Pellet store

General information

53

12 Pellet store

12.1

General information

Delivery of pellets

The pellets are delivered by a tank truck and blown into

the storage room. The tank trucks usually have a pump

hose with a length of up to 20 m. If you expect to need

a longer pump hose, ask about your pellet supplier's

technical capabilities.

Vehicle access should be at least 3 m wide and 4 m

high. The truck can only back up if the street and gate

are wide enough.

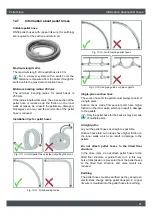

1

Pellet store

2

Boiler room

3

Filling hoses from tank truck

Correct placement of the pellet store

Placement of the storeroom is crucial for satisfactory

operation. For this reason, do not place the pellet store

underneath or in the immediate vicinity of bedrooms.

Because the noises that occur during operation could

be transferred into these rooms.

Position of pellet store and boiler room

If possible, the pellet store should adjoin an outer wall

since the filling nozzle should be accessible from

outside. For an interior pellet store, the blower and

back air pipes should be extended to the outer wall.

The boiler room should adjoin an outer wall to ensure

direct supply of combustion air to the pellet boiler. For

an interior boiler room, an air supply duct must lead

from the boiler room to the outer wall.

If the pellet store is located above the boiler (e.g.,

heating boilers in the basement and the pellet

store on the ground floor or attic) condensation can

occur in the pellet hoses.

To prevent this, a check valve can be installed in the

pellet hose of the return air line (from the boiler to the

pellet store). This prevents air circulation from the

lower boiler to the pellet store.

Testing before initial fill-up

Before filling the pellet store, test the functionality

of the entire heating system and the pellet

conveying system. For this purpose, deposit some

pellets (bagged product) in the storage room near the

discharge conveyor.

Only fill up the pellet store after this test has been

completed successfully.

Burn-back protection also when filling

The authorities or the chimney sweep often require

that a notice saying "CAUTION! Switch off boiler

before filling" must be affixed, easily visible, to the

filling nozzle covers. Burn-back flaps and sliders at the

boiler's combustion chamber are open during

operation, so during boiler operation, hot gases can be

sucked into the path of the pellets (due to negative-

pressure in the fuel deposit) or air can be blown

through the fuel path (due to overpressure in the fuel

deposit). Both effects can cause a fire. Strictly

speaking, the boiler should already be switched off two

hours before filling the pellet store, because the burn-

back flaps and sliders do not always close completely.

So there should be no more fire in the boiler when

filling pellets.

Since we at ETA don't want to leave the burn-

back protection of our boilers to chance, we equip

all ETA pellet boilers with a rotary valve so that even

during operation there is no open connection between

the combustion chamber and the pellet store. Though

it is not required that an ETA pellet boiler be switched

off while filling the pellet store, you should do so

anyway if the driver of the delivery truck requests it.

Dust-tight doors to pellet store

Doors and other openings must open outward and be

furnished with a circumferential dust-tight seal. For

doors or other openings to the pellet store, wooden

Summary of Contents for PelletsCompact

Page 1: ...2020 07 21 EN 0000000061 V 022 1513 93003 003 PelletsUnit 7 15 kW Installation ...

Page 41: ...Installation Network connection 41 ...

Page 45: ...Electrical connections Overview of circuit boards 45 ...

Page 49: ...Electrical connections PE C4 circuit board 49 ...

Page 66: ...www eta co at ...

Page 67: ......

Page 68: ...www eta co at www eta co at downloads DOWNLOAD ...