By using the reliable wave distortion

technology to determine if the circuit

is complete, there are no false alarms.

There is no need to adjust or tune the

monitor to a specific user or

installation. The miniscule amount of

electrical current (less than 1 volt coil

cord signal) required to generate the

waveform has never caused reported

skin irritation and is extremely safe

for use in voltage sensitive

applications such as disk drive

manufacturing.

Installation

Remove the Monitor from the carton

and inspect for shipping damage.

Confirm that worksurface RTG

(surface resistance) is 5 x 10

8

or less.

Each unit should include the

following:

1 41116 monitor

1 attached power cord

1 mat monitor cord

1 12102 push & clinch snap

The Workstation Real Time

Continuous Monitor may be mounted

in a convenient position using

pressure-sensitive two piece hook and

loop fastener which is supplied. It is

normally mounted toward the front

edge of a workstation where the LEDs

are easily visible.

Figure 2. Installation of the 41116.

Unit is shown as it is worn by the

operator.

Operation

When the monitor is first plugged into

a properly wired electrical outlet, both

PS-2076

Page 2 of 4

Real Time Continuous Monitor is

drift-free and designed to be

insensitive to the effects of squeezing

or stretching the coil cord.

ADVANTAGES OF WAVE

DISTORTION AND SINGLE-

WIRE TECHNOLOGY

The ESD Systems.com Workstation

Real Time Continuous Monitor allows

the use of any standard, single-wire

wrist strap and coil cord. The

monitor/wrist strap/cord system life-

cycle costs are by far lower than

alternative systems which require

expensive and fragile dual-wire cords

and special wrist straps. Dual-wire

cords are expensive and are the weak

link of the system, the most likely

component to need replacement. Over

a five year period, this can make the

dual-wire system three to five times as

expensive as a system utilizing single-

wire wrist straps and cords.

The dictionary defines constant as

uniform and unchanging, and

continuous as uninterrupted. None-

theless, some dual-wire resistance

monitors utilize a pulsed test current

and do not really provide continuous

monitoring. For example, during each

2.2 second pulse cycle of a leading

“constant” resistive monitor, electrical

current is pulsed for only 0.2 seconds

followed by an unmonitored interval

of 2 seconds. This leaves the

user/wrist strap unmonitored for over

90% of each cycle. Damaging static

charges can easily occur in the portion

of the time in between the pulses. The

off period of 2 seconds equals 2

billion nanoseconds, and “it takes only

about 25 volts applied for 100

nanoseconds to blow most memories

or microprocessors”.* The dual-wire

system does not reliably meet all

industry specifications, as the cords do

not meet the EOS/ESD Association

guidelines for the 1 to 5 pound

“breakaway force” requirement for

operator safety.

red LEDs will light and the alarm will

sound.† The alarm will be sounding at

this time since no wrist strap wearer

or work surface is hooked up.

With a wrist strap on the wrist and the

coil cord attached to the band, plug

the banana plug of the wrist strap

ground into the banana jack marked

“User”. This will cause the operator

green LED to light if the wrist strap is

functioning properly.

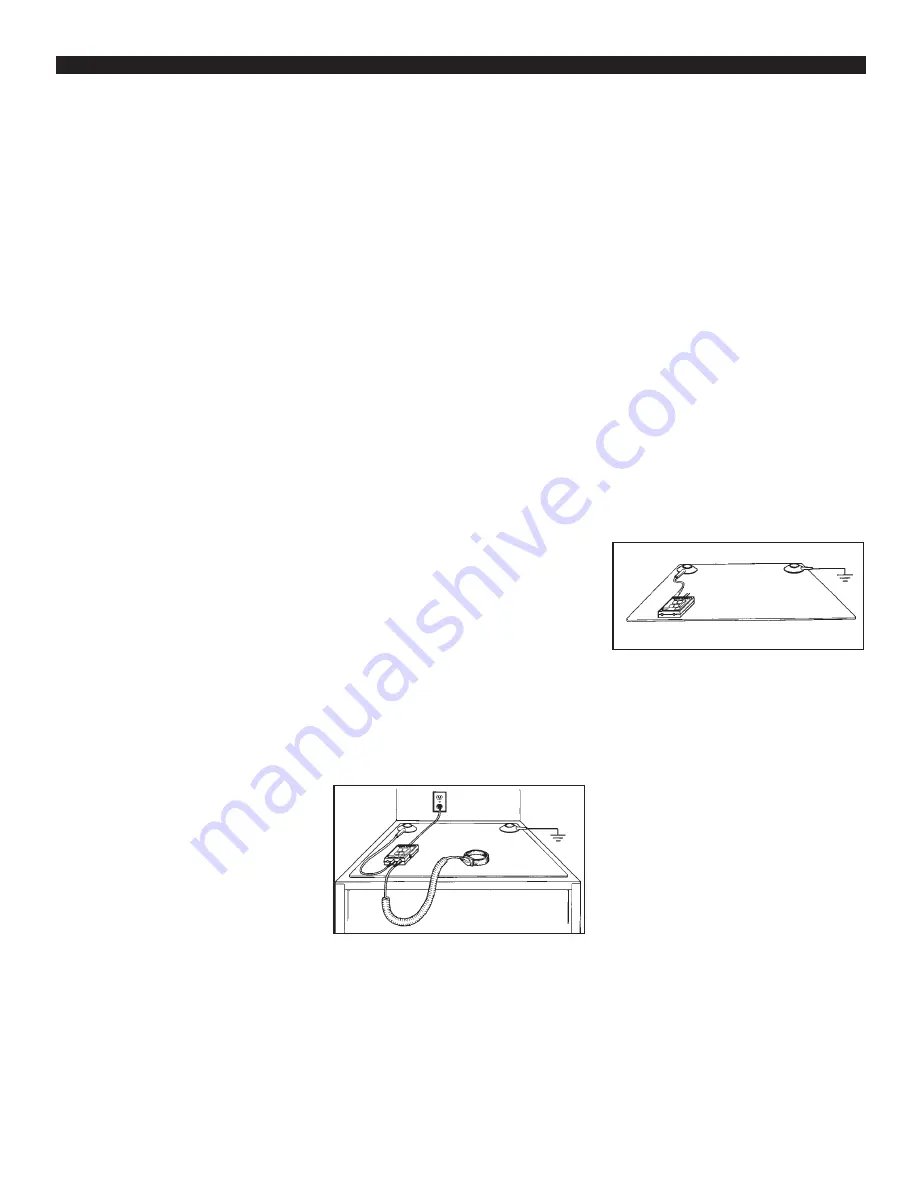

Now connect a mat ground cord to the

work surface. (NOTE: The work

surface should be already grounded

with another mat ground cord.) Plug

the banana plug of the mat ground

cord (ESD Systems.com Item #13258)

into the banana jack marked “Work

Surface” (See Figure 3). This will

cause the “Work Surface” green LED

to light if the work surface is properly

grounded.

Figure 3. Installing ground cords on

the work surface.

The user may disconnect the coil cord

from the wrist band and leave the

workstation by first touching the

Standby Snap. This deactivates the

alarm for six seconds and allows the

operator to attach the coil cord to the

Standby Snap. Using this procedure,

the alarm will not sound, which

otherwise could be interpreted as a

problem. Note that if the coil cord is

removed from the wrist band and not

placed on the Standby Snap within six

seconds, the alarm will sound.

†The Workstation Real Time Continuous Monitor

takes 6 seconds to activate its alarm circuitry

when it is first plugged in.

*1981 article by Donald E. Frank - Electrical

Overstress Electronic Discharge Symposium

Proceedings

© 2006 DESCO INDUSTRIES INC.

Employee Owned

432 NORTHBORO ROAD CENTRAL • MARLBORO, MA 01752 • PHONE (508) 485-7390 • FAX (508) 480-0257 • http://www.esdsystems.com