Remove the knob to slide the shift lever through

the slot in the control panel. Secure shift lever to

the shift arm with screws, washers and nuts. Re-

place the knob. Loosen the two bolts on the gear

lever for easier installation.

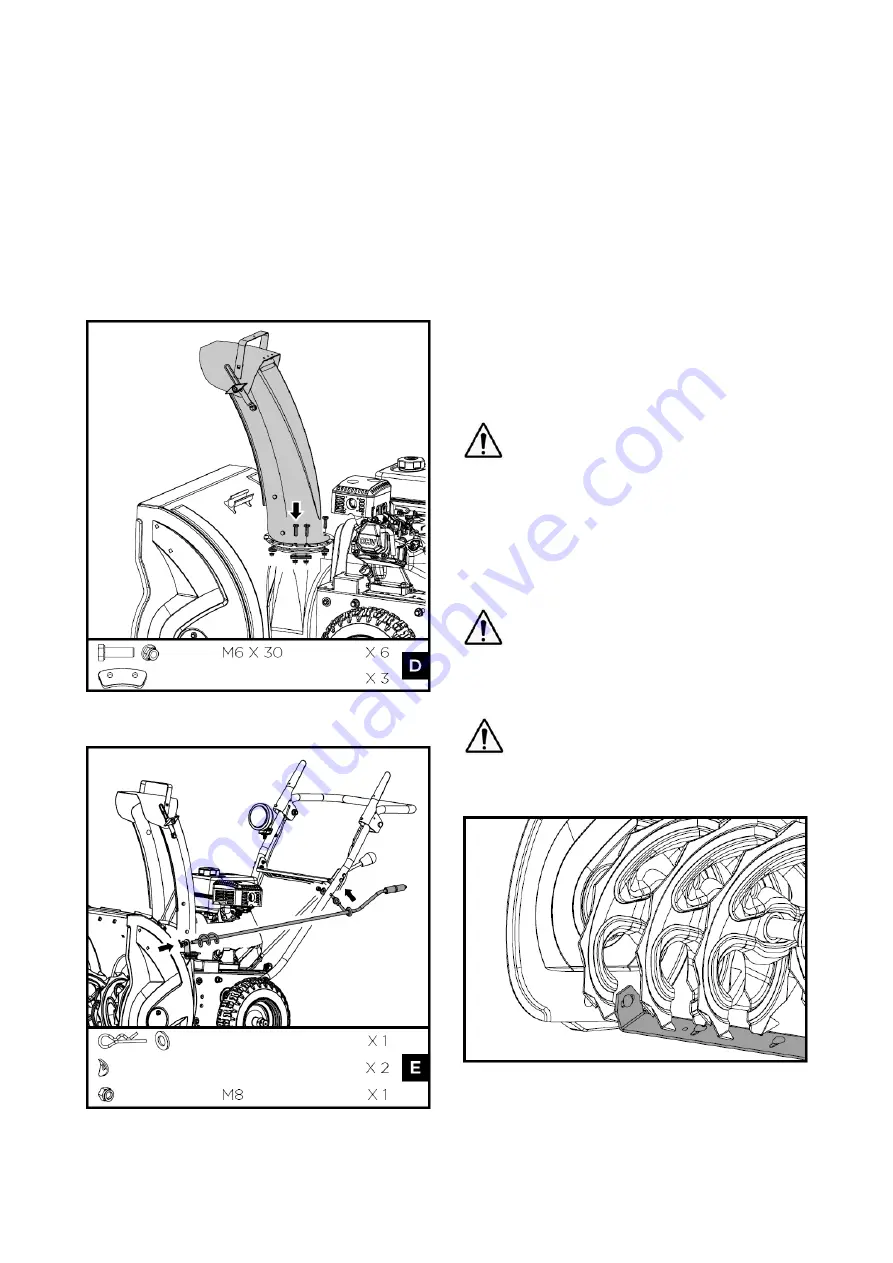

Discharge Chute

1. Grease underside of discharge chute ring (if

not already greased)

2. Install discharge chute over opening in the

auger housing and secure with fasteners.

3. Secure the upper crank lever bracket (at-

tached to the crank lever) to the upper left

side of the handlebar with a locknut and two

curved washers.

4. Apply grease to the spiral of the crank lever.

5. Insert the spiral end of the crank lever into the

lower bracket and secure with the flat washer

and clevis pin.

Tires

The tires are over-inflated at factory for shipping

purposes. Check the pressure in the tires. Re-

duce or Increase equally in both tires to the man-

ufacturer’s recommended pressure.

Under any circumstance do not exceed

manufacturer’s recommended pressure.

Excessive pressure when seating beads

may cause tire/rim assembly to burst with

force sufficient to cause serious injury.

Refer to side wall of tire for recommended

pressure.

Equal tire pressure should be maintained

at all times. If the tire pressure is not

equal in both tires, the machine may not

travel in a straight path and the shave

plate may wear unevenly.

Keep tires free of gasoline and oil, which

can harm rubber.

Skid Shoes

1. Move the machine to a level surface.

2. Support the auger blades so that they are

3mm (1/8”) off the ground.

3. Check the scraper blade adjustment. The

Summary of Contents for XTP120

Page 8: ......

Page 13: ......

Page 18: ......

Page 21: ......

Page 22: ......

Page 29: ......

Page 30: ......

Page 35: ......

Page 40: ......

Page 45: ......

Page 47: ......

Page 49: ......

Page 56: ......

Page 57: ......

Page 62: ......

Page 72: ......

Page 75: ......

Page 76: ......

Page 82: ......

Page 83: ......

Page 84: ......