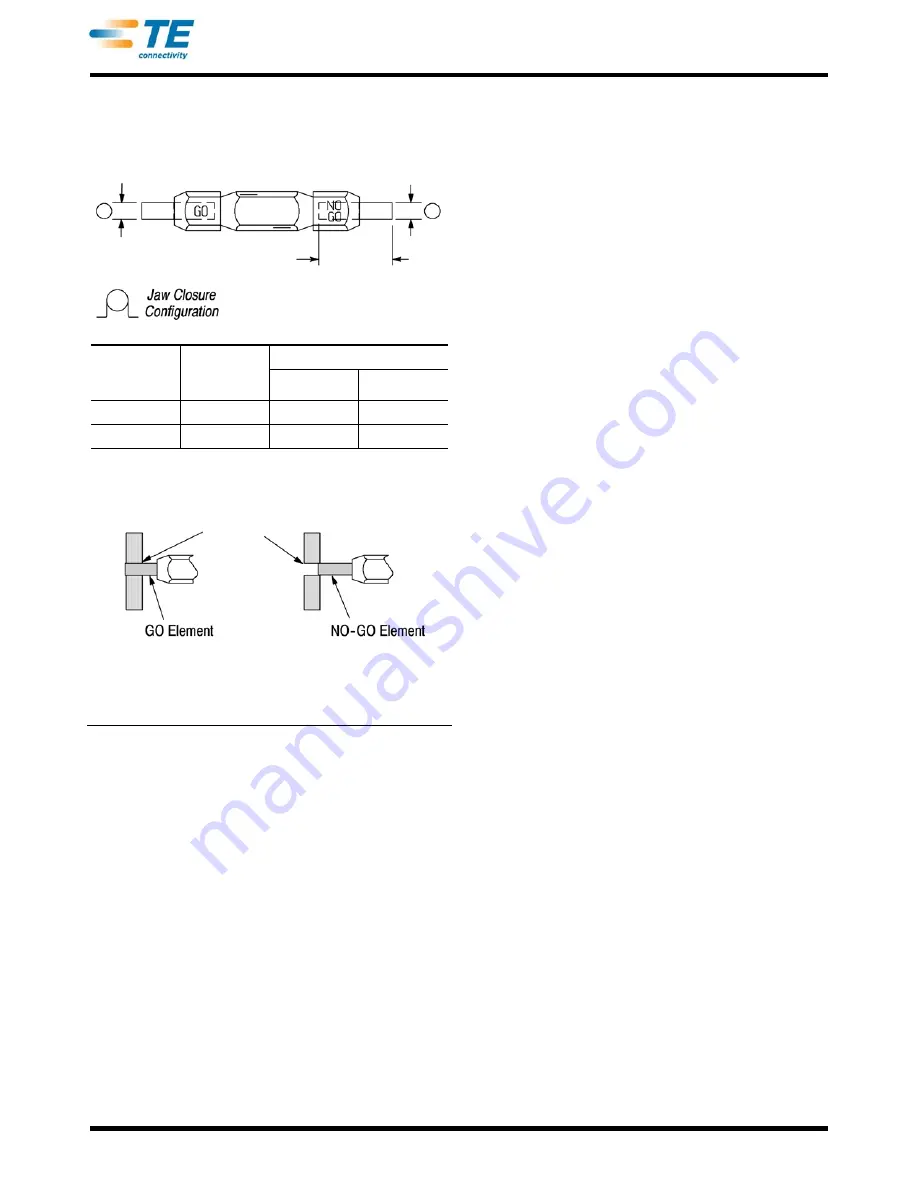

Suggested Plug Gage Design

GO

Diameter

NO-GO

Diameter

19.05 [.750]

Min Typ

TOOL

NO.

CRIMPING

CHAMBER

MARKING

GAGE ELEMENT DIAMETER

GO

NO-GO

90025

20-16

2.16 [.085]

2.31 [.091]

90026

24-22

1.600 [.063]

1.75 [.069]

Inspection of the Crimping Chamber

Crimping

Chamber

GO element must

pass completely

through the crimping

chamber.

NO-GO element may enter

partially, but must not pass

completely through the

crimping chamber.

408-1809

4 of 5

Rev B

Figure 4

D. Ratchet Inspection

Obtain a 0.025 [.001] shim that is suitable for checking

the clearance between the bottoming surfaces of the

crimping jaws and proceed as follows.

1. Select a terminal and a wire (maximum size) for

the tool you are using (see Figure 2).

2. Position the terminal and wire between the

crimping jaws, according to Section 3, CRIMPING

PROCEDURE (Steps 1 through 5). Holding the wire

in place, squeeze the tool handles together until the

CERTI-CRIMP ratchet releases. Hold the tool

handles in this position, maintaining just enough

pressure to keep the jaws closed.

3. Check the clearance between the bottoming

surfaces of the crimping jaws. If the clearance is

0.025 [.001] or less, the ratchet is satisfactory. If

clearance exceeds 0.025 [.001], the ratchet is out of

adjustment and must be repaired (see Section 6,

REPLACEMENT AND REPAIR).

If the tool conforms to these inspection procedures,

lubricate it with a THIN coat of any good SAE† 20

motor oil and return it to service.

6. REPLACEMENT AND REPAIR

Customer-replaceable parts are listed in Figure 5.

Parts other than those listed in Figure 5 should be

replaced by TE to ensure quality and reliability of the

tool. Order replacement parts through your TE

representative, or call 1-800-526-5142, or send a

facsimile of your purchase order to 1-717-986-7605, or

write to:

† Society of Automotive Engineers

CUSTOMER SERVICE (038-035)

TYCO ELECTRONICS CORPORATION

PO BOX 3608

HARRISBURG PA 17105-3608

For customer repair service, call 1-800-526-5136.

7. REVISION SUMMARY

Revisions to this instruction sheet include:

•

Changed company name and logo