Dual Operator Workstation Continuous Monitor with

Satellites - Operation, Installation and Maintenance

Tech Brief

PS-2119

April 2007 Page 1 of 4

Description

Leading companies use continuous

monitors as a cost effective component

in satisfying the paragraph 6.1.3

Compliance Verification Plan

requirements of ANSI/ESD S20.20. The

ESD Systems.com Dual Operator

Continuous Monitor with Satellites

continuously monitors the grounding

integrity of two operators, and two ESD

worksurfaces' path to ground. The

monitor will provide instantaneous

notification of static control equipment

failures, and eliminates the need of

costly and difficult to supervise wrist

strap logging record keeping. This unit

is highly cost effective as it is designed

to monitor any conventional single-wire

wrist strap and ground cord system.

Per ESD Handbook TR 20.20 paragraph

5.3.2.4.4 Test Frequency, "Because wrist

straps have a finite life, it is important

to develop a test frequency that will

guarantee integrity of the system.

Typical test programs recommend that

wrist straps that are used daily should

be tested daily. However, if the products

that are being produced are of such

value that knowledge of a continuous,

reliable ground is needed, then

continuous monitoring should be

considered or even required."

The Dual Operator Continuous Monitor

with Satellites is available in two

models.

The Dual Operator Continuous Monitor

with Satellites is an impedance sensing

device designed to monitor body types

from a 5th percentile female to a 95th

percentile male. This range covers a 5

foot tall 90 pound person to a 6 foot 5

inch 250 pound person in any produc-

tion environment.* The 41222 is

powered by a 120 VAC, 60/50 Hz, plug-

in transformer which also provides

connection to ground.

No user adjustment required:

The

Continuous Monitor is drift-free and

designed to be insensitive to the effects

of squeezing or stretching the coil cord.

It requires no user adjustment.

The Dual Operator Workstation

Continuous Monitor is a real time

instrument that ensures that critical ESD

control components in a sensitive area

are effectively grounded. It

independently monitors the operator and

the work surface. The instant an

operator's wrist strap or cord fails, the

monitor will issue audible and visual

alarms alerting the user of the problem.

In the same manner, the unit also

confirms that a path to ground of less

than 10 megohms (1 x 10E7 ohms)

exists from the ESD protective work

surface(s).

ADVANTAGES OF CONTINUOUS

MONITORING OVER PERIODIC

TESTING

Many customers are eliminating

periodic touch testing of wrist straps

and are utilizing continuous monitoring

to better ensure that their products were

manufactured in an ESD protected

environment. Full time continuous

monitoring is superior to periodic or

pulsed testing, and can save a

significant amount of money in testing

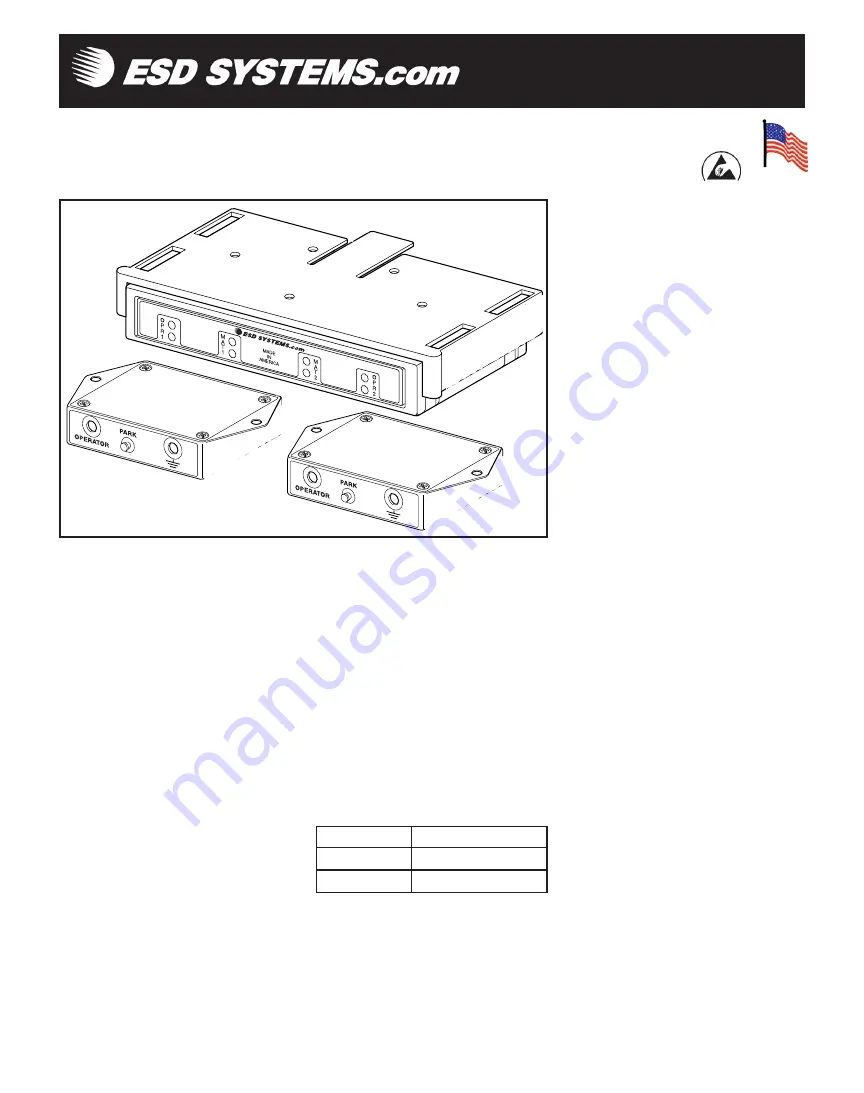

Figure 1. ESD Systems.com Dual Operator Continuous Monitor with Satellites

Position Satellite Remote Monitor where most convenient for operator.

Position Monitor Control Unit for optimal supervisor visibility.

ESD Systems.com • 432 Northboro Road Central • Marlboro, MA 01752 • (508) 485-7390 • Fax (508) 480-0257 • Web Site: ESDSystems.com

© 2007 DESCO INDUSTRIES INC.

Employee Owned

Made in America

*NASA Publication 1024-Anthropomorphic

Source Book Volume 1: “Anthropometry for

Designers”

** Per ANSI/ESD S20.20 paragraph 6.0.3.

Tailoring "This document, or portions thereof,

may not apply to all applications. Tailoring is

accomplished by evaluating the applicability of

each requirement for the specific application.

Upon completion of the evaluation, requirements

may be added, modified or deleted. Tailoring

decisions, including rationale, shall be

documented in the ESD Control Program Plan."

Model

Voltage AC

41222

120 Volt

41223

220 Volt