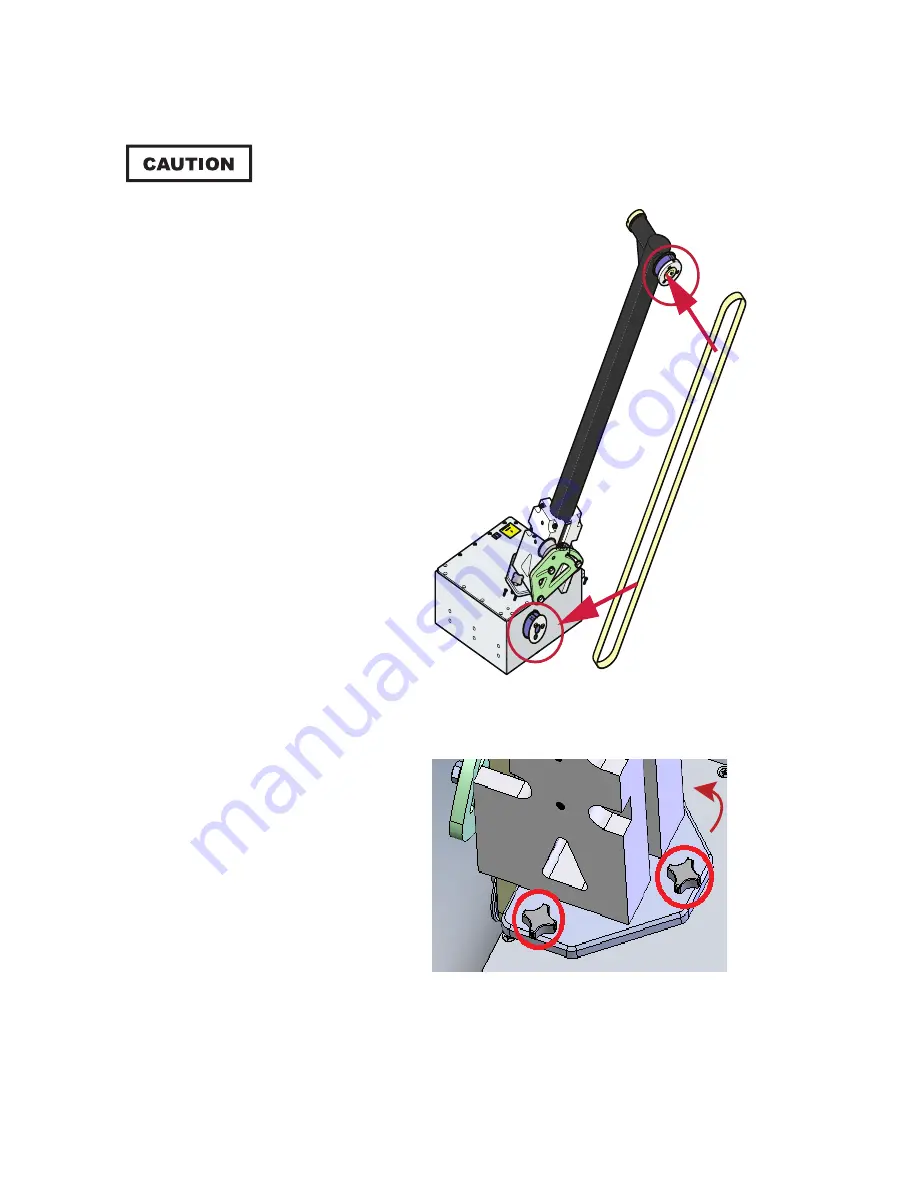

Page 31: ...31 Align laser through the mast mount to the center of the chamber 5 Beam Laser...

Page 34: ...34...

Page 36: ...36...

Page 38: ......