Start-up

21

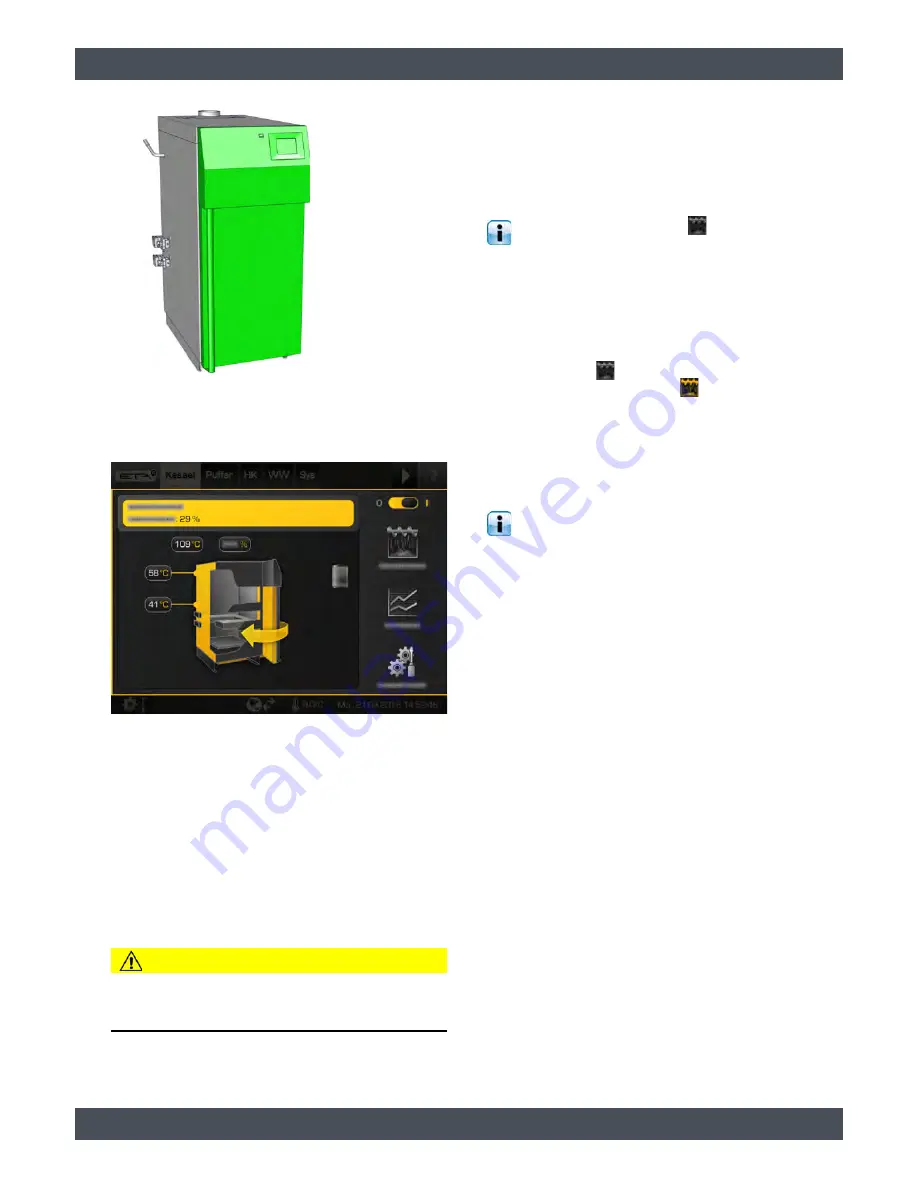

Fig. 8-2: Close insulation door

The exhaust temperature is displayed in the boiler

overview. At over 100°C, an arrow appears to indicate

that the ignition door should be closed.

When the insulating door is closed, the boiler automat-

ically switches to [Ignition] mode and, once the

residual oxygen content is below 15%, to [Heating]

mode. The boiler is now in heating mode and regulates

the combustion of the wood independently.

Avoid opening boiler doors unnecessarily

Avoid opening the insulating door and the fuel

chamber door unnecessarily in [Heating] status. That

disrupts the boiler control and increases fuel consump-

tion. Also keep the ignition door and the combustion

chamber door closed.

CAUTION!

Never open the insulating door and the fuel

chamber door when the boiler is in [Calibrating

lambda probe] or [Overtemperature] status.

Completion of heating mode with ember burnout

Once the wood in the boiler has been burned (residual

oxygen content above 15% for more than 5 minutes) or

the exhaust temperature falls below 80 °C, the boiler

automatically starts the ember burnout ([Ember

burnout] status).

If the [Ember burnout]

button was not

pressed, the boiler will flush the secondary air

ducts with air in order to free them of dust. Charcoal

and embers remain in the boiler by design so that

newly added wood can be ignited more easily.

Complete ember burnout for cleaning

To clean after the final heating operation, press the

[Ember burnout]

button in the log boiler overview

(the button will then turn yellow

). Ember retention is

then deactivated and the boiler performs a complete

ember burnout (duration approx. 1 hour). burning most

of the charcoal in the fuel chamber to make

subsequent cleaning of the boiler easier.

Adding fuel

You should only add fuel when the buffer

charging status is below 30% and the fuel

chamber has burned to empty.

If wood has been added and there are still embers in

the boiler, it automatically tries to ignite the wood

again. If the wood is hard to ignite and there are only a

few remaining embers, it may help to push the

charcoal together in the middle before refilling. If the

remaining embers do not ignite the wood, light it with

paper and cardboard through the ignition door.

Summary of Contents for TWIN 20 kW

Page 1: ...2016 04 02 EN 0000000302 V 001 X 36 0 2303 93412 001 TWIN pellet burner 20 26 kW Operation ...

Page 39: ...ETAtouch controller TWIN function block 39 ...

Page 49: ...ETAtouch controller Buffer function block 49 ...

Page 53: ...ETAtouch controller Hot water tank function block 53 ...

Page 57: ...ETAtouch controller Fresh water module function block 57 ...

Page 81: ......

Page 82: ...www eta co at ...

Page 83: ......

Page 84: ...www eta co at ...