11

10

Operation (Continued)

Operation (Continued)

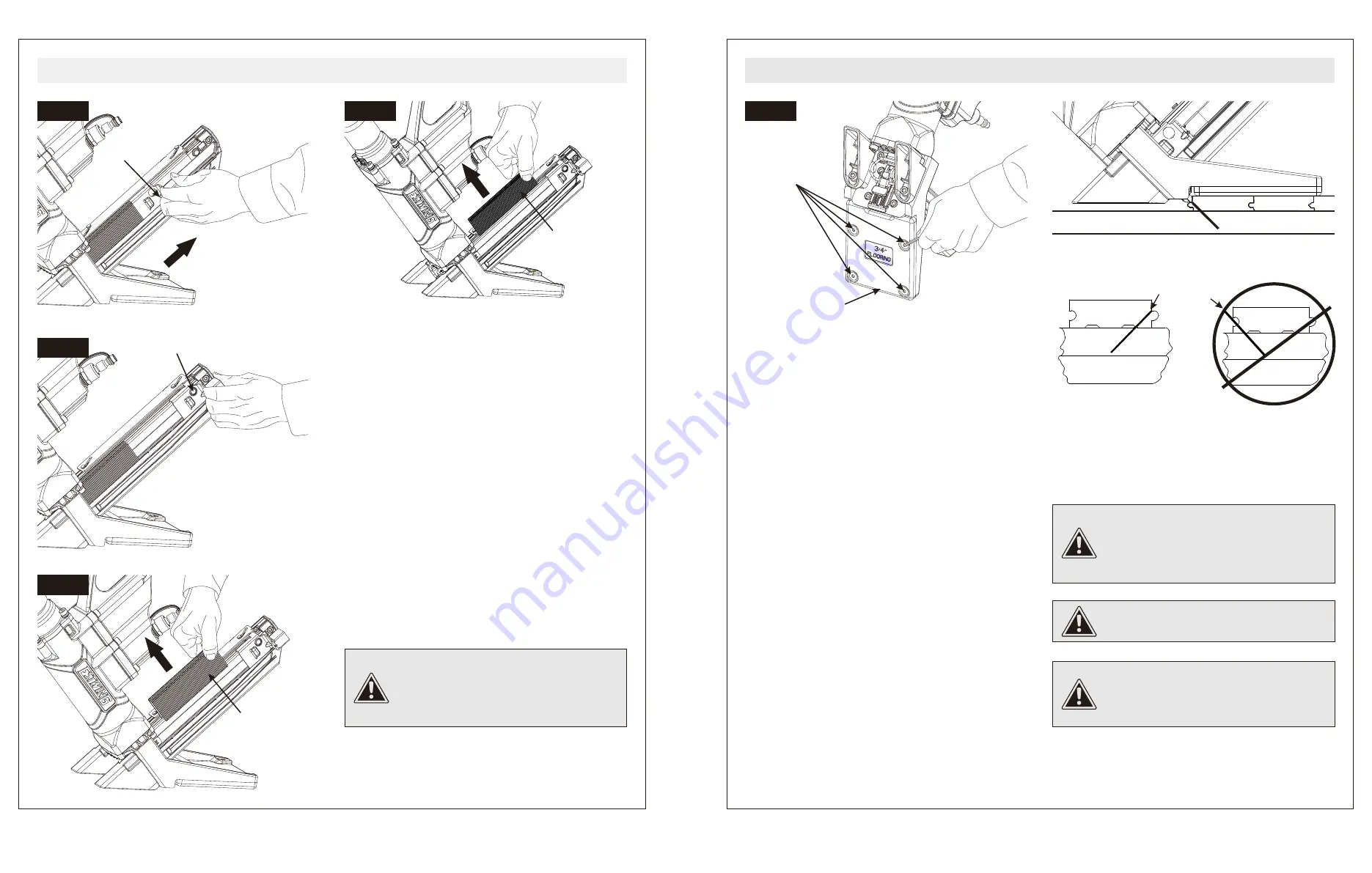

Figure 8

Sl

ide

Ba

ck

Pusher(A)

Figure 9

Lock Button(B)

Figure 10

WARNING: Disconnect the tool from the air

source whenever changing the foot plate.

Make sure there is no fastener in the magazine

before changing the foot plate.

Changing the foot plate

4

Staple

L Cleat

Screws (E)

Foot plate (D)

Setting the air pressure

5

The amount of air pressure required depends on the

size of the fasteners and the workpiece material.

Begin testing the depth of drive by driving a test nail

into the same type of workpiece material used for the

actual job.

Drive a test fastener with the air pressure set at 90-95

psi.

Raise or lower the air pressure to find the lowest

setting that will perform the job with consistent

results.

Operating the tool

6

Attach the tool to the air source. Start your

compressor and check the pressure, making sure it is

set between 70-115 psi. Do not exceed the maximum

115 psi.

Hold the hand grip (J) securely and press the foot

plate (D) to the work surface. Make sure the plate is

over the fastener target position.

Press down firmly so that the foot plate (D) is firmly

contacting the work surface. Then, using the mallet

packed with the tool, strike the hammer cap (K) firmly

to drive the fastener into work surface. Lift the tool off

the work surface. Repeat this process until the job is

completed.

1.

2.

3.

4.

1.

2.

3.

The flooring nailer is designed for tongue and groove

flooring only. Place the nailer flush onto the work surface

and ensure that you are striking at the tongue of the

hardwood floor.

Tongue and groove flooring

WARNING: Extreme caution must be used

whenever this tool is connected to an air source.

If the tool is dropped, or if the hammer cap (K) is

accidentally struck, then the tool will fire a

fastener, potentially causing SERIOUS

PERSONAL INJURY.

WARNING: Keep your feet off the tool.

When finished, make sure to store the tool in a clean,

dry, safe location out of reach of children and other

unauthorized People.

4.

Correct Placement

SUBFLOOR

Incorrect Placement

Lcleat

or

Staples

TONGUE & GROOVE

FLOORING

TONGUE & GROOVE

FLOORING

SUBFLOOR

NOTE: Please follow your wood manufacture’s guideline

when doing your flooring installations.

WARNING: Before using the tool on a floor, test

the tool on a scrap piece of wood. Adjust the

driving depth by providing more or less air

pressure. Never exceed 115 PSI.

Figure 11

Figure 12

Disconnect the tool from the air source.

Empty the magazine completely.

Fire the tool into a piece of scrap wood to ensure

there is no compressed air or fasteners left in the tool.

Set the tool on its side to expose the four screws (E).

Remove the four screws (E), then remove the foot

plate(D). (See figure 12)

Align the four screw holes in the replacement foot

plate with the four threaded mounting holes.

Using the four screws you removed, secure the

replacement foot plate to the tool.

Ensure the correct foot plate is installed by firing into

a scrap piece of flooring and checking for proper

fastener placement.

The tool is equipped with a factory pre-installed 3/4 in.

foot plate (D), and an additional uninstalled

5/8 in. & 9/16

in. foot plate .

To change the plate:

1.

2.

3.

4.

5.

6.

7.

8.

Lcleat

or

Staples