13

Kongsberg XN / iPC 2.0

118

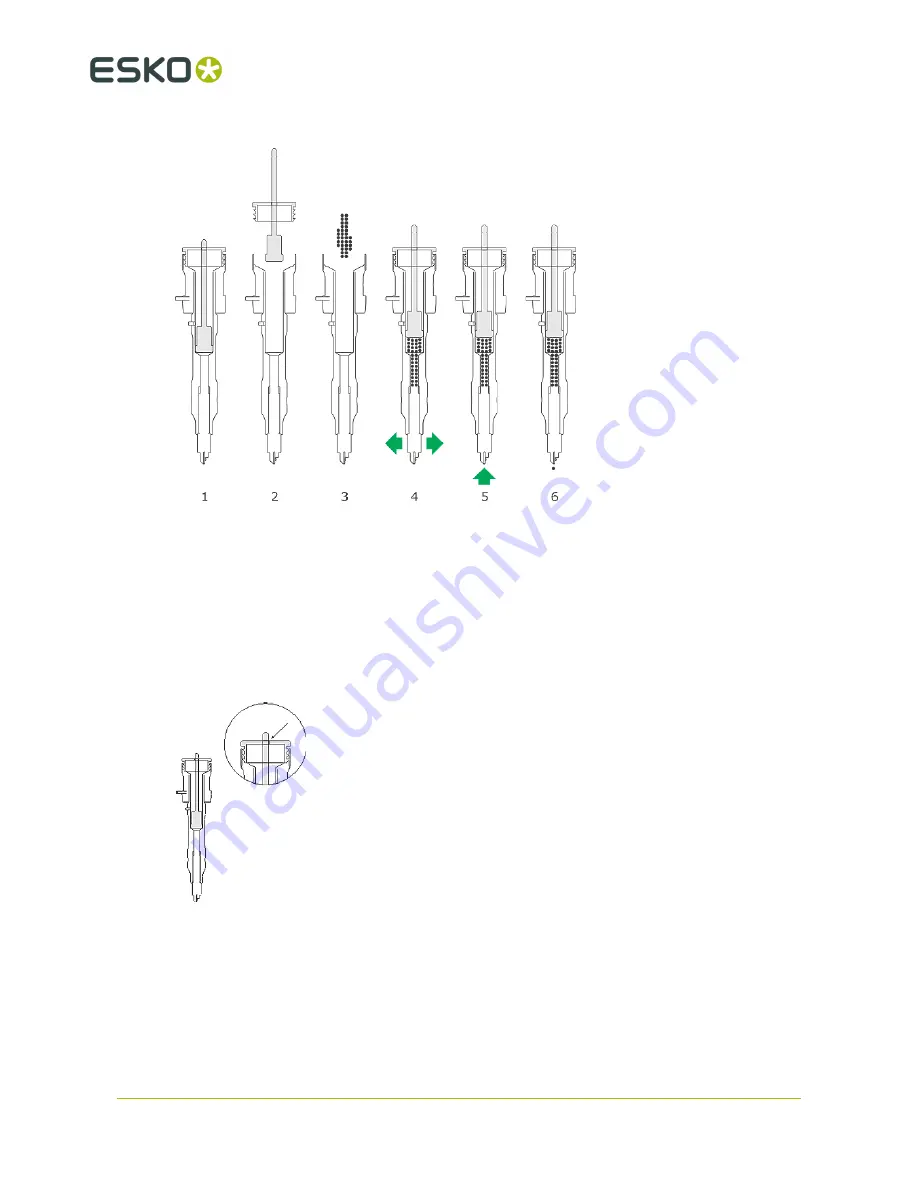

Braille Tool, how to add spheres

1.

Keep the tool in upright position during this process.

2.

Remove the cap and the plunger.

3.

Pour spheres into the tool.

4.

Insert the plunger and the cap. Shake the tool lightly.

5.

Push the dispensing mechanism up.

6.

One sphere should be pushed out from the tool

Plunger

The tool is equipped with a plunger that serves two

purposes:

1.

To force the spheres into the internal funnel.

2.

Indicate the number of spheres remaining in

the tool. If the groove is no longer visible it

means that there is a limited number of spheres

left in the tool.