17

TROUBLESHOOTING (CONTINUED)

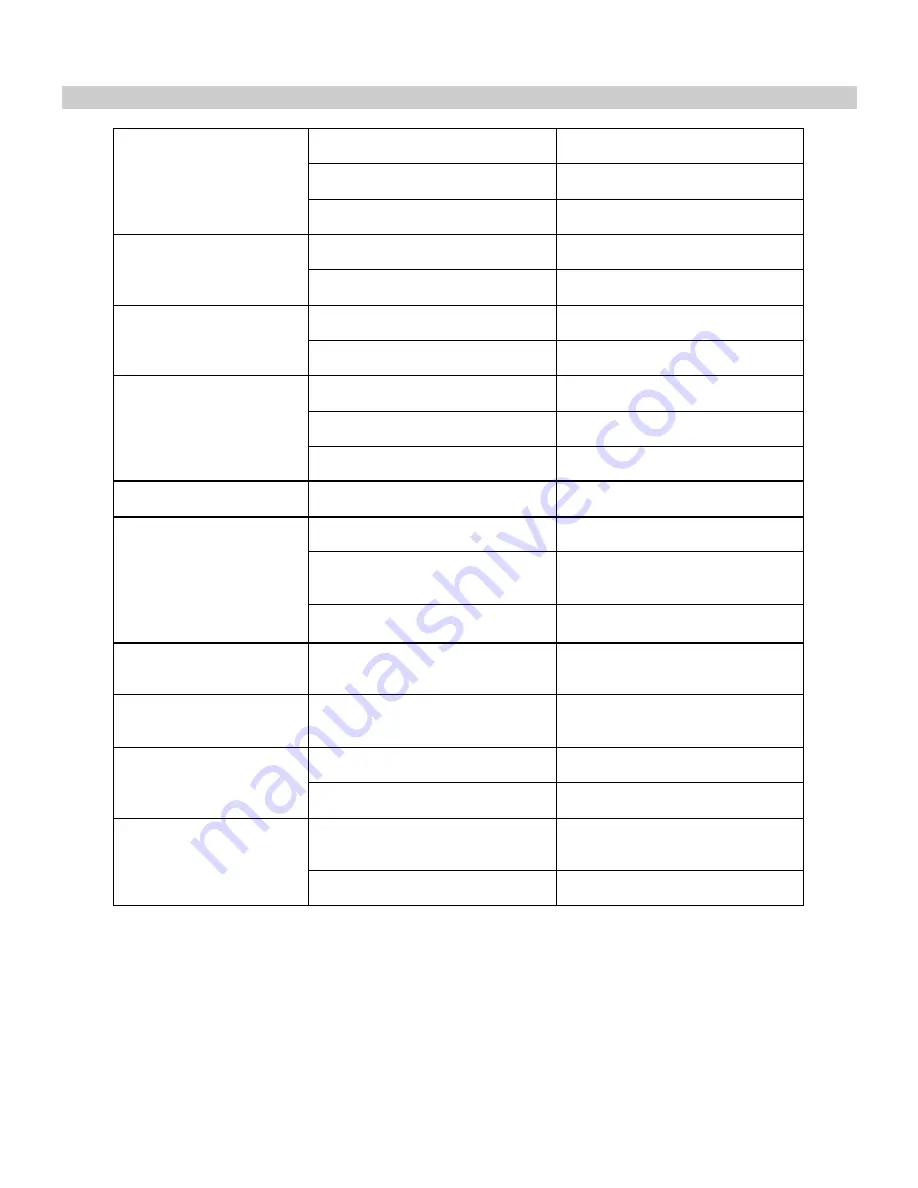

1) Burner orifice is clogged.

1) Clean burner orifice or replace

burner orifice.

2) Burner orifice diameter is too

small.

2) Replace burner orifice.

Burner does not light after

pilot is lit.

3) Inlet gas pressure is too low.

3) Contact local Gas Company.

1) Manifold pressure is too low.

1) Contact local Gas Company.

Delayed ignition of burner.

2) Burner or pilot orifice is clogged. 2) Clean burner or pilot orifice or

replace it.

1) Burner orifice is clogged or

damaged.

1) Clean burner orifice or replace it.

Burner backfiring during

combustion.

2) Gas regulator defective.

2) Replace gas regulator.

1) Inlet pipe is blocked.

1) Remove the blockage.

2) Incorrect connections of pipes.

1) Connect pipes according to

installation instructions.

Yellow flame during burner

combustion.

3) Gas regulator defective

1) Replace gas regulator.

Slight smoke or odor during

initial operation.

1) Residues from manufacturing

processes.

1) Problem will stop after a while of

operation.

1) Turning control knob to HI

position when burner is cold.

1) Turn control knob to LO position

and let warm up for a minute.

2) Air in gas line.

2) Operate burner until air is

removed from line. Have gas line

checked by local Gas Company.

Heater produces a

whistling noise when

burner is lit.

3) Dirty or partially clogged burner

orifice.

3) Clean burner orifice or replace it.

Heater produces a

clicking/ticking noise just

after burner is lit or shut off.

1) Metal expanding while heating or

contracting while cooling.

1) This is common with most

heaters. If noise is excessive,

contact qualified service person.

Heater produces unwanted

odors.

1) Gas leak (see WARNING

statement below).

1) Locate and correct all leaks (see

Checking Gas Connections, page

12)

1) Low line pressure.

1) Contact local Gas Company.

Heater shuts off in use.

2) Pilot is partially clogged.

2) Clean pilot.

1) Gas leak. See WARNING

statement below.

1) Locate and correct all leaks (see

Checking Gas Connections, page

12)

Gas odor even when

control knob is in OFF

position.

2) Control valve defective.

2) Replace control valve.

Summary of Contents for DVEL 12

Page 13: ...12 OPERATION CONTINUED Pilot Burner...

Page 14: ...13 POUR COUPER L ADMISION DE GAZ DE L APPAREIL Veilleuse ALLUMAGE...

Page 20: ...19 Model DVEL 8 19...

Page 21: ...Model DVEL 12 20...

Page 22: ...Model DVEL 20 21...