Installation

Connecting piping

35

10.3

Connecting piping

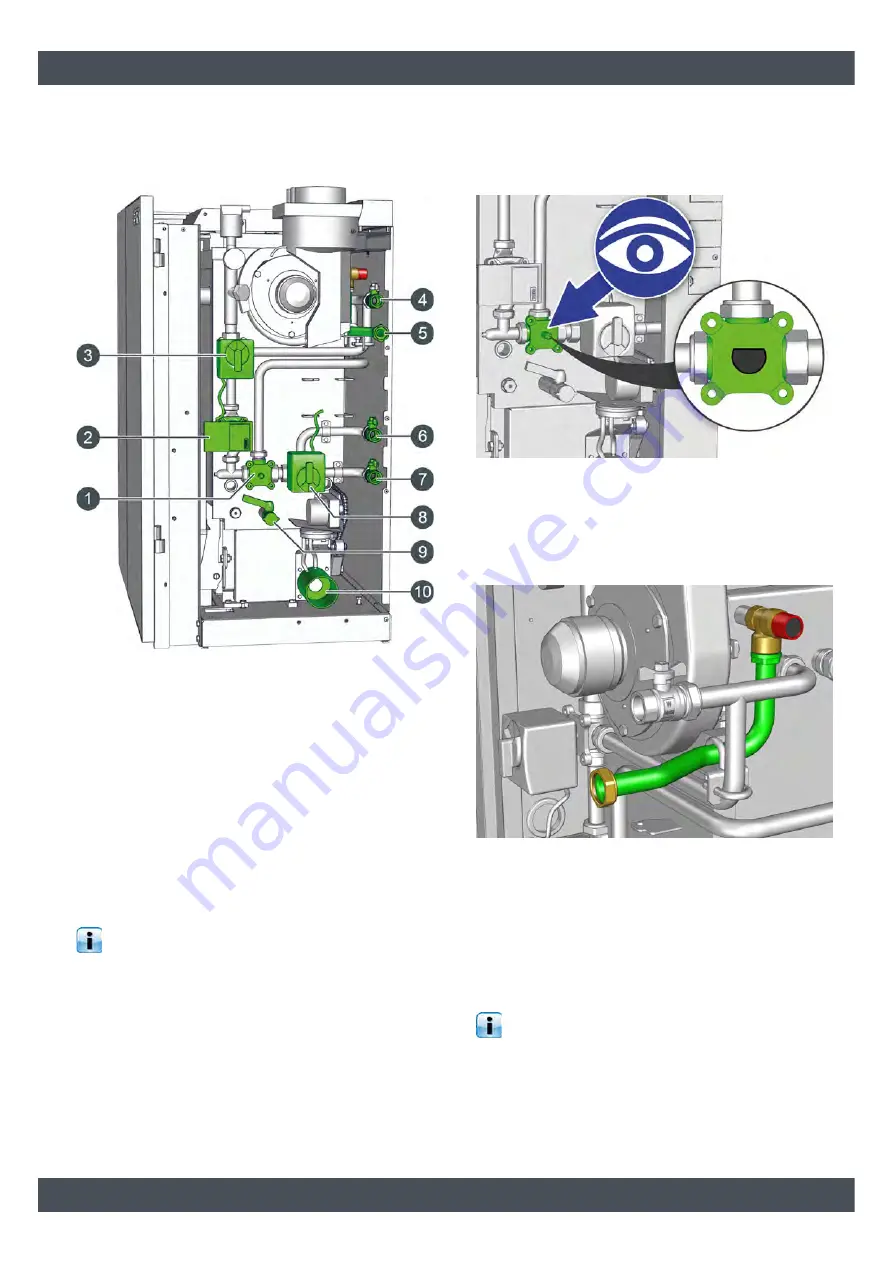

Connecting the piping to the boiler

1

Return riser mixing valve

2

Boiler pump

3

Flow mixing valve with actuator

4

Return

5

Safety valve outlet

6

Hot water tank flow

7

Heating circuit flow

8

Changeover valve between heating circuit and hot

water tank

9

Discharge

10 Air connection for operation with external air

supply

The actuator is attached to the flow mixing valve

to regulate the feed temperature in the heating

circuit.

Check position of return riser mixing valve

Check the position of the return riser mixing valve. The

flattening on its shaft must face upwards, Indicating

that the bypass pipe is blocked.

Fig. 10-9: Return riser mixing valve

Connecting the piping for the safety valve outlet

A safety valve is already installed on the boiler and its

discharge pipe extends out of the boiler (3/4"

coupling).

Fig. 10-10: Boiler safety valve

On site further piping is to be connected to this

coupling for the discharge pipe of the safety valve. The

end of this discharge pipe must be routed into the

sewage system (e.g. duct) via a siphon.

Contact thermostats required for underfloor and

wall heating

For safety reasons, contact thermostats must be

installed for operation with underfloor and wall

heating. In the event of a malfunction, they switch off

the affected heating circuit to protect it from

excessively high flow temperatures.

Summary of Contents for PelletsCompact

Page 1: ...2020 07 21 EN 0000000061 V 022 1513 93003 003 PelletsUnit 7 15 kW Installation ...

Page 41: ...Installation Network connection 41 ...

Page 45: ...Electrical connections Overview of circuit boards 45 ...

Page 49: ...Electrical connections PE C4 circuit board 49 ...

Page 66: ...www eta co at ...

Page 67: ......

Page 68: ...www eta co at www eta co at downloads DOWNLOAD ...