ProNet series AC servo system User’s manual V.1.08

- 36 -

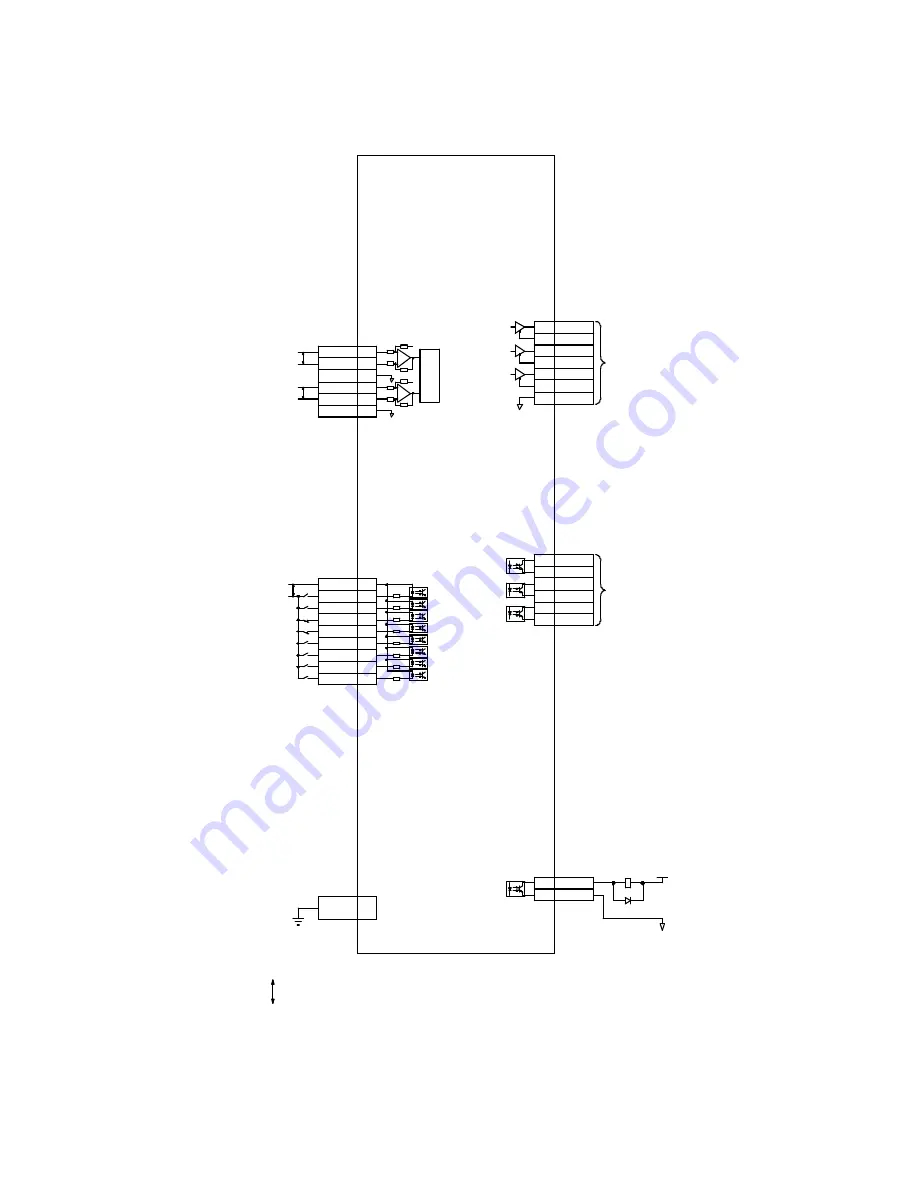

3.5.6 Torque Control Mode

+

A /D

3.3K Ω

+24V

P

P

P

-

-

+

ref

ref

40K

10K

40K

10K

1

Ry

1D

+24

V

0

V

PAO+

20

PAO-

21

PBO+

22

PBO-

23

PCO+

24

PCO-

25

DGND

50

TGON+

5

TGON-

6

S-RDY+

9

S-RDY-

10

V-CMP+

11

V-CMP-

12

ALM+

7

ALM-

8

VREF+

1

VREF-

2

AGND

3

TREF+

26

TREF-

27

AGND

28

DICOM

13

S-ON

14

P-CON

15

P-OT

16

N-OT

17

ALM-RST 39

CLR

40

P-CL

41

N-CL

42

Shield

ProNet

Series Servodrives

Speed Limit Input(±1V~10V/Rated Speed)

Torque Limit Input (±1V~10V/Rated Torque)

Signal allocatons can be modified:

S-ON: Servo ON

P-CON: P Control

P- OT: For war d Run Pr ohibited

N- OT: Rever se Run Pr ohibited

ALM-RST: Alarm Reset

CLR: Clear Error Pulse

P- CL: For war d Tor que Limit

N- CL: Rever se Tor que Limit

Connect Shield to Connector Shell.

Represents Twisted-pair Wires

Shell

ALM: Servo Alarm Output

Photocoupler Output:

Maximum Operating Voltage:DC30V

Maximum Output Current:DC50mA

Signal Allocations can be Modified:

V-CMP: Speed Coincidence

COIN: Positioning Completion

TGON:Rotation Detection

S-RDY:Servo Ready

CLT:Torque Limit Detection

BK:Brake Interlock

PGC: Encoder C-Pulse Output

PG Divided Ratio Output:

Applicable Line Receiver

AM26LS32A Manufactured by TI or the Equivalent.