7

www.etna.com.tr

7. Periodic Maintenance

The booster should go through maintenance at least once (1) a year by an authorized technical service so that it can serve you longer without any problems.

Besides this regular maintenance, clean the dust accumulated on the electrical motor using a soft brush regularly. The dust accumulated on the motor may cause

the motor to overheat and burn out.

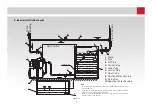

8. Connection and Assembly

Ensure that your product is mounted by authorized technicians in line with the installation layout given on the user manual. Call a technical service for starting-up

the product.

8.1. Location Selection

• The product should be placed indoors in a way that it is not exposed to external factors such as rain and frost.

• Leave at least 80cm empty space all around the product.

• Ensure that the distance to the tank that the product will prime water from is maximum 10m.

• Mount the product firmly on a strong and flat concrete surface using anchor bolts.

• Place the electrical motor to a height that enables protection from flood.