35

11.1.2. Adjustments for other Motors / „Fine Tuning“

Unfortunately, the motors available in the market have

considerable variations due to tolerances. This is even true for

the same type. Therefore, LokPilot decoders enable you to adapt

load compensation to the motor with CVs 53, 54 and 55. If the

recommended values above do not lead to acceptable results,

you can further optimise them.

However, before doing this you must make sure that there are

no capacitors wired between the motor terminals and the chassis.

The commutator of the motor must be clean and the drive system

should run freely. The wheel contacts and other contact plates of

the locomotive must also be clean and make reliable contact.

11.1.2.1. Parameter „K“

Parameter „K“, stored in CV 54, influences how strongly load

control will affect the driving performance. The higher the value,

the more load control will respond to any changes and try to

adjust the revs of the motor.

Parameter „K“ needs adjustment if the locomotive runs unevenly

(jerks) in speed step 1.

Reduce the value of CV 54 by 5 and test-run the locomotive to

see if there are any improvements. Repeat these steps until the

locomotive runs smoothly at speed step 1.

With some motors, it may be necessary to set the starting voltage

to a value between 4 and 6 in order to arrive at good results.

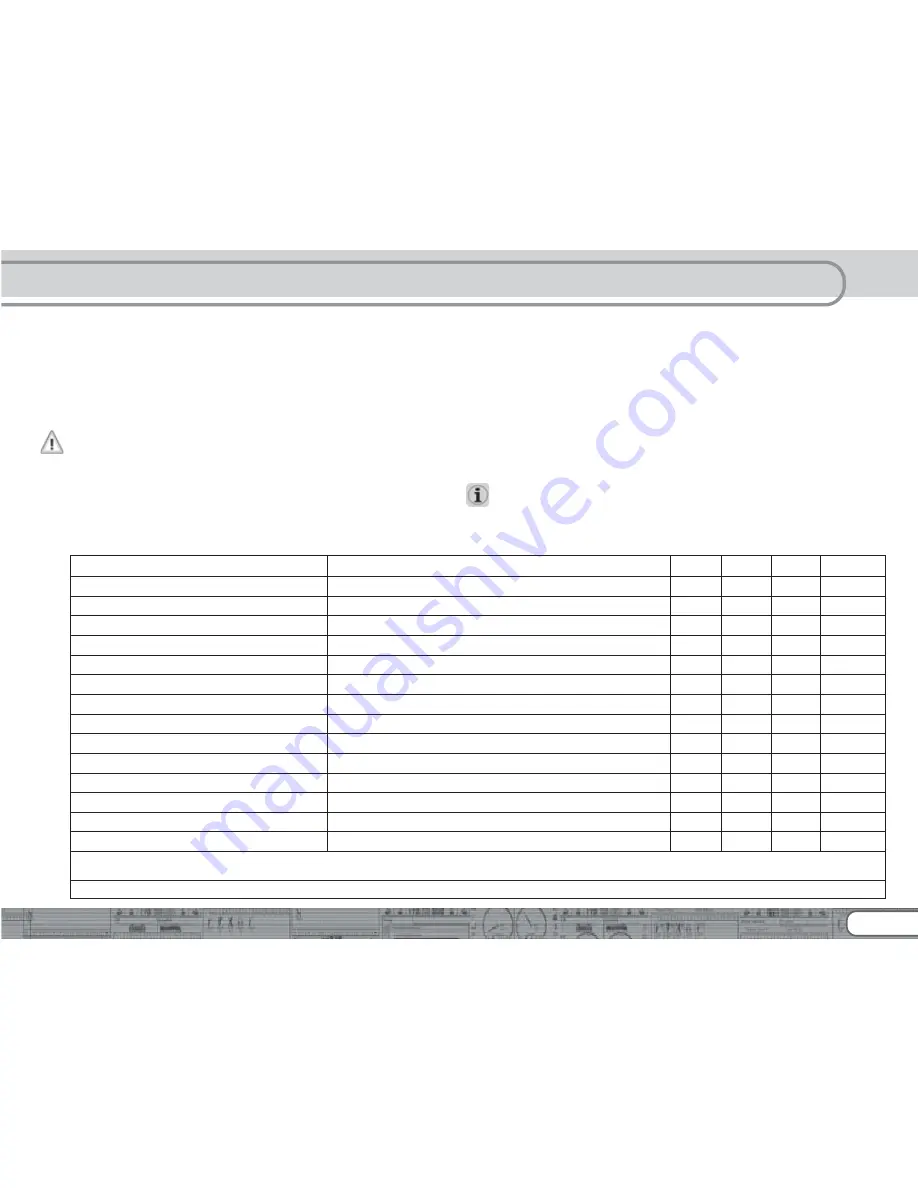

Motor Control

type of motor

type of motor

type of motor

type of motor

type of motor

rrrrremarks

emarks

emarks

emarks

emarks

CV 2

CV 2

CV 2

CV 2

CV 2

CV 53

CV 53

CV 53

CV 53

CV 53

CV 54

CV 54

CV 54

CV 54

CV 54

CV 55

CV 55

CV 55

CV 55

CV 55

Fleischmann® motor

6

40

16

20

Märklin® SFCM small „Scheibenkollektormotor“ using Magnet 51961

6

20

16

12

Märklin® LFCM big „Scheibenkollektormotor“

using Magnet 51960

6

50

16

12

Märklin® DCM „Trommelkollektormotor“

using Magnet 51962

6

40

16

12

Märklin® 5*-high performance motor

3

40

20

38

Märklin® locomotives using Maxon motors

4

56

6 – 8

4 – 6

HAG ® motors

4

56

10

10

Trix® locomotives using Maxon Motor

remove the motor EMC capacitors from the main board!

4

56

6 - 8

4 – 6

Piko® locomotives

6

40

10 – 14 30

Gützold locomotives

(set Motor-frequency to 15 kHz, refer chapter 10.3.)

4

56

20

30

Faulhaber® motors

CV55 depends on flywheel: Sometimes CV55=30

6

40

6 – 10

8 - 10

LGB® locomotives

Using LokPilot XL V3.0

6

56

8

30

Rivarossi®

Locomotives from old production (before Hornby!)

8

30

15

40

Trix®, Fleischmann®, Roco® N scale

CV 55 depends of size of flywheel

6 – 10

50

20 –25

25 – 30

Figure 15: table of BACK-EMF settings for widely used motors

Summary of Contents for LokPilot Fx micro V3.0

Page 69: ...69 For your personal notes ...