14

www.eta.co.at

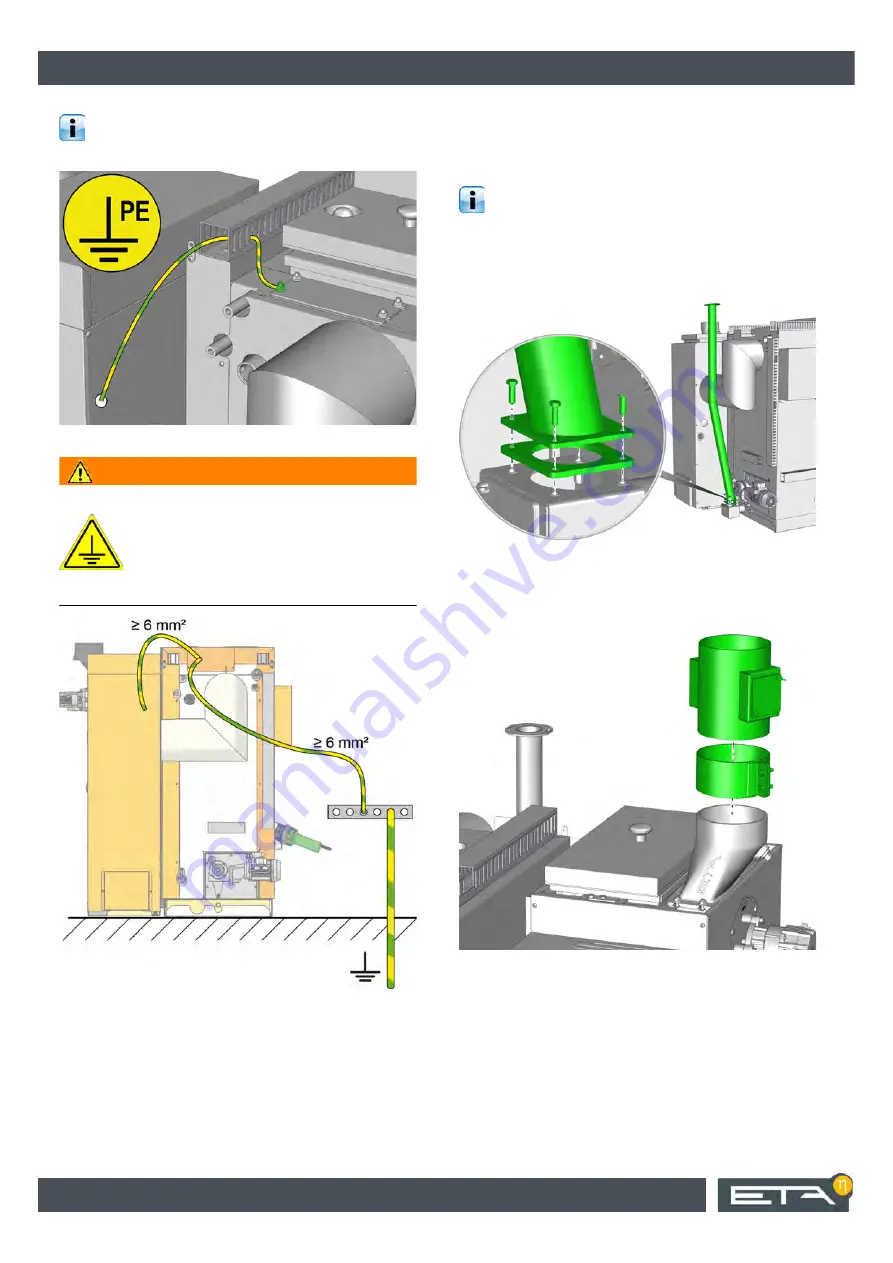

Installing flue gas recirculation

Installation

Fasten the separate earthing cable (6 mm²) of

the precipitator to a nut on the boiler flue gas

connection using a lock washer.

Fig. 5-4: Earthing cable

WARNING!

Earthing of the boiler is required

Separate earthing is required for the boiler.

To do so, a connection must be established

between the boiler and the structural

potential equalisation in the boiler room

(minimum cross-section 6 mm²).

5.3

Installing flue gas recirculation

Mount flue gas recirculation

The following steps are only required if the boiler

is equipped with flue gas recirculation.

Before starting installation, dismantle the existing

piping for the flue gas recirculation on the back of the

boiler. Fasten the vertical flue pipe with the supplied

seal to the lower duct.

Fig. 5-5: Vertical flue pipe

Use a pipe clamp to mount the joint for the flue gas re-

circulation onto the precipitator. Only hand-tighten the

screws of the pipe clamp.

Fig. 5-6: Joint

Summary of Contents for EEP 130

Page 30: ...www eta co at ...

Page 31: ......

Page 32: ...www eta co at www eta co at downloads DOWNLOAD ...