5

www.etna.com.tr

10. Liquid Level Higher Than the Booster or

At The Same Level

Close the discharge valve, remove the fill/bleed plug and

open the suction valve until the water flows out of the fill/

bleed plug. Then close the plug.

11. Liquid Level Lower Than the Pump

(Negative Suction)

Close the discharge valve, remove the fill/bleed plug

and by means of a funnel fill the water, close the plug.

Note : Adjust the float switch according to the size of

the tank. (Page 9)

12. Checking the Rotation Three-Phase

Motors

After connecting and filling, start the pump with the

discharge valve closed and check that the rotation

direction is correct (shown on the coupling and the

motor) through the coupling protection or fan cover. If

the direction of rotation is not correct, stop the motor,

disconnect from the mains and invert two wires on the

terminal board. B

13. Operation

Start up the booster set with the discharge (delivery) gate

valve closed and fallow pump or pumps reaching to the

switched-off pressure of the unit from the manometer.

Then open the service tap and check the system pressure

is dropping and the pump or the pumps running at

the starting pressure. If everything is okay, open all the

gate valves in the delivery line and let the system under

booster-set pressure.

14. Operations Description

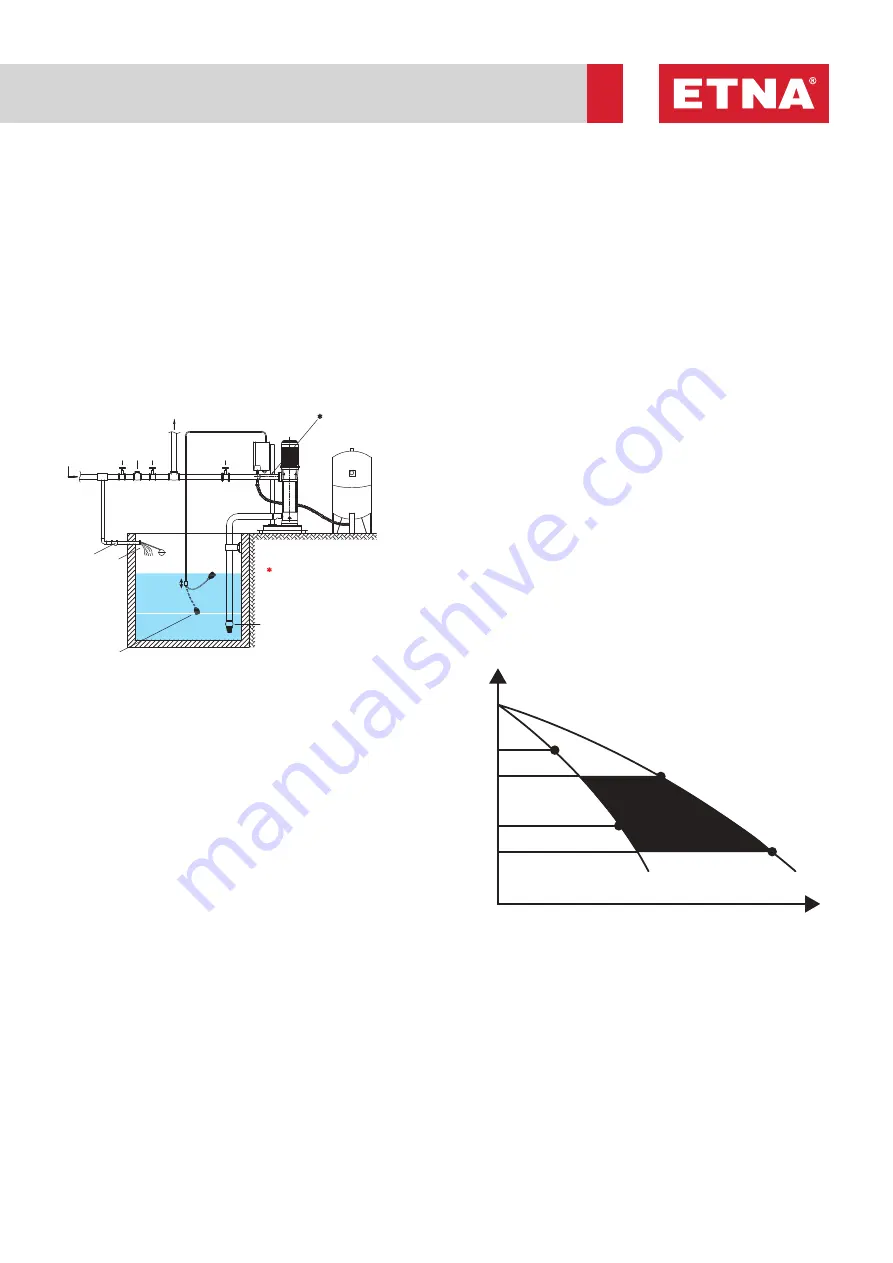

14.1 Example for two-pump sets

The starting and stopping of the pumps are determined

by the pressure values set on the pressure switches.

Each pressure switch is connected to a single pump

with a cyclic pump change over. The differential

pressure is the pressure difference between starting

pressure and switch-off pressure. It is set at the same

value for both pumps.Figure 6 shows the operating

mode with the pumps curves

On demand, water is drawn from the tank

• When the pressure drops to the P1 value the first

pump starts.

• If the water consumption increases and the

pressure drops to the P2 value, the second pump

starts.

• When consumption reduces and the pressure

increases until it reaches the P2s value, one of the

pumps is switched off.

• If consumption keeps reducing, the pump charges

the tank and stops at the P1s value.

3 and 4 pumps booster sets have the same operation

sequence

15. Fire Fighting Booster Sets

15.1 Usage

Fire fighting boosters should not be used for anything

other than fire-fighting. They should not be used for

garden irrigation, building installation, vehicle washing

etc.

1 - Valve

2- Check valve

3- Float valve

4- Float switch

5- Service tap

6- Upright valve

7- Strainer

8- Water Tank

1

1

2

2

5

3

4

* The suction pipe should be at least 15 cm above the tank bottom.

*

To the building

Mains

Operating level

Stoppage

Level

Starting-Stop

Level Setting

7

8

Important:

Check valve should not be installed on

the delivery line of the booster sets

with negative suction level. The upright

valve installed on suction also acts like

a check valve.

# A check valve should not be installed on

the delivery line of the plumbing either.

To the building

1

1

2

Mains

6

1

3

4

7

P1s

H

P2s

P1

P2

Figure 5

Figure 6

Summary of Contents for EPH B-M46 Series

Page 11: ...11 www etna com tr 22 Electric Panels for Single and Double Pump...

Page 33: ...33 www etna com tr NOTES...

Page 34: ...34 NOTES...

Page 35: ...35 www etna com tr NOTES...