Engineering Installation

Installation site

A. Should be capable of providing sufficient installation and maintenance space.

B. Should be no barrier in the inlet and outlet where would avoid the strong wind.

C. Should be dry and well ventilated.

D. Should have even supporter and strong enough to bear the weight of the machine, where the machine

can be installed horizontally, creating no extra noise and vibration.

E. Should be where the neighbor can’t be disturbed by running noise and discharge air.

F. Should be where no flammable air leakage.

G. Should have easy access for piping and electrical connection.

Attention

1.Cautions for installation

Don’t install the system at the following places, which may cause system failure (please consult our service

team if necessary).

A. Places with mineral oil like cutting machine oil

B. Places with salty air

C. Places with corrosive gas, such as sulfur.

D. Places with fluctuant power supply and voltage

E. Vehicle or cabin

F. Places like kitchen where full of oil ,Places with strong electromagnetic waves

G. Places with flammable gas and materials

H. Places with acidic or alkaline gas

I. Other special places

2.Attention before installation

A. Choose the correct transportation way.

B. Keep the original packing during transportation.

C. If the machine is installed on the metal base of the construction, the electrical insulation must be done

well and strictly

according to the technical standards of electrical equipment.

3.Installation attention

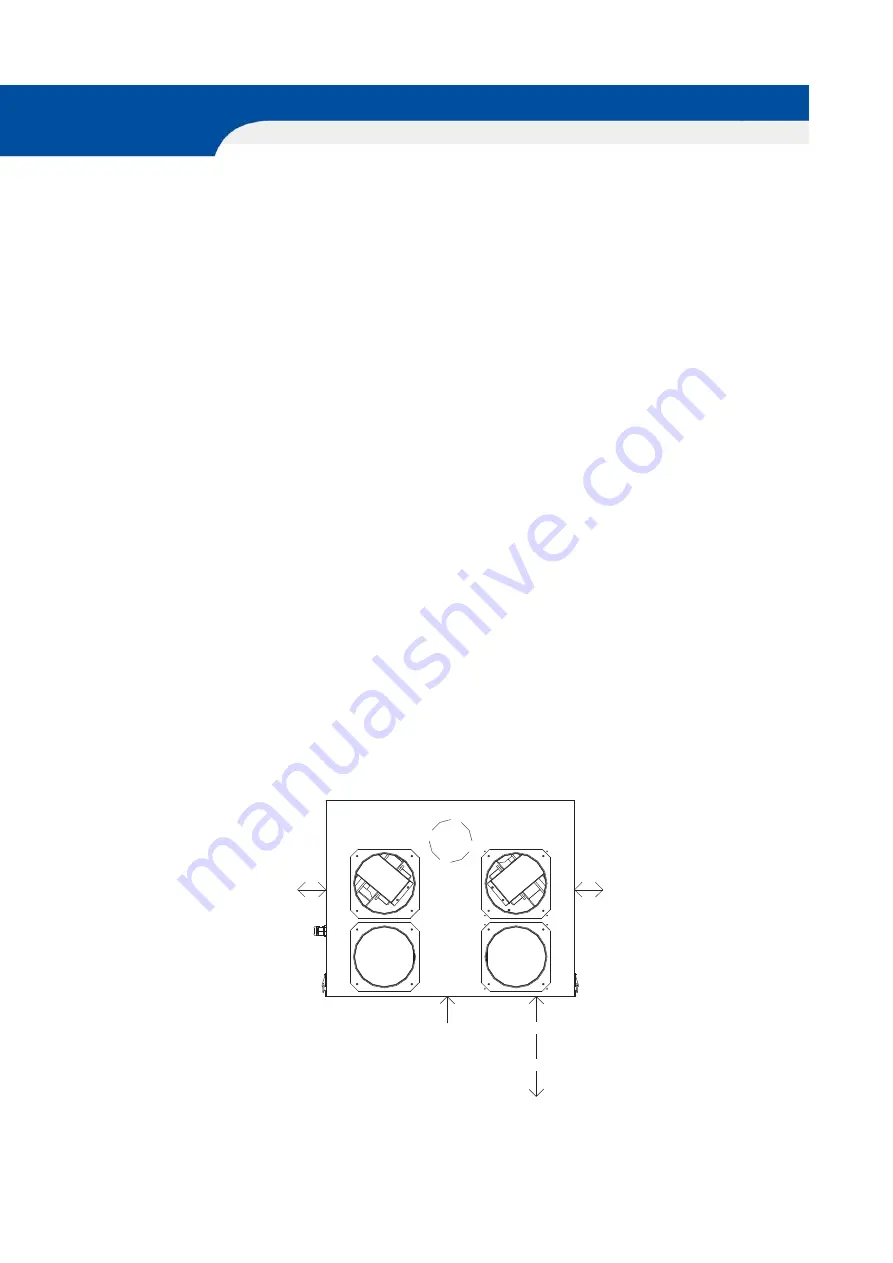

Please reserve enough room for maintenance, refer to below picture

6

80mm reserved

50mm reserved

300mm reserved

RA OA

Compressor

Front of the

ventilator (white)

SA EA