ET188

12

Belt and Bed

- Your treadmill uses a very high-efficient low-friction bed. Performance is

maximized when the bed is kept as clean as possible. Use a soft, damp cloth or paper towel to

wipe the edge of the belt and the area between the belt edge and frame. Also reach as far as

practical directly under the belt edge. This should be done once a month to extend belt and

bed life. Use water only - no cleaners or abrasives. A mild soap and water solution along with

a nylon scrub brush will clean the top of the textured belt.

Allow the belt to dry before using.

Belt Dust

- This occurs during normal break-in or until the belt stabilizes. Wiping excess off

with a damp cloth will minimize buildup.

General Cleaning

- Dirt, dust, and pet hair can block air inlets and accumulate on the running

belt. On a monthly basis: vacuum underneath your treadmill to prevent buildup. Once a year,

you should remove the black motor hood and vacuum out dirt that may accumulate. UNPLUG

POWER CORD BEFORE THIS TASK.

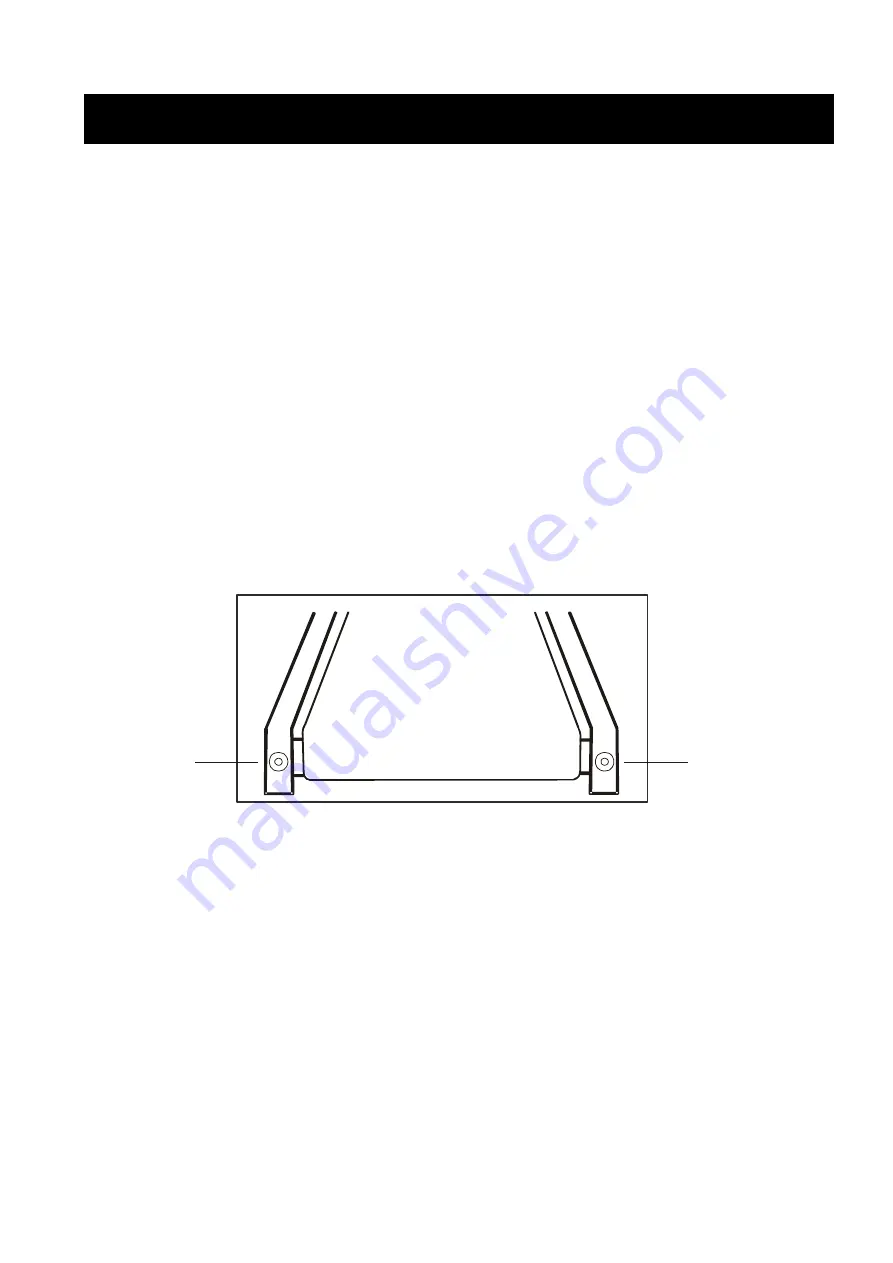

BELT ADJUSTMENTS:

Treadbelt Tension Adjustment

- Belt tension is not critical for most users. It is very important

for joggers and runners in order to provide a smooth, steady running surface. Adjustment must

be made from the right side of the rear roller in order to adjust tension with the 6 mm Allen

wrench provided in the parts package. The adjustment bolt is located at the end of the right

side rail as noted in diagram below.

Tighten the rear roller only enough to prevent slippage at the front roller. Turn the tread-belt

tension adjustment bolt in increments of 1/4 turn and inspect for proper tension.

When an adjustment is made to the belt tension, you must also make a tracking

adjustment to compensate for the change in belt tension.

This is accomplished by turning

both the tension and tracking Allen bolts an equal amount. This adjustment is accomplished by

turning both bolts clockwise no more than a 1/4 turn at a time.

DO NOT OVERTIGHTEN

Over tightening will cause belt damage and premature bearing

failure.

General Maintenance

Note:

Adjustment is through small hole in end

cap.

Tracking / Tension

Adjustment

Tracking / Tension

Adjustment

Summary of Contents for ET188

Page 1: ...OWNER S MANUAL...