TB-5545 Page 1 of 4

Revision May 2009

© 2009 DESCO INDUSTRIES INC.

Employee Owned

ESD Systems.com • 432 Northboro Road Central • Marlboro, MA 01752 • (508) 485-7390 • Fax (508) 480-0257 • Website:

Ground Gard 3 Plus

Operation, Installation, and Maintenance

TECHNICAL BULLETIN TB-5545

Made in America

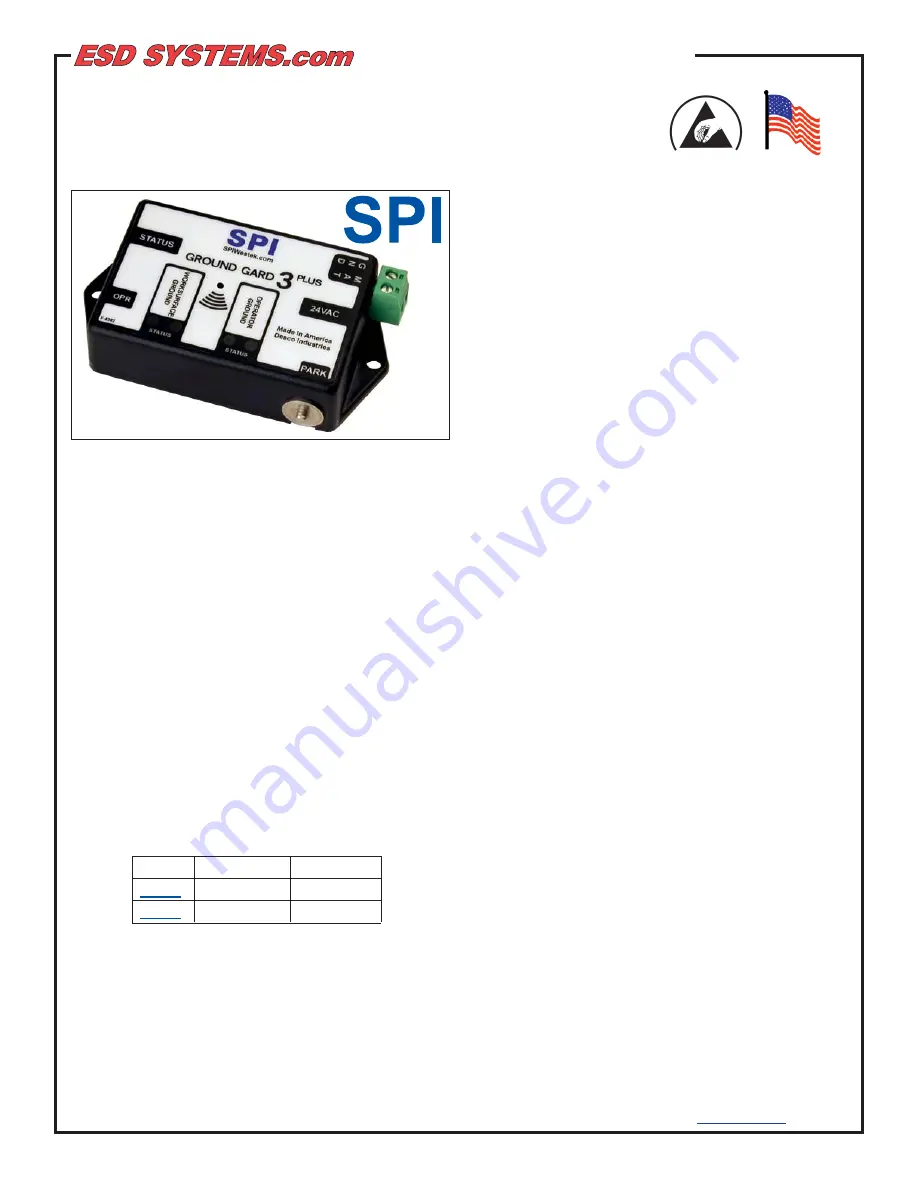

Figure 1. SPI Ground Gard 3 Plus

Description

Leading companies use continuous monitors as a cost

effective component in satisfying the paragraph 6.1.3

Compliance Verifi cation Plan requirements of ANSI/

ESD S20.20. The SPI Ground Gard 3 Plus continuously

monitors the integrity of one operator and one ESD work-

surface. This monitor will provide virtually instantaneous

notifi cation of static control equipment failures, eliminat-

ing the need of periodic testing and costly record keep-

ing. This unit is highly cost effective as it is designed

to monitor any conventional single wire wrist strap and

ground cord system. Its small package and mounting

tabs with holes make it highly suitable to install on most

any equipment or work bench surface. In addition, op-

tional mounting is available using the provided adhesive-

backed Velcro® strips. Using either mounting method

makes the Ground Gard 3 Plus suitable for most any

machinery or workbench even in hard to reach locations.

The SPI Ground Gard 3 Plus is available in two models:

The Ground Gard 3 Plus is a real time instrument that

ensures that the operator and ESD worksurface in a

sensitive area is effectively grounded. The instant an

operator’s wrist strap or cord fails, the monitor will issue

audible and visual (LEDs) alarms alerting the user and

supervisor of the problem.

The Parking Snap provides a means for the operator to

disconnect the wrist strap cord when normally leaving

the work area without the audible alarm sounding. It also

provides a means of wrist strap cord storage.

ADVANTAGES OF CONTINUOUS MONITORING

OVER PERIODIC TESTING

Many customers are eliminating periodic testing and

are utilizing continuous monitoring to better ensure that

their products were manufactured in an ESD protected

environment. Full time continuous monitoring is superior

to periodic or pulsed testing, and can save a signifi cant

amount of money in testing costs and rejected product.

Periodic testing detects failures after ESD susceptible

products have been manufactured. The costs of dealing

with the resulting catastrophic or latent defects can be

considerable. Ground Gard 3 Plus Monitors eliminate

the need for users to test wrist straps and log the results;

by their function, these monitors satisfy the ISO 9000

and ANSI/ESD S20.20 test logging. ANSI/ESD S20.20

Paragraph 6.2.2.2 Personnel Grounding Guidance states

“A log should be maintained which verifi es that personnel

have tested their personal grounding devices.” Per ESD-

S1.1 Paragraph 6.1.3 “Daily (wrist strap system) testing

may be omitted if constant monitoring is used.”

WAVE DISTORTION DETECTION TECHNOLOGY

PROVIDES TRUE 100% CONTINUOUS MONITORING

From all the technical alternatives available, SPI has

chosen wave distortion technology for many of its Con-

tinuous Monitor product offerings. Wave distortion cir-

cuitry monitors current/voltage phase shifts and provides

true 100% continuous monitoring. Electrical current will

lead voltage at various points due to the combinations

of resistance and capacitive reactance. By monitoring

these “distortions” or phase shifts, the wave distortion

Ground Gard 3 Plus will reliably determine if the circuit is

complete.

Wave distortion technology can be referred to “vector

impedance monitoring”. This description is valid as the

wave distortion technology measures the impedance at

the monitored banana jack and looks for changes in ei-

ther the capacitance or resistance of the circuit which in-

cludes the wrist strap and its wearer. It uses fi ltering and

time domain sampling to fi lter out false signals caused by

voltage offsets, 60 Hz fi elds and other electro-magnetic

and electrostatic interference.

Model Voltage AC Calibration