36

www.eta.co.at

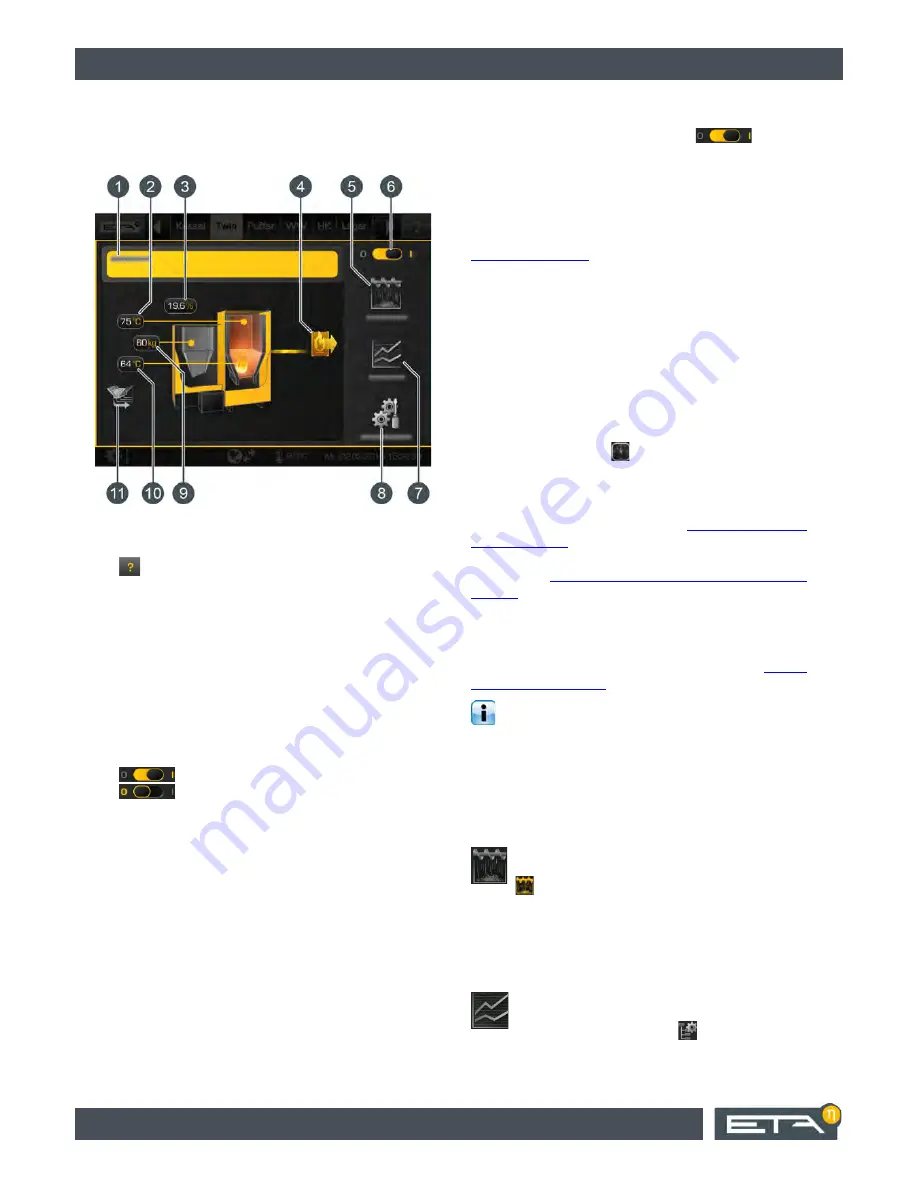

[TWIN] function block

ETAtouch controller

9.3

[TWIN] function block

Boiler overview

1

Operating condition and information.

A description of the operating conditions can be

found in the integrated Help menu by pressing the

button.

2

Flow temperature

3

Residual oxygen content of flue gas

4

Boiler consumers

If the pellet burner is in heating mode, a line

appears, and the flow temperature and the symbol

of the consumer are shown in yellow.

5

[De-ash] button.

This starts an additional de-ashing of the pellet

burner.

6

On/Off switch of the pellet burner.

= switched on or enabled

= switched off

7

[Measurement] button.

This opens the menu for emission measurement of

the pellet burner.

8

[Settings] button.

In this menu, the settings and functions most

commonly used can be stored.

9

Pellet stock in boiler.

If the amount of pellets in the pellet bin drops below

the minimum, the suction turbine starts and refills

the pellet bin.

10 Return temperature

11 Producer for the pellet burner (pellet store)

Boiler functionality

If the pellet burner is turned on (

) it is in

standby mode ([Ready] operating condition) and the

ETA control system can start it when necessary. The

pellet burner starts once the buffer demands heat, the

log boiler is not supplying heat, and no wood has been

added and ignited within the adjustable time period

[Start lag] (factory setting 10 minutes, see chapter

9.3.2.1 "Start lag"

). There is no need for manual

switching between log and pellet operation.

Once the heat is delivered to the consumer, a yellow

line appears beside the symbol of the consumer in the

overview. The minimum operating time of the pellet

burner is 30 minutes. If there is no heat demand, the

heating operation is completed upon burnout. The

operating condition changes to [Ember burnout] and

then back to standby.

The pellet bin on the boiler is automatically topped up

as soon as the stock of pellets falls below a minimum

limit. The [Fill-up time]

button sets the daily time for

complete refilling of the boiler pellet bin, if pellets have

been used up.

Boiler de-ashing takes place automatically within an

adjustable interval. See chapter

9.3.2.3 "Boiler de-

ashing interval"

. De-ashing can also be disabled for a

time, e.g. to prevent the boiler from de-ashing at night.

See chapter

9.3.2.2 "Setting the idle time for boiler de-

ashing"

.

After a certain, configurable quantity of pellets has

been consumed, the control system issues a reminder

to empty the ash box. If the ash box is only partially full,

this quantity can be increased. See chapter

9.3.2.4

"Empty ash box after"

.

If the insulating door of the log boiler stays open

longer than 1 minute, the control system switches

the pellet burner off on the assumption that the log

boiler will be filled.

9.3.1

Operating elements

[De-ash] button

Thus, an additional boiler de-ashing is started.

When active, the button is highlighted in yellow

. If the boiler is in operation, burnout first

takes place when this button is pressed, and de-ashing

only after this. If the boiler is switched off or on standby,

de-ashing can be started straight away.

[Measurement] button

When this button is pressed, a settings window

appears for the emission measurement. Using

the [Begin measurement]

button, a date for

sweeping of the chimney can be selected. The boiler

will then start in time to reach the operating

Summary of Contents for TWIN 20 kW

Page 1: ...2016 04 02 EN 0000000302 V 001 X 36 0 2303 93412 001 TWIN pellet burner 20 26 kW Operation ...

Page 39: ...ETAtouch controller TWIN function block 39 ...

Page 49: ...ETAtouch controller Buffer function block 49 ...

Page 53: ...ETAtouch controller Hot water tank function block 53 ...

Page 57: ...ETAtouch controller Fresh water module function block 57 ...

Page 81: ......

Page 82: ...www eta co at ...

Page 83: ......

Page 84: ...www eta co at ...