11

www.etna.com.tr

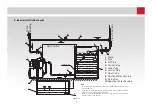

12. Electrical Installation

The electrical connections of the booster should be made by an authorized electrician. Supply line should be ensured to be sufficient, checking the voltage and

amperage values (see table in section 5.2).

• The electrical motor of the booster should be protected using a thermal overload switch. Similarly, the supply line fuses should be compatible with the motor

power. Otherwise, the motor may burn out.

• Check the ground connection of the product. This is a life-critical issue.

13. Initial Operation

• Check water supply installation and electricity connections. Check the fuses.

• If the booster is priming water from a water tank, open the suction line valves and release the air by the air discharge plug. Wait until the water reaches the

pump. Close the air discharge plug when water reaches to the pump.

• If the booster is sucking water from a well, open the air discharge plug to fill the suction line with water and then close the plug.

• Press the switch to start-up the motor.

• Wait until the pump supplies water to the booster tank and to the mains. The booster will stop automatically when it reaches the pressure indicated on the

label.

• Open a tab and wait for the pressure to drop on the manometer. The booster automatically starts up in the lower operation pressure.

• Recalibrate the pressure settings if the booster is working outside the pressure range specified on the label. You may need to do this few times before the

booster starts working right.