409-35011

Rev D

65

of 83

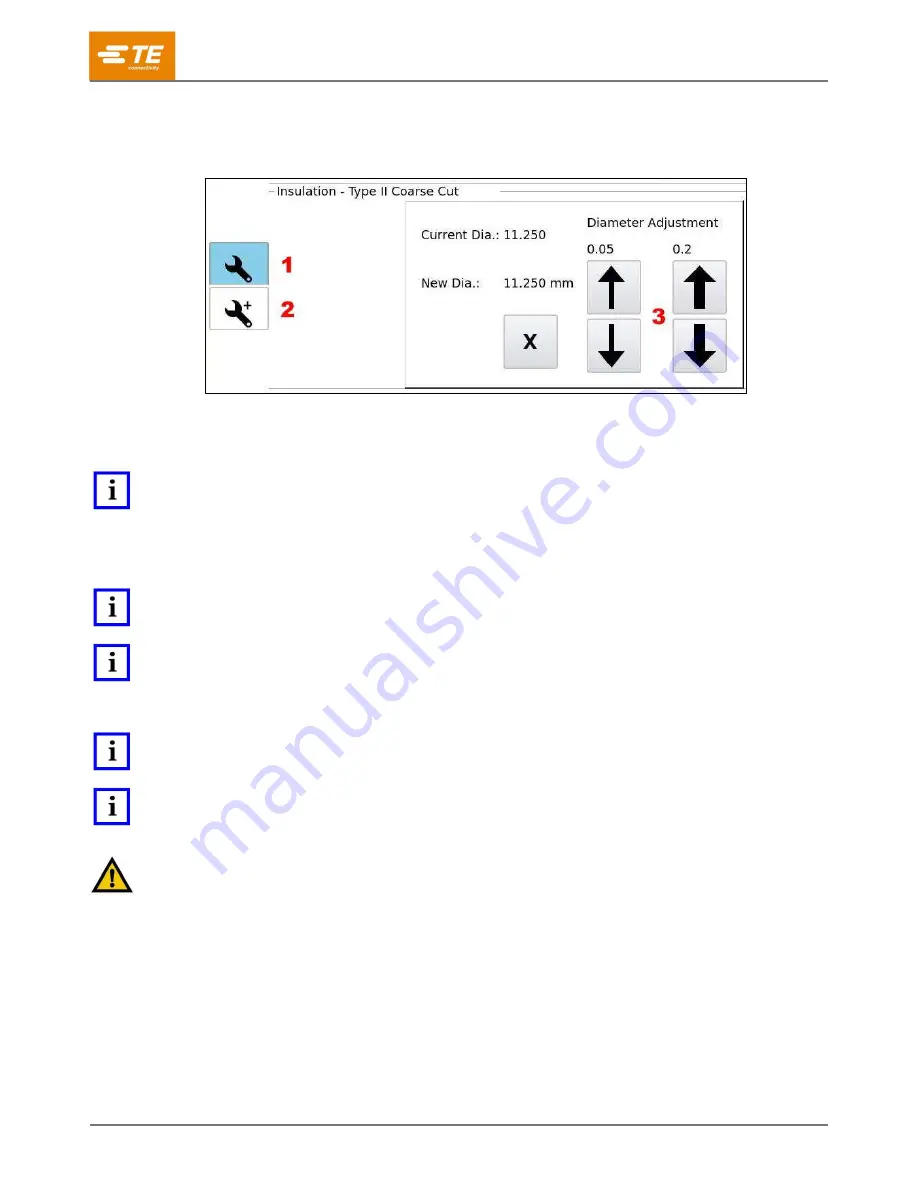

3. On the right side, use the up and down Diameter Adjustment arrows (Figure 80) to set the blade

and cutting wheel depths.

Figure 80: Standard settings

1

Standard settings

2

Advanced settings

3

Diameter adjustment arrows

NOTE

The wrench icon with no + is highlighted in blue, indicating that Standard Settings is selected (and Advanced Settings is not).

4. When changes are complete, switch the Operational Mode to Production (Figure 78). In this

mode, all changes are continuously saved. No save confirmation is required to save the changes

and run the article.

NOTE

The machine must be Homed before it allows another cycle to run.

NOTE

When tooling is changed, an article adjustment/verification will need to be performed to ensure the parameters have not

changed to continue with the production run of the article. Verification is automatic, and status is displayed on the production

screen.

NOTE

You can adjust the strip lengths by editing the fields in the Cable Builder (Figure 74 and Figure 75).

NOTE

Insulation

–

Type II Coarse Cut, Insulation

–

Coarse Cut (outer insulation), and Insulation

–

Coarse Cut (inner insulation) all

use independent Diameter Adjustments identical to the one shown in Figure 80.

CAUTION

Scrap can get stuck in the machine or scrap tube, especially when testing a new cycle. If this happens, you must stop the

cycle, shut off and lock out the main power switch (Figure 4) and air valve (Figure 6), and then clear the scrap from the

machine area, the blades, or the scrap tube to ensure nothing jams or causes damage to the blades, wheels, or cutting arms.