Chapter 4 Operation

- 72 -

4.6.2 Setting the Electronic Gear

(

1

1

1

1

)

Electronic

Electronic

Electronic

Electronic Gear

Gear

Gear

Gear

The electronic gear enables the workpiece travel distance per input reference pulse from the host

controller to be set to any value.

One reference pulse from the host controller, i.e., the minimum position data unit, is called a reference

unit.

(

2

2

2

2

)

Related

Related

Related

Related Parameters

Parameters

Parameters

Parameters

Pn201

Electronic Gear Ratio(Numerator)

Setting

Setting

Setting

Setting Range

Range

Range

Range

Setting

Setting

Setting

Setting Unit

Unit

Unit

Unit

Factory

Factory

Factory

Factory Setting

Setting

Setting

Setting

Setting

Setting

Setting

Setting Validation

Validation

Validation

Validation

1

~

65535

—

1

After restart

Pn202

Electronic Gear Ratio(Denominator)

Setting

Setting

Setting

Setting Range

Range

Range

Range

Setting

Setting

Setting

Setting Unit

Unit

Unit

Unit

Factory

Factory

Factory

Factory Setting

Setting

Setting

Setting

Setting

Setting

Setting

Setting Validation

Validation

Validation

Validation

1

~

65535

—

1

After restart

If the deceleration ratio of the servomotor and the load shaft is given as n/m where m is the

rotation of the servomotor and n is the rotation of the load shaft.

Electronic gear ratio:

202

201

Pn

Pn

A

B

=

n

m

units

reference

revolution

shaft

load

per

ce

dis

Travel

pulses

encoder

of

No

×

×

=

)

(

tan

4

.

* If the ratio is outside the setting range, reduce the fraction (both numerator and denominator) until you

obtain integers within the range.

* Be careful not to change the electronic gear ratio (B/A).

■Important

Electronic gear ratio setting range: 0.01≤electronic gear ratio(B/A)≤ 100

If the electronic gear ratio is outside this range, the servodrive will not operate properly. In this case,

modify the load configuration or reference unit.

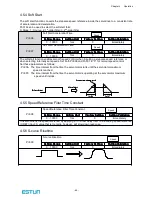

When the Electronic Gear is Not Used

When the Electronic Gear is Used

workpiece

workpiece

N o . of encoder

p u ls e s

:

3 2 7 6 8

Ball screw pitch

:

6m m

N o . of encoder

p u ls e s

:

3 2 7 6 8

Ball screw pitch

:

6 m m

One revolution is 6m m . Therefore 1 0 ÷6

=

1.6 6 6 6 revolutions .

3 2 7 6 8 ×4 pulses is one revolution .

Therefore, 1.6 6 6 6 ×3 2 7 6 8 ×4

=

218448

p u ls e s. 218448 pulses are input as

reference pulses.

The equation must be calculated at the

host controller .

To move a workpiece 1 0 mm :

The reference unit is 1 µm. Therefore, to

move the workpiece 1 0 mm (1 0 0 0 0 µm),

1p u lse =1µm, so 1 0 0 0 0 /1

=

10000 p u ls e s.

Input 10000 pulses per 1 0 mm of

workpiece movement .

To move a workpiece 1 0 mm using

reference units:

Reference unit

:

1µm

Position

Position