Chapter 4

Operation

- 73 -

(3)Procedure

(3)Procedure

(3)Procedure

(3)Procedure for

for

for

for Setting

Setting

Setting

Setting the

the

the

the Electronic

Electronic

Electronic

Electronic Gear

Gear

Gear

Gear Ratio

Ratio

Ratio

Ratio

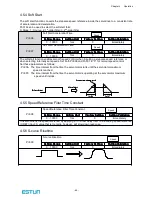

Use the following procedure to set the electronic gear ratio.

(4)Electronic

(4)Electronic

(4)Electronic

(4)Electronic Gear

Gear

Gear

Gear Ratio

Ratio

Ratio

Ratio Setting

Setting

Setting

Setting Examples

Examples

Examples

Examples

The following examples show electronic gear ratio settings for different load configurations.

Reduce the fraction (both numerator and denominator) if the calculated result will not be within the setting range.

For example, reduce the above numerators and denominators by four or other numbers to obtain the final results in step

7 and complete the settings.

Step

Step

Step

Step

Operation

Operation

Operation

Operation

Description

Description

Description

Description

1

Check machine specifications.

Check the deceleration ratio, ball screw pitch and pulley

diameter.

2

Check the number of encoder

pulses.

Check the number of encoder pulses for the servomotor used.

3

Determine the reference unit used.

Determine the reference unit from the host controller,

considering the machine specifications and positioning

accuracy.

4

Calculate the travel distance per load

shaft revolution.

Calculate the number of reference units necessary to turn the

load shaft one revolution based on the previously determined

reference units.s

5

Calculate the electronic gear ratio.

Use the electronic gear ratio equation to calculate the ratio

(B/A).

6

Set parameters.

Set parameters using the calculated values.

Step

Step

Step

Step

Operation

Operation

Operation

Operation

Load

Load

Load

Load Configuration

Configuration

Configuration

Configuration

Ball

Ball

Ball

Ball Screw

Screw

Screw

Screw

Disc

Disc

Disc

Disc Table

Table

Table

Table

Belt

Belt

Belt

Belt and

and

and

and Pulley

Pulley

Pulley

Pulley

1 7

1 7

1 7

1 7 ----bit e nc ode r

bit e nc ode r

bit e nc ode r

bit e nc ode r

Ball sc r e w pitc h

Ball sc r e w pitc h

Ball sc r e w pitc h

Ball sc r e w pitc h

:

6

6

6

6m m

m m

m m

m m

R eference unit

R eference unit

R eference unit

R eference unit

:

0

0

0

0....0 0 1

0 0 1

0 0 1

0 0 1 m m

m m

m m

m m

Load shaft

Load shaft

Load shaft

Load shaft

R eference unit

R eference unit

R eference unit

R eference unit

:

0

0

0

0....1

1

1

1

º

Lo a d s ha ft

Lo a d s ha ft

Lo a d s ha ft

Lo a d s ha ft

1 7

1 7

1 7

1 7 ----bit enco der

bit enco der

bit enco der

bit enco der

D ecelera tio n ra tio

D ecelera tio n ra tio

D ecelera tio n ra tio

D ecelera tio n ra tio

: : : :

3

3

3

3

:

1

1

1

1

R eference unit

R eference unit

R eference unit

R eference unit

:

0

0

0

0....0 1

0 1

0 1

0 1 m m

m m

m m

m m

Load shaft

Load shaft

Load shaft

Load shaft

D eceleration ratio

D eceleration ratio

D eceleration ratio

D eceleration ratio ::::

2

2

2

2

:

1

1

1

1

1 7

1 7

1 7

1 7 ----bit encoder

bit encoder

bit encoder

bit encoder

Pulley diam eter

Pulley diam eter

Pulley diam eter

Pulley diam eter ::::

Φ

Φ

Φ

Φ1 0 0

1 0 0

1 0 0

1 0 0 m m

m m

m m

m m

1

Check

machine

specifications.

Ball screw pitch:mm

Deceleration ratio:/1

Rotation angle per revolution

:360° eceleration ratio:3/1

Pulley diameter:100 mm

(pulley circumference:314 mm)

·Deceleration ratio:2/1

2

Encoder

17-bit:32768P/R

17-bit:32768P/R

17-bit:32768P/R

3

Determine the

rference unit

used

1 reference unit:

0.001mm(1μm)

1 reference unit:0.1°

1 reference unit:0.01mm

4

Calculate the

travel distance

per load shaft

revolution

6mm/0.001mm=6000

360°/0.1°=3600

314mm/0.01mm=31400

5

Calculate the

electronic gear

ratio

1

1

6000

4

32768

×

×

=

A

B

1

3

3600

4

32768

×

×

=

A

B

1

2

31400

4

32768

×

×

=

A

B

6

Set parameters

Pn201

131072

Pn201

393216

Pn201

262144

Pn202

6000

Pn202

3600

Pn202

31400

7

Final Result

Pn201

32768

Pn201

32768

Pn201

32768

Pn202

1500

Pn202

300

Pn202

3925