Model D50 service manual, SMD50l-ac Page 5

eskridge, inc. olathe, KS. 913-782-1238 www.eskridgeinc.com

unit Disassembly Procedure

There are two types of model D50 units: single planetaries with-

out a primary carrier and double planetaries with a primary planet

carrier. The differences in disassembling single stage and double

stage gearboxs are clearly defined throughout this manual.

All parts should be inspected as they are removed from unit.

1)

Scribe across base

(1)

, ring gear

(8)

and cover/ bail assembly

(3)

joints on outside of gearbox to assure proper orientation

of oil fill and drain plugs, motor mounting, etc., as the unit is

reassembled.

2)

Remove hydraulic motor

(15)

from auger drive. Drain oil.

3)

Remove the twelve 7/16 x 4-1/2” socket head cap screws

(12a)

and 7/16 lockwashers

(12b)

, which retain cover/bail

assembly

(3)

and ring gear

(8)

to base

(1)

.

4)

Lift cover / bail assembly

(3)

off of unit.

Single stage: Remove input gear

(4)

, input thrust washer

(7a, 7b)

carrier assembly

(7)

and ring gear

(8)

.

Double Stage:Remove input gear

(4)

, input thrust washer

(9a)

primary carrier assembly

(5).

Remove

secondary sun

(6)

thrust washer

(9b)

and

secondary carrier

(7)

.

5)

The gearing is now disassembled and area(s) requiring re-

pair or service should be identified by thorough inspection

of the parts after they have been washed in solvent. Rotate

planet gears to check for any abnormal noises or roughness

in the primary planet bearings. At the same time, inspect

planet gears for any damage or worn teeth. Replace carrier

assembly if any problems are found in the carrier assembly.

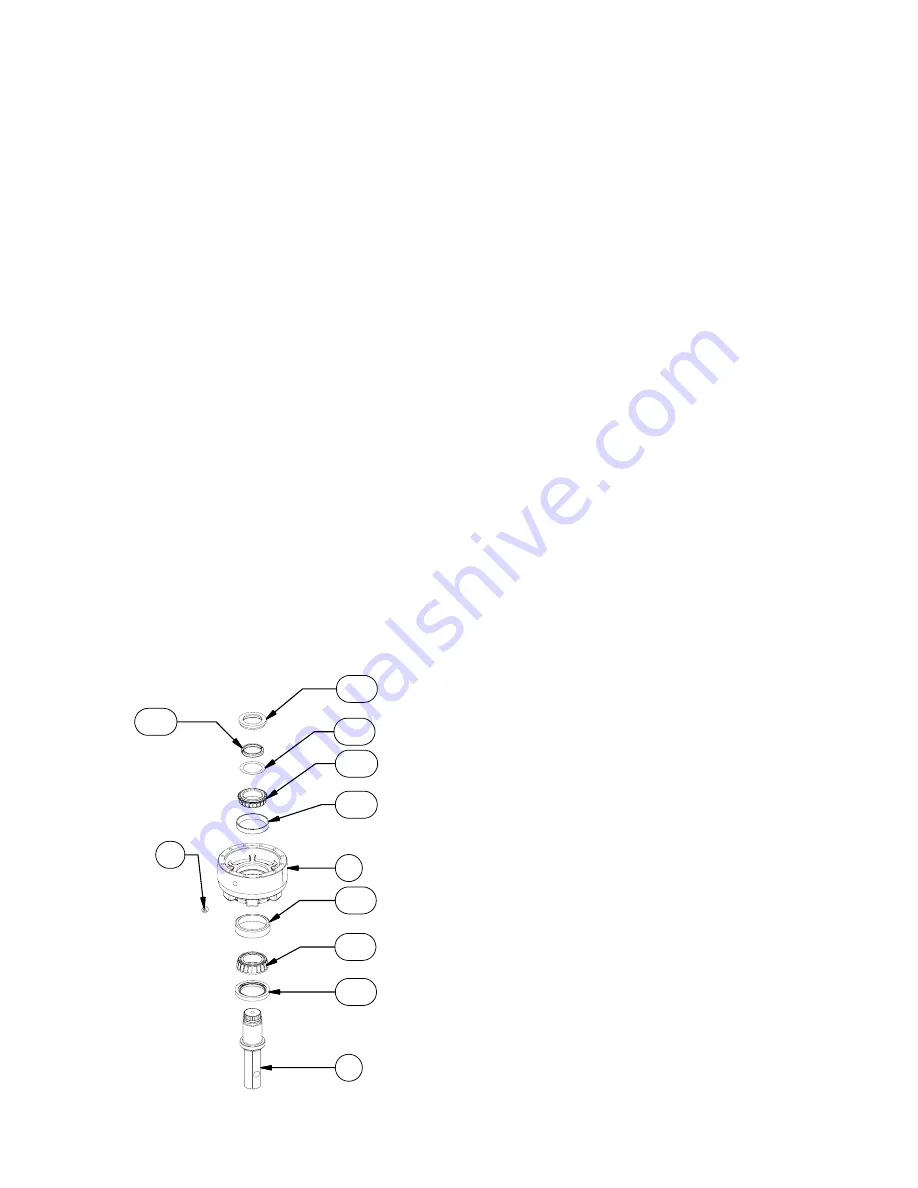

base Subassembly

Disassembly

1)

Place unit on a press table with the output shaft

(2)

protruding

downward through a hole in the table; unit should be support-

ed only by the base

(1)

. The only thing retaining output shaft

(2)

is the locking ring

(14b)

and split ring segments

(14c)

.

Remove the locking ring

(14b)

by prying upward, split ring

segments

(14c)

and shims

(14a).

cauTion: The load-n-lock assembly is no longer retaining

output shaft. Take precautions if the unit is moved as the shaft

may fall out.

2)

With output shaft down through centerhole in press table and

unit supported by base, press shaft out by applying press

load to top end of shaft

(internal end)

until it passes through

inner shaft bearing

(11c)

. Outer shaft bearing

(11a)

and seal

(10b)

will come out of unit attached to shaft.

3) Inspect inner and outer bearing cups

(11b & 11D)

. If cups are

damaged remove and replace both bearing cups and cones.

cauTion: care should be taken not to injure feet or damage

output shaft during this procedure.

4)

If outer bearing cone

(11a)

needs to be replaced, it will need

to be pressed off of output shaft. Also inspect inner bearing

cone

(11c)

. If any one bearing component needs replaced

replace the both the cup and cone as a set.

noTe: When installing or removing bearings, press only on

inner race of bearing cone. Do noT press on outer roller cage

of bearing or it will damage bearing.

5)

Clean all foreign material from magnetic oil plug

(13)

located

on bottom of base

(1)

. Add a small amount of pipe thread

compound to pipe plug before installing it back into base.

unit reassembly

1)

Start with base

(1)

. Turn base upside down and position

on press table. Base should be pointing upward with outer

bearing cup

(11b)

exposed. Apply a layer of lithium bearing

grease to bearing cup surface.

2)

Invert output shaft

(2, load-n-lock retainer groove end

down)

and carefully lower into base

(1)

until the shaft’s out-

er bearing cone

(11a)

is seated against outer bearing cup

(11b)

.

3)

Press shaft seal

(10b)

into base until it is flush with bottom of

pilot diameter. Use a press fixture, if possible, to avoid distort-

ing seal. If press fixture is not available, a hammer and flat-

ended drift may be used by tapping outer edge of seal lightly

and alternating sides.

4)

Stand base assembly upright on output shaft.

cauTion: The only thing holding output shaft and base to-

gether at this point is the tightness in fit of the shaft seal. Se-

curely and cautiously turn unit upright, not allowing base and

shaft to separate.

5)

While holding output shaft

(2)

with one hand, rotate base

(1)

to be certain it turns freely and smoothly. The slight resistance

felt, if any, is due to shaft seal load (drag) on output shaft.

6)

Apply a layer of lithium bearing grease to inner bearing cup

(11D)

surface.

7)

Install inner bearing cone

(11c, small end down)

over inter-

1

2

10B

11A

11B

11C

11D

14A

14B

14C

13