Installation of OperatorPush-to-Open

E-S 1000D Series Instruction Manual

2.8

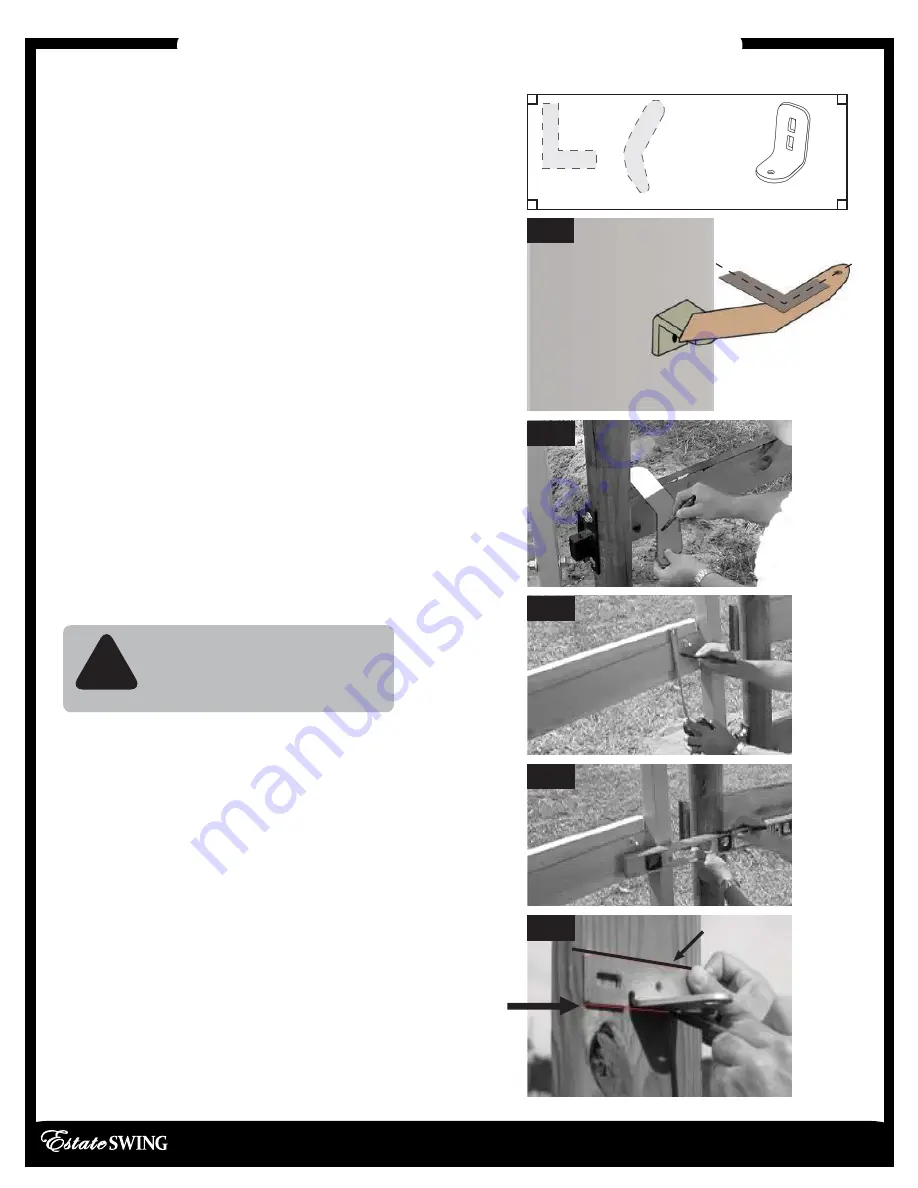

1. Locate the set back template found in the

box to determine the proper setback. Create a

template out of the boomerang bracket by

tracing it on a piece of cardboard.

2. Find the proper setback for your operator

(from previous page). Hold the lower L

shaped bracket along with the boomerang

bracket template against the post near the

hinge. [

See Fig. 1

]

Mark how much of the boomerang bracket you

will trim off on the template.

The hole on the end

of the boomerang bracket should be in the

setback position.

3. Trim boomerang bracket template, then

double check setback positioning.

Using the template, mark the boomerang

bracket for cutting. [

See Fig. 2

]

4. Cut off the excess length (if any) of the

boomerang bracket using a sawzall or

hacksaw.

5. Using a measuring tape, measure vertically to

find the center of the horizontal mount on the

gate, then place a mark. [

See Fig. 3

]

6. Utilizing a level, measure from the center of

the horizontal mount of the gate to the post to

the get bracket position. Place a mark on the

post at this point. [

See Fig. 4

]

7. Temporarily position the gate bracket on the

post. Align the top of the gate bracket with the

marking created in the previous step. Make an

additional mark at the bottom of the gate

bracket. This will mark the position for the top of

the lower L shaped bracket. [

See Fig. 5

]

!

CAUTION:

Observe all safety

precautions recommended

by manufacturer of the

cutting tool.

Setback

Template

“Boomerang”

Bracket

Template

“L” Shaped Bracket

Fig. 2

Fig. 3

Fig. 4

Fig. 5

Fig. 1

Original Line

Summary of Contents for E-S 1000D Series

Page 4: ...Section 1 Review of Specifications Warnings and Tools E S 1000D Series Instruction Manual ...

Page 5: ......

Page 10: ...Section 2 Installation of Mounting Brackets E S 1000D Series Instruction Manual ...

Page 11: ......

Page 21: ...Section 3 Gate Operator Mounting Wiring Motors Power E S 1000D Series Instruction Manual ...

Page 22: ......

Page 32: ...Section 4 Start Up Operation E S 1000D Series Instruction Manual ...

Page 33: ......

Page 37: ...Section 5 Maintenance Troubleshooting Accessories E S 1000D Series Instruction Manual ...

Page 38: ......