13

EST 246

MAINTENANCE AND CLEANING

p

rinciples

for

maintenance

and

cleaning

»

Do not leave dried substances in the sprayer or on the surface.

Removing is difficult (if it is dried) and there can be damage to the

smooth area.

»

Clean holes in the jet system with great care because this is the

most important part representing the quality of the spraying.

»

If necessary, lubricate after cleaning the lever case (27), the

functional part of the regulation bolt (21) and the threads on the

regulation bolts with suitable grease (MOLYKOTE Cu 7439).

»

The sprayer is washed in the respective solvent corresponding

to the type of sprayed coating substance. It is possible to clean

the sprayer in a washing machine for sprayers. Never dip into

the solvent or do not leave the sprayer for a long time in an

environment with solvent vapours.

i

mportant

principles

for

high

-

ouality

function

»

Correctly selected jet set according to the type of the coating

substance and the size of the item (for special requirements

we recommend to contact the technical sales service at the

manufacturer).

»

Correctly treated air for spraying (without dirt, water and oil –

perfectly filtered).

»

Filtered painting substances with the correct viscosity and without

dirt (comply with and follow the instructions of the manufacturers

of the painting substances).

»

Well prepared (cleaned and maintained) painting sprayer.

»

Keep to the recommended pressures of air for spraying.

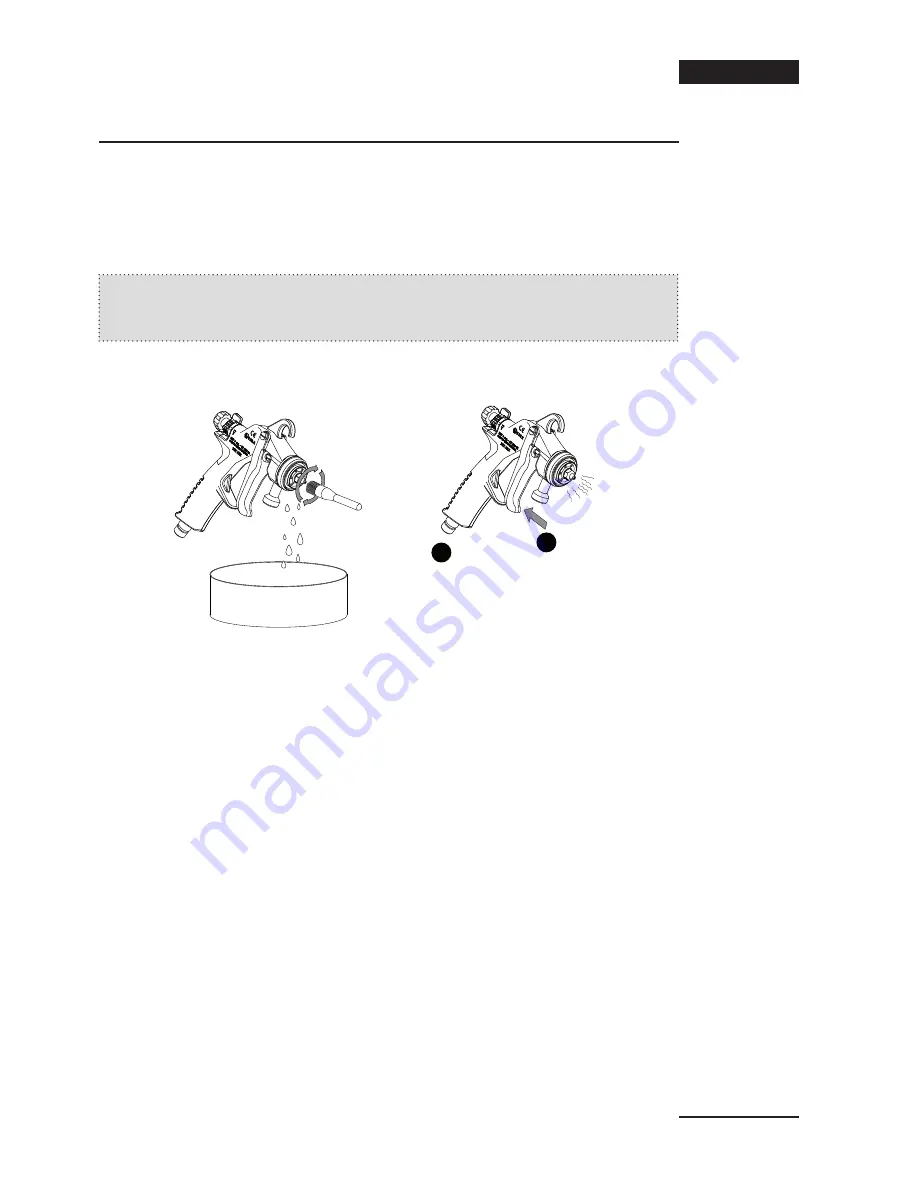

ATTENTION

Do not use metal pieces for cleaning!!!

Connect

pressured air

Blow through

1

2

Summary of Contents for 246

Page 23: ...23 EST 246 ...