13

Molift Partner 255 / www.etac.com

Maintenance

Cleaning and disinfection

Clean on a regular basis. Clean surfaces with

a damp cloth using an appropriate pH-neutral

detergent. Do not use solvents or strong liquids,

this may damage surfaces on the lifter. For

disinfection when needed; use isopropyl alcohol.

Avoid abrasive cleaning products. Check

emergency stop and emergency lowering after

cleaning. The lift should not be exposed to run-

ning water.

Make sure not to damage or

remove labels when cleaning.

Reconditioning

Follow cleaning and installation procedure, com-

plete periodic inspection and use checklist after

installation to recondition the lifter.

Recycling

Refer to “Recycling instructions” for how to

properly dispose of product. This can be found on

www.etac.com.

Spare Parts

A list of spare parts is available on request.

Periodic Inspection Scope

Periodic inspection is a visual examination (par-

ticularly of the hoist’s load bearing structure and

lifting mechanism with attachments, brakes, con-

trols, safety devices and person-support devices)

according to Periodic Inspection Report for Molift

Air. This can be found on www.etac.c

.

Periodic Inspection shall be performed at least

once a year or more frequently if required by local

requirements. The inspection must be performed

by service personnel authorized by Etac. Contact

Etac for training and authorization or recommen-

dation of an approved service partner.

When performing a periodic inspection, the

inspector shall fill out the inspection report for

Molift Air. The reports should be retained by the

person(s) responsible for servicing the hoist. If

the inspection reveals defects and damages, the

owner shall be notified and a copy of the report

should be sent to Etac, molift@etac.com.

In the event of danger to safety,

the hoist shall immediately be

taken out of service and marked

clearly with “out of order” and

shall not be used until the hoist is

repaired

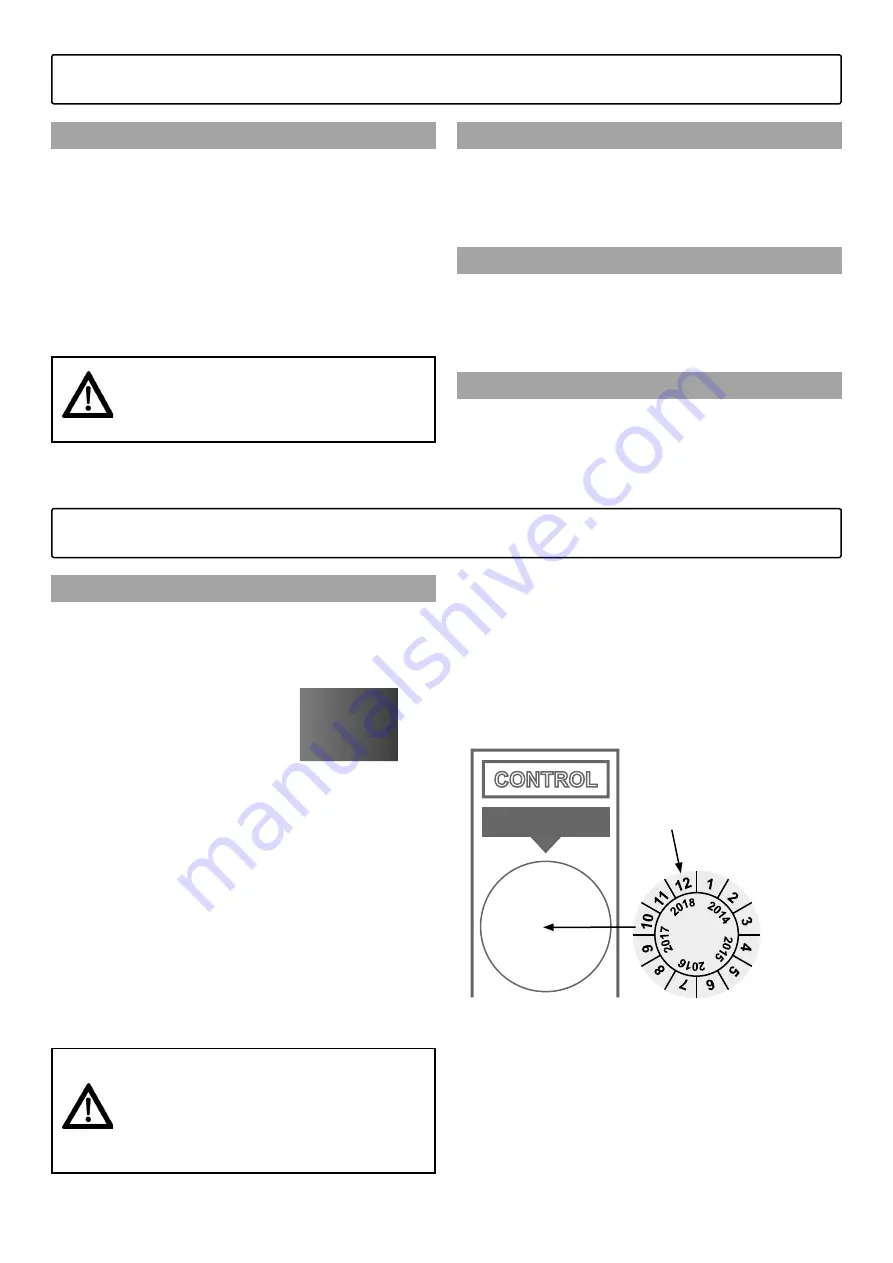

When periodic inspection is completed the

inspector shall mark the hoist with a sticker on

the control label showing the date when periodic

inspection is performed. The control label can be

found on the inside of the Side cover, and this

will then indicate when next service should be

performed.

CONTROL

12 Month

Mark label

with month

and year of

inspection

Periodic Inspection