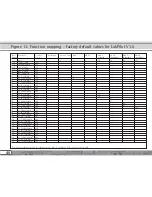

51

CV

Name

Description

Range Value

29

Configuration register

The most complex CV within the DCC standards.

4

This register contains important information, some of which are only relevant

for DCC operation

Bit Function

Value

0

Reverse direction of travel (forward becomes reverse)

Normal direction

0

Reversed direction

1

1

Speed steps (For DCC-opearation only)

14 speed steps

0

28 or 128 speed steps

2

2

analog operation

Disable analog operation (no function on conventional layout)

0

Enable analog operation

4

3

RailCom communication

Disable RailCom

0

Enable RailCom

8

4

Selection of speed curve

speed curve through CV 2, 5, 6

0

speed curve through CV 67 - 96

16

5

Selection of engine address (only for DCC operation)

short addresses (CV 1) in DCC mode

0

long addresses (CV 17+CV18) in DCC mode

32

Summary of Contents for LokPilot Fx micro V3.0

Page 69: ...69 For your personal notes ...