Installation and Safety Manual of CIGS-3000A1&E1 Solar Photovoltaic Module

This document and all information contained herein is the sole property of ETERBRIGHT SOLAR CORPORATION and shall not be distributed, reproduced, or

disclosed in whole or in part without the prior written consent of ETERBRIGHT SOLAR CORPORATION.

A3-224

load is 1600 Pa (tested to withstand 2400 Pa according to UL 1703) and to withstand

2400 Pa wind/snow load requirement according to IEC 61646.

Any module without a frame (laminate) shall not be considered to comply with the

requirements of UL 1703 unless the module is mounted with hardware that has been

tested and evaluated with the module under this standard or by a field Inspection

certifying that the installed module complies with the requirements of UL 1703.

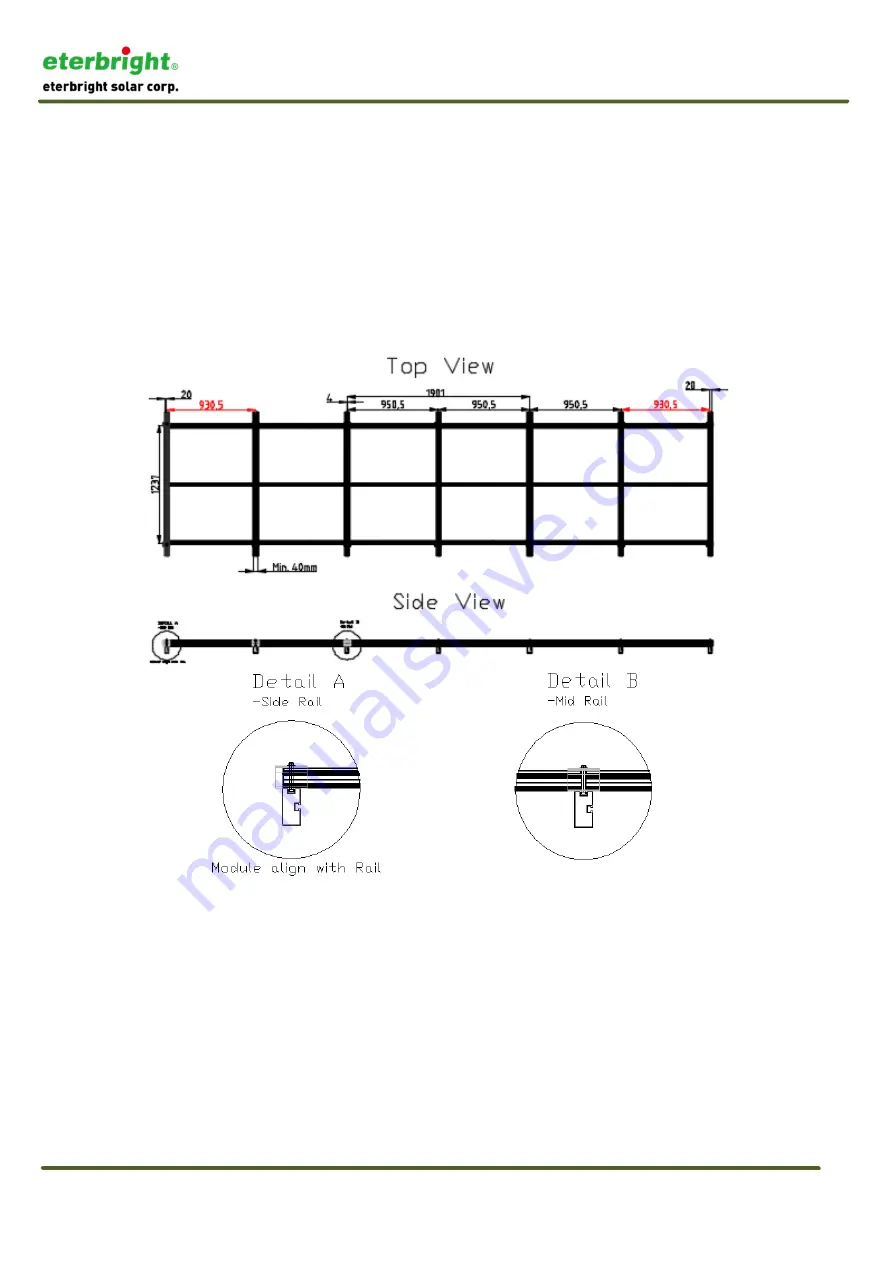

Clamps required with M8 (5/16 in) bolts. Selected clamps, bolts, nuts and other parts

must be corrosion-resistant materials.

To mount onto the support structure has two steps. The first step, to apply torque of 10

Nm(88.5lb-in) for pre-fix the clamps and module on support structure. The second

step, to apply torque of 20 Nm(177lb-in) to secure the module to support structure

,

and pay attention as the clamps CANNOT touch the glass

.

Figure 8.1The positions of the mounted clamps and supportive rails