Type / No.

Rev.

Date

Page

Total pages

EW082.695_en

5

02 August 2010

10

28

EsiWelma

s.r.l.

3.2

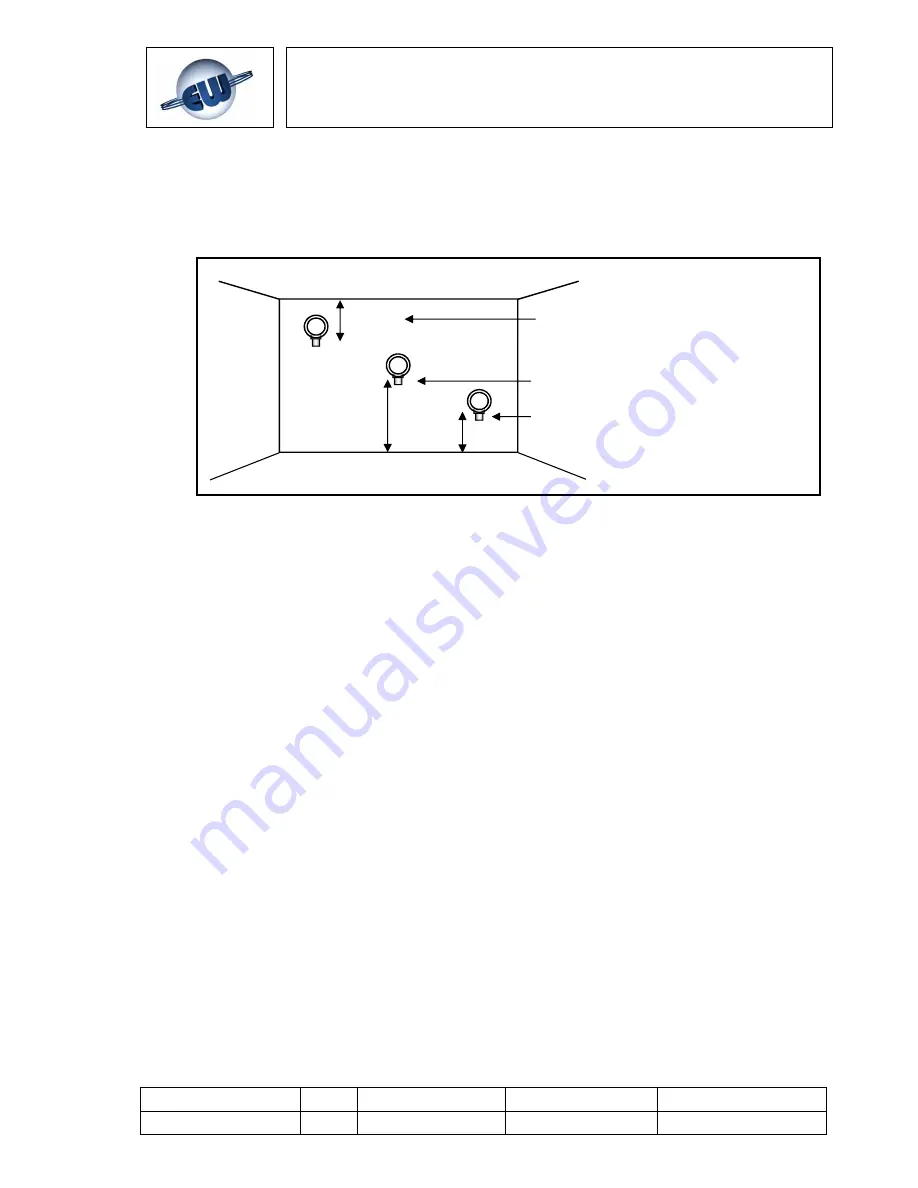

Types of detector installation for correct monitoring

The detectors must be wall-mounted at whatever height is appropriate for the type of gas to

be detected (Fig. 3.4).

Fig. 3.4 – Possible detector positions

Use the information below to correctly position the detectors:

•

20 cm from the floor to detect gases heavier than air (LPG or Gasoline Vapours)

•

20 cm from the ceiling to detect gases lighter than air (Methane)

•

midway between floor and ceiling (1.5 - 2 m) to detect gases as heavy as air (CO)

The TUS40-20 termination kit comes with a 3 m coiled cable so it can operate correctly

even at a considerable height and distance from the sensor.

The connection cable must not be stretched to its full length when it is plugged in to

make sure it does not disconnect from the junction card.

Do not use extension cords on the cables and do not extend the cables themselves by

cutting and joining as this may adversely affect the proper operation and safety of the

device.

To guarantee correct gas detection, in addition to the instructions above, the positions of the

detectors must take into consideration the following specific installation guidelines:

The detector must be mounted:

•

where accidental gas leakages are possible

•

at least 1.5 metres from heat sources

•

not in spaces where ventilation is poor and where gas pockets may form

•

at least 1.5 metres from vent holes

•

away from hindrances to natural gas flow

•

in environments with a temperature range of -20°C to 50°C and relative humidity below

90% (non-condensing).

20 cm

from the ceiling

20 cm from

the floor

1,5-2 m

from the

floor

URG40.. (Methane)

URO40.. (CO)

URP40.. (LPG) URB40.. (Gasoline vapours)